A pulverized coal pyrolysis method and device

A pulverized coal and pyrolysis technology, which is applied in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of difficult gas discharge, low gas thermal efficiency, large gas circulation volume, etc. The effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

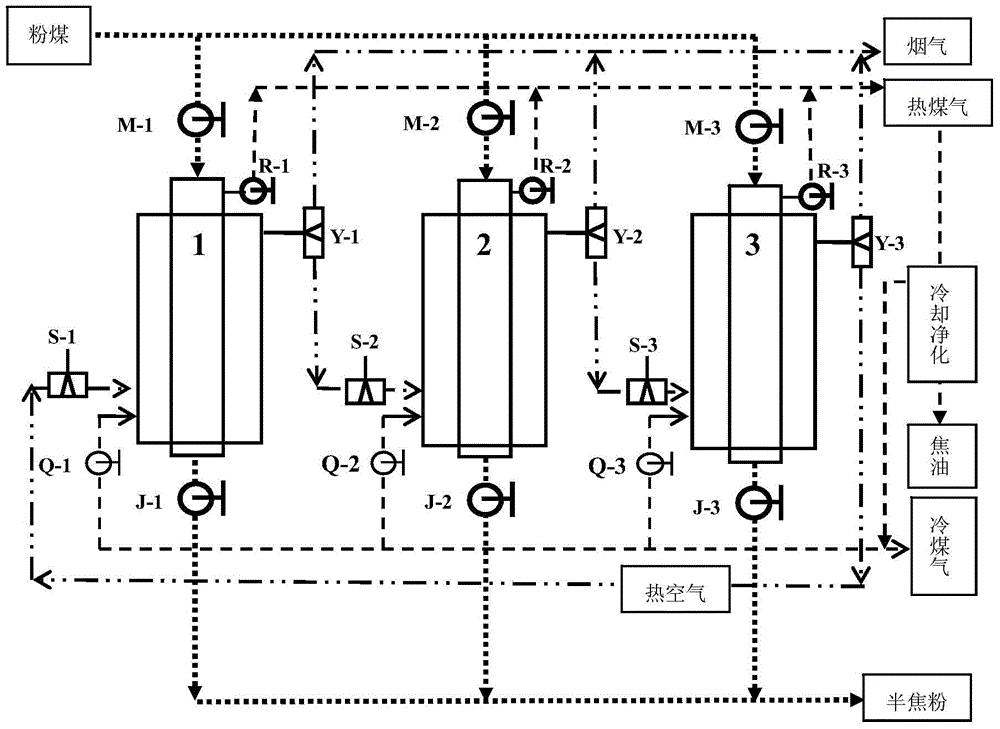

[0035] The pyrolysis method and device of this embodiment are as follows:

[0036] Use an external heat source to heat the static furnace 3 to generate high-temperature flue gas, which is used to preheat the static furnace 1. At this time, the flue gas three-way valve y-3 is closed in the direction of the flue gas pipeline, that is, closed up, leading to the direction of the three-way valve s-1 Open, the hot flue gas enters the static furnace 1, and at the same time the air inlet of the three-way valve s-1 of the static furnace 1 is closed, the flue gas in the static furnace 1 is discharged into the flue gas pipe through the three-way valve y-1, that is, it is opened upwards, y-1 is connected to s-2 to close, that is, down to close. At this time, the pulverized coal in the static furnace 1 is dried and preheated, and the steam generated by drying enters the flue gas pipeline and is purified to meet the standard and then discharged; the coal inlet valve M-1 and the outlet The c...

Embodiment 2

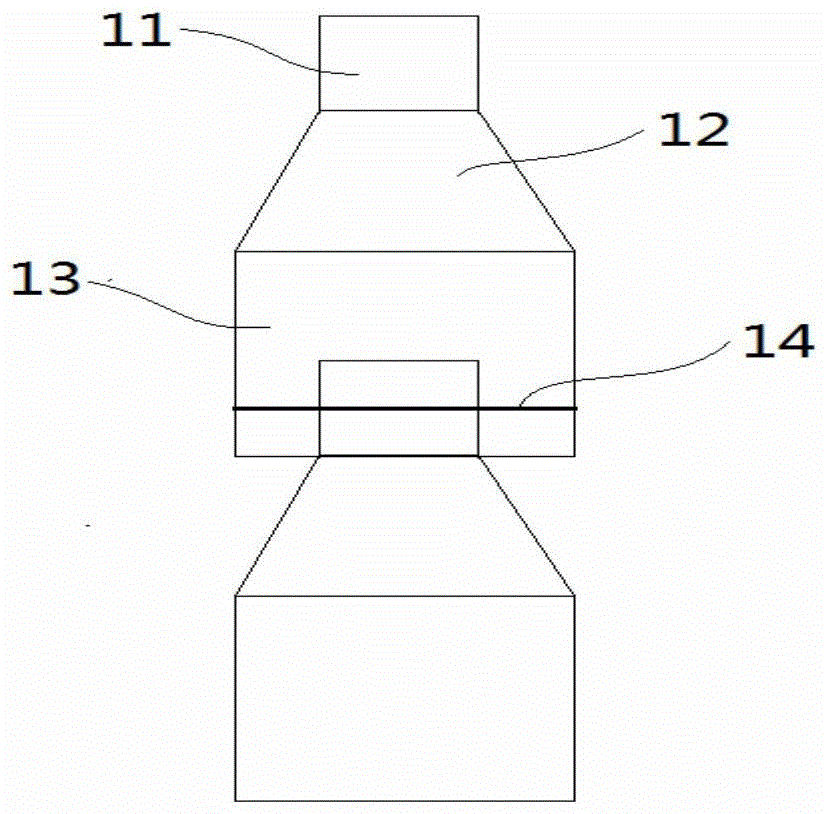

[0048] Different from Embodiment 1, the air guiding device of this embodiment includes a plurality of air guiding units, such as image 3 As shown, each air guide unit includes an upper vent 25, a lower vent 27 and a vent pipe 26, wherein the upper and lower vents are box-type structures, and the vent pipe 26 is in the shape of a truncated cone. Suspension rods 28 are also used to connect the connected air guide units.

[0049] The size of the upper air vent in this embodiment is 60×1400mm; the height of the air pipe is 100mm; the size of the lower air vent is 120×1500mm.

Embodiment 3

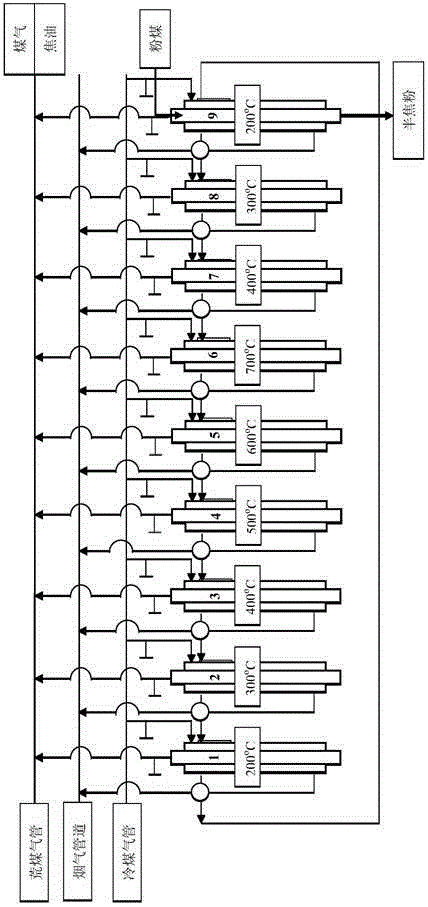

[0051] Each working unit (total three work) of this embodiment is provided with the work process of three independent furnaces, as Figure 4 As shown, at a certain moment:

[0052] 7#, 8#, 9# three independent furnaces are in cooling state;

[0053] Furnaces 6#, 5#, and 4# are in the state of pyrolysis, and the preheated air is used for combustion and pyrolysis in the 6# furnace. Furnaces 5# and 4# are also in the state of pyrolysis at the same time. The gas produced in the pyrolysis furnace enters the gas pipe and is Purify and cool to get cold gas and tar;

[0054] The 3#, 2#, and 1# furnaces whose temperature in the furnace is lower than the pyrolysis temperature are in a preheating state by using the hot flue gas discharged from the 4# furnace, and the steam generated in the three preheating furnaces is discharged into the flue gas pipe, and the 1# furnace The preheated flue gas that comes out is also discharged into the flue gas pipe at the same time.

[0055] At the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com