Pd-based alloy packaged molecular sieve catalyst, as well as preparation method and application thereof

A molecular sieve and catalyst technology, which is applied in the field of molecular sieve catalyst and preparation of encapsulated Pd-based alloys, to achieve the effects of avoiding runaway temperature, high ethylene selectivity, and shortening the diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

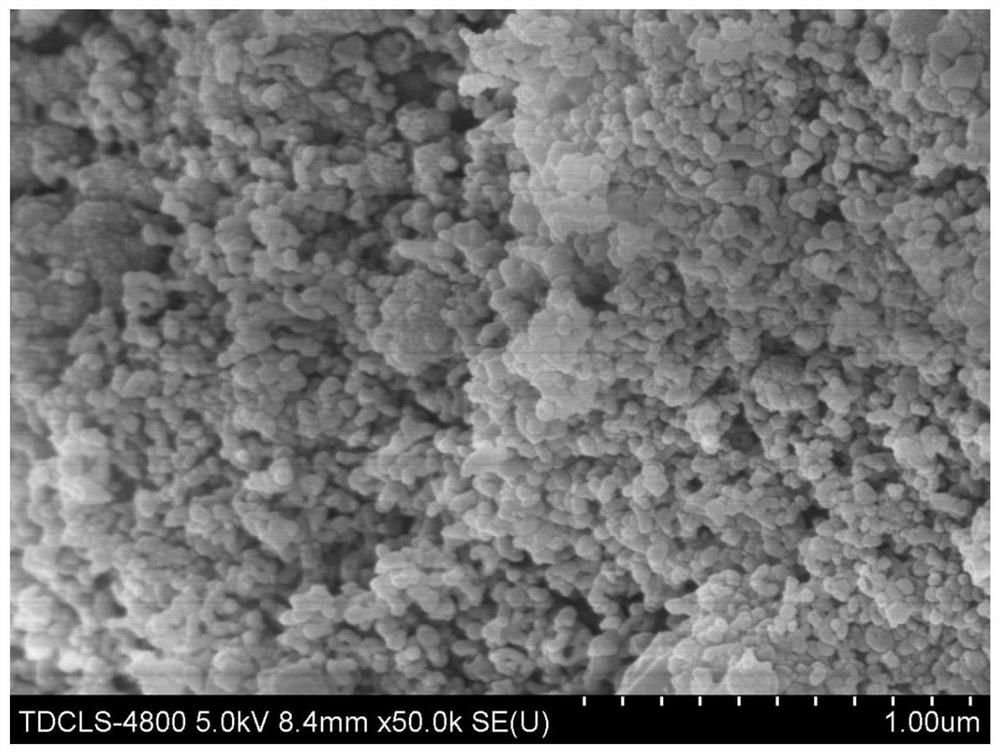

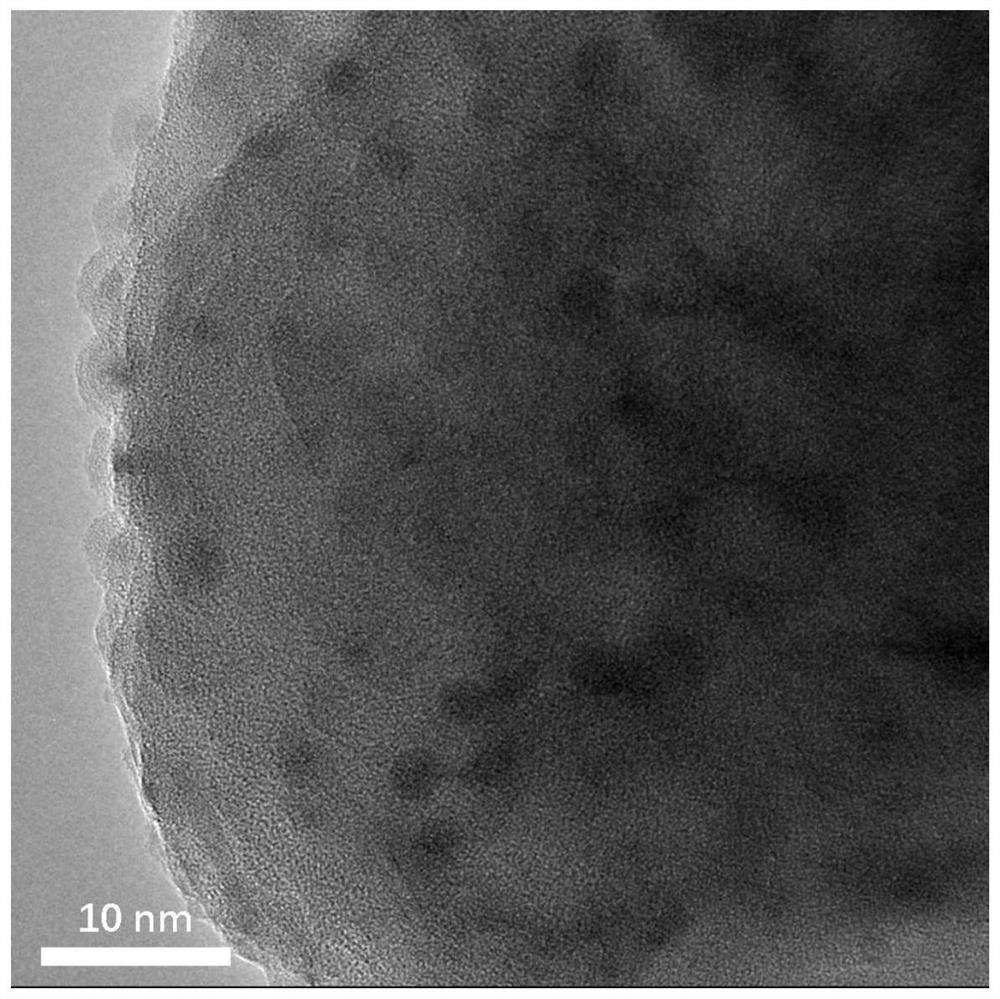

Embodiment 1

[0045] (1) Add 0.0181mol of aluminum source to 8g of water, mix uniformly to form solution A, add 0.0181mol of silicon source to 8g of water, mix uniformly to form solution B; quickly add 0.0816mol of sodium hydroxide to the solution In A, stir well, stir at room temperature for 30 minutes to form mixed solution C; add solution B dropwise to mixed solution C, and stir at room temperature for 30 minutes to form uniform mixed solution D; transfer solution D to 100mL water Heat the kettle and place it in an oven at 100°C for static crystallization for 12 hours; centrifugally wash the product with deionized water until the pH is neutral, dry at 100°C for 12 hours, and bake in a muffle furnace at 300°C for 4 hours (2°C / min heating rate) , obtain sodalite molecular sieve (SOD) powder;

[0046] (2) Palladium nitrate powder and silver nitrate powder are dissolved in deionized water adding a small amount of dilute nitric acid, and are prepared as a solution; the sodalite molecular siev...

Embodiment 2

[0070] The method of Example 1 was used for preparation and reaction, the only difference being that the loading of metal palladium in step (2) was 0.4wt%.

Embodiment 3

[0072] Preparation and reaction were carried out by the method of Example 1, the only difference being that the loading of metal palladium in step (2) was 0.1wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com