Large-width aluminum alloy ribbed plate, production method thereof and extrusion perforating needle

A technology of aluminum alloy strips and production methods, applied in the direction of furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of poor mechanical properties and corrosion resistance of 5-series aluminum alloys for ships, and the inability to produce ribbed plates for ships, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

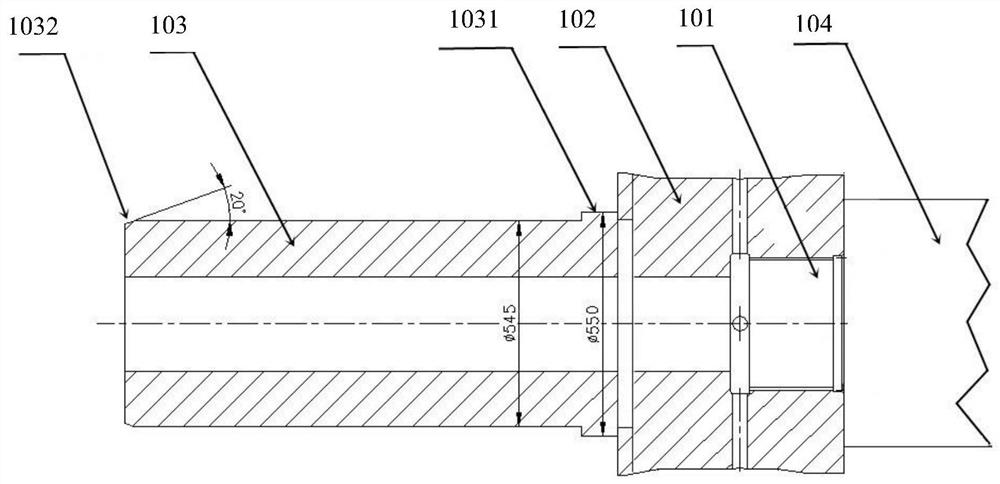

[0094] In this example, an extruded perforating needle for the preparation of large and wide aluminum alloy ribbed panels is used, and its structural schematic diagram is shown in figure 1 , including a solid connecting shaft 101, the solid connecting shaft 101 is covered with an integrated extrusion pad 102, the two sides of the solid connecting shaft 101 are respectively screwed with the extrusion rod 104 and the extrusion follower pin 103, and the solid connecting shaft 101, extrusion The rod 104 and the extrusion follower pin 103 are coaxial, and the extrusion follower needle 103 is a hollow cylindrical structure with an outer diameter of Φ545mm.

[0095] A 20° chamfer 1032 is provided at the end of the extruding follower pin 103 away from the solid connecting shaft 101, and an annular overpressure step 1031 is provided at the root of the extruding follower pin 103 close to the solid connecting shaft 101. The outer diameter of the overpressure step 1031 is Thicker than ext...

Embodiment 2

[0109] A method for producing a large and wide aluminum alloy ribbed plate, comprising the steps of:

[0110] S1. Ingredients: Prepare aluminum alloy raw materials according to the following weight ratios, Si: 0.05%, Fe: 0.13%, Cu: 0.01%, Mn: 1.0%, Mg: 6.3%, Ti: 0.08%, Zr: 0.06%, Zn: 0.02%, the balance is Al and unavoidable impurities, among which, a single element in the impurity: ≤0.05%, the total of impurity elements: ≤0.15%;

[0111] S2. Melting and casting: Add the prepared aluminum alloy raw materials into the melting furnace in the order of small material first, large material first, high melting point first, and then low melting point. After melting, the aluminum alloy melt is poured into the mold for casting to obtain aluminum alloy casting. ingot;

[0112] S3. Boring and sawing: Bore the aluminum alloy ingot to make a hollow aluminum alloy ingot. The inner diameter of the ingot is Ingot outer diameter

[0113] S4. Preheating: Divide the aluminum alloy hollow in...

Embodiment 3

[0123] A method for producing a large and wide aluminum alloy ribbed plate, comprising the steps of:

[0124] S1. Ingredients: prepare aluminum alloy raw materials according to the following weight ratios, Si: 0.07%, Fe: 0.15%, Cu: 0.05%, Mn: 0.9%, Mg: 6.5%, Ti: 0.06%, Zr: 0.05%, Zn: 0.01%, the balance is Al and other unavoidable impurities, single impurity element: ≤0.05%, total impurity elements: ≤0.15%;

[0125] S2. Melting and casting: Add the prepared aluminum alloy raw materials into the melting furnace in the order of small material first, large material first, high melting point first, and then low melting point. After melting, the aluminum alloy melt is poured into the mold for casting to obtain aluminum alloy casting ingot;

[0126] S3. Boring and sawing: Bore the aluminum alloy ingot to make a hollow aluminum alloy ingot. The inner diameter of the ingot is Ingot outer diameter

[0127] S4. Preheating: Divide the cross section of the aluminum alloy hollow ingot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com