Light-emitting-adjustable silicate fluorescent powder and preparation method thereof

A fluorescent powder and silicate technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of luminous efficiency and color reproduction performance, different forward voltage and light output, and large color temperature differences between modules, etc., to achieve good Chemical and thermal stability and luminous intensity, luminous color adjustable, simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

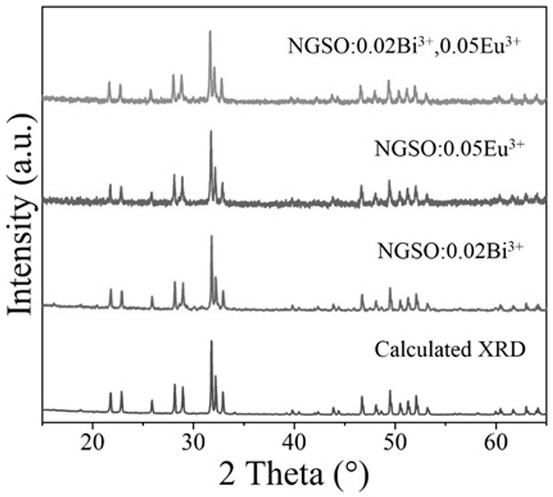

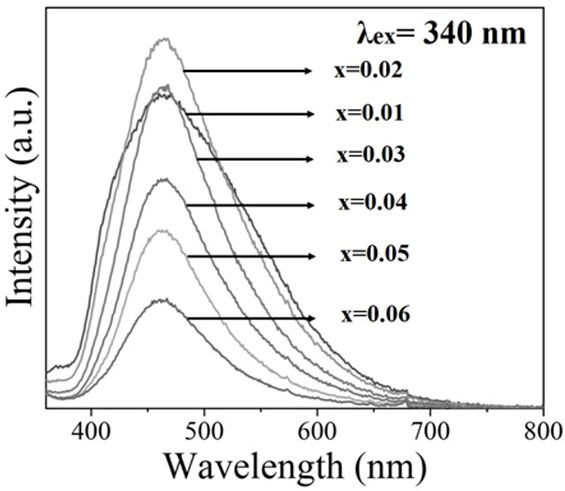

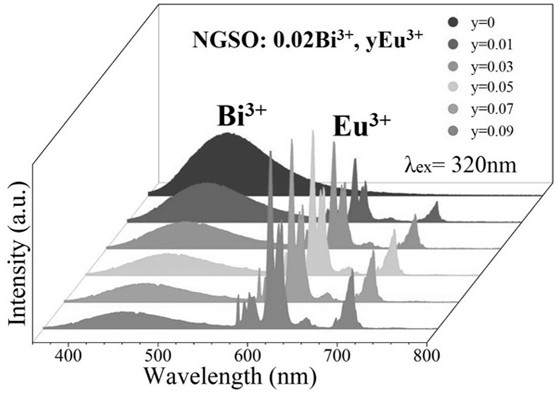

[0032] A Silicate Phosphor NaGd with Tunable Luminescence 9 (SiO 4 ) 6 o 2 :0.02Bi 3+ ,0.05Eu 3+ The preparation, its steps are as follows:

[0033] 1) Weigh the solid Na respectively 2 CO 3 0.5mol, Gd 2 o 3 4.5mol, SiO 2 6mol, Bi 2 o 3 0.01mol, Eu 2 o 3 0.025mol;

[0034] 2) Put the weighed drug into an agate mortar, add 3 mL of absolute ethanol and grind for 15 minutes to mix the drug evenly to obtain mixture A;

[0035]3) Put the mixture A prepared in step 2) into an alumina crucible (25mm×25mm×30mm), and dry it in a drying oven at 55°C for 20 minutes;

[0036] 4) Put the mixture A prepared in step 3) in a high-temperature box-type resistance furnace, raise the temperature from room temperature to 500°C at a rate of 5°C / min, keep it warm for 20 minutes, and then increase the temperature at a rate of 5°C / min To 1300°C, keep warm for 6h, then cool down to room temperature with the furnace;

[0037] 5) Put the substance reacted in step 4) in a mortar and g...

Embodiment 2

[0039] A Silicate Phosphor NaGd with Tunable Luminescence 9 (SiO 4 ) 6 o 2 :0.02Bi 3+ ,0.05Eu 3+ The preparation, its steps are as follows:

[0040] 1) Weigh the solid Na respectively 2 CO 3 0.5mol, Gd 2 o 3 4.5mol, SiO 2 6mol, Bi 2 o 3 0.01mol, Eu 2 o 3 0.025mol;

[0041] 2) Put the weighed drug into an agate mortar, add 3 mL of absolute ethanol and grind for 15 minutes to mix the drug evenly to obtain mixture A;

[0042] 3) Put the mixture A prepared in step 2) into an alumina crucible (25mm×25mm×30mm), and dry it in a drying oven at 60°C for 15 minutes;

[0043] 4) Put the mixture A prepared in step 3) in a high-temperature box-type resistance furnace, raise the temperature from room temperature to 500°C at a rate of 5°C / min, keep it warm for 20 minutes, and then increase the temperature at a rate of 5°C / min To 1350°C, keep warm for 6h, then cool down to room temperature with the furnace;

[0044] 5) Put the substance reacted in step 4) in a mortar and ...

Embodiment 3

[0046] A Silicate Phosphor NaGd with Tunable Luminescence 9 (SiO 4 ) 6 o 2 :0.02Bi 3+ ,0.05Eu 3+ The preparation, its steps are as follows:

[0047] 1) Weigh the solid Na respectively 2 CO 3 0.5mol, Gd 2 o 3 4.5mol, SiO 2 6mol, Bi 2 o 3 0.01mol, Eu 2 o 3 0.025mol;

[0048] 2) Put the weighed drug into an agate mortar, add 3mL of absolute ethanol and grind for 20 minutes to mix the drug evenly to obtain mixture A;

[0049] 3) Put the mixture A prepared in step 2) into an alumina crucible (25mm×25mm×30mm), and dry it in a drying oven at 55°C for 20 minutes;

[0050] 4) Put the mixture A prepared in step 3) in a high-temperature box-type resistance furnace, raise the temperature from room temperature to 500°C at a rate of 5°C / min, keep it warm for 20 minutes, and then increase the temperature at a rate of 5°C / min To 1400°C, keep warm for 5h, then cool down to room temperature with the furnace;

[0051] 5) Put the substance reacted in step 4) in a mortar and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com