Preparation method of red fluorescent powder

A red phosphor and phosphor technology, applied in the field of fluorescent materials, can solve the problems of poor particle dispersibility, difficult control of shape and size, etc., and achieve the effects of dense particles, easy control of shape and size, and reliable implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] According to chemical formula (Sr 0.9 Ca 0.06 Nb 0.04 ) Si 2 Al 3 N 5 o 3 The stoichiometric ratio weighs analytically pure Al 2 o 3 , Si 3 N 4 , SrO, CaO and Nb 2 o 3 , Grind and mix the above principles and press it into a green body, and pre-fire it at 800°C for 3 hours in an air atmosphere. The calcined product is ground and crushed, and 10% of BaF is added 2 As a molten salt medium, it is calcined for the second time under nitrogen atmosphere, the nitrogen pressure is 0.6Mpa, the calcining temperature is 1700°C, and the time is 6 hours. The calcined product was washed three times with 10% hydrochloric acid and deionized water, and dried to obtain the product.

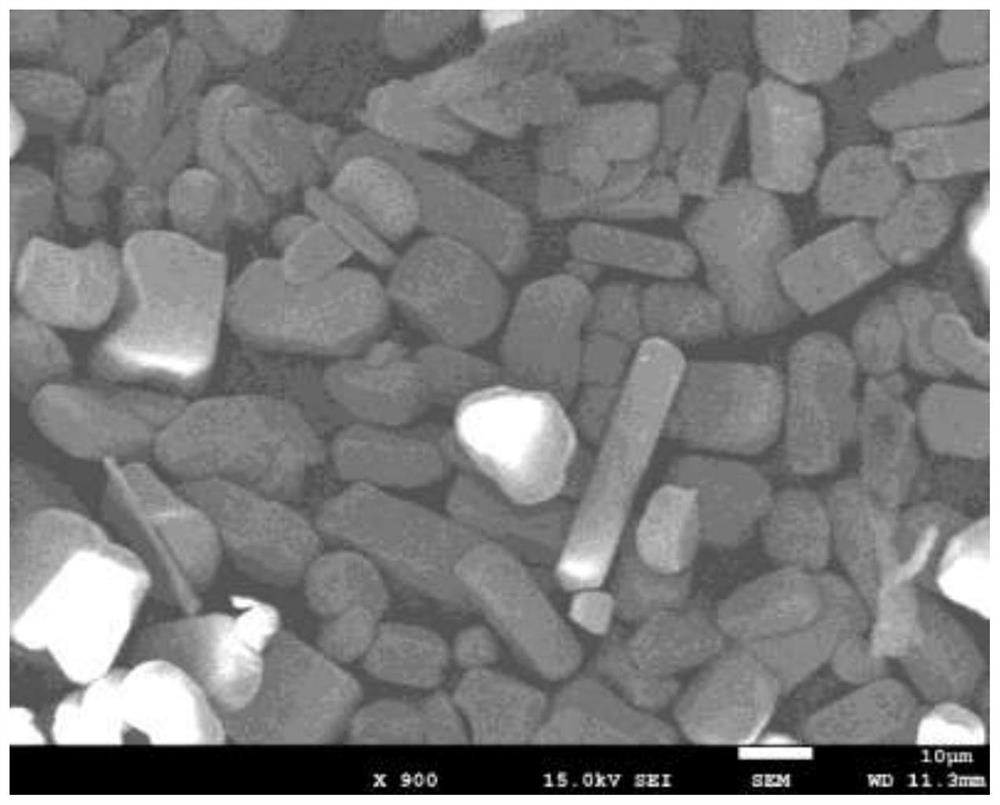

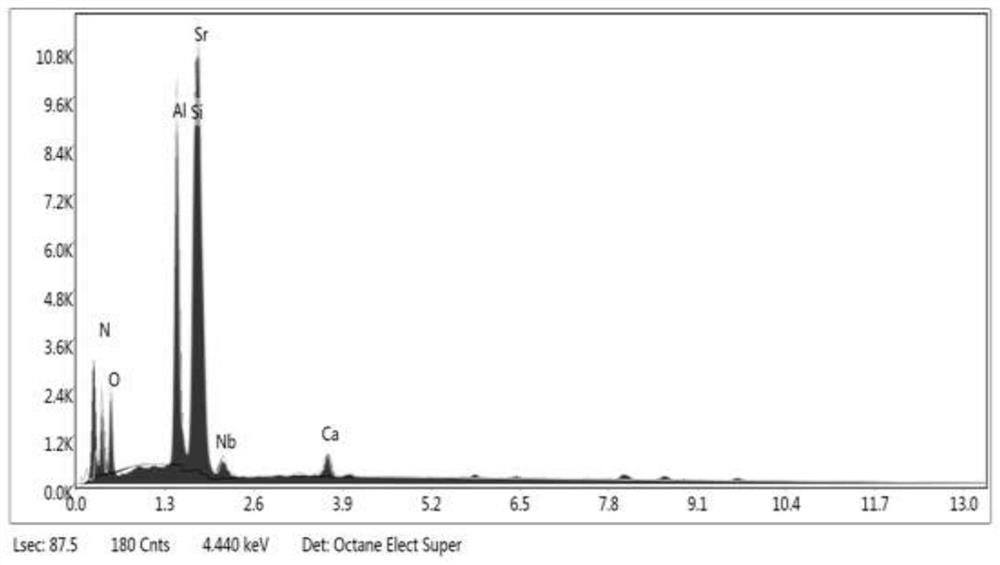

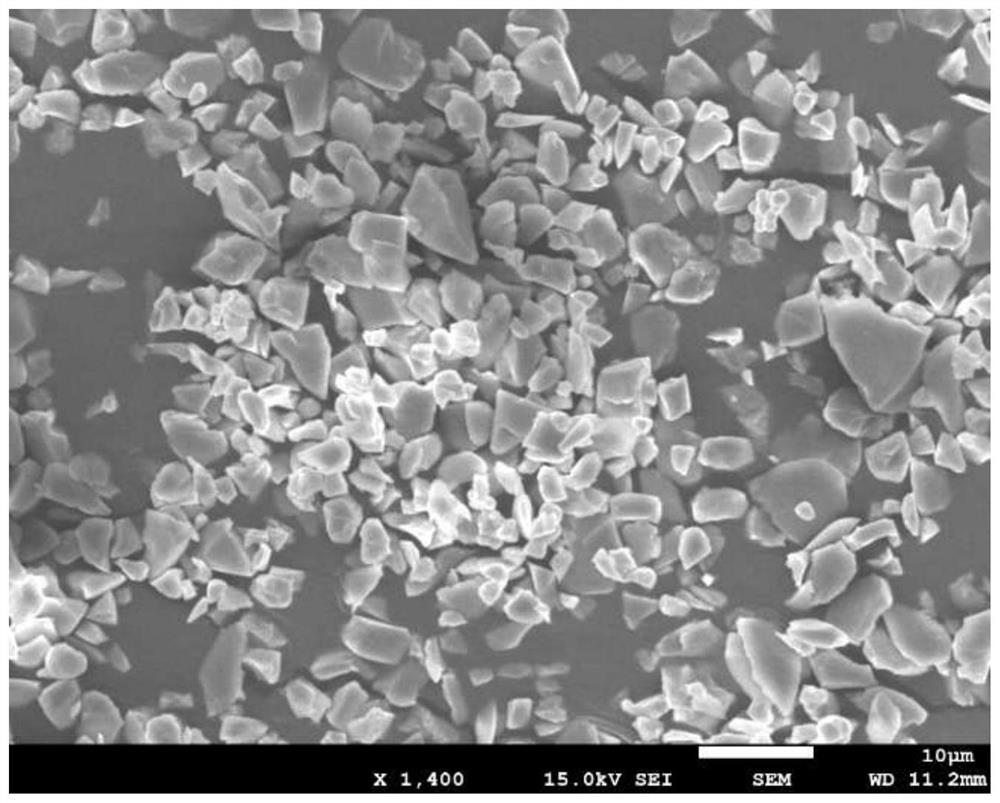

[0020] from figure 1 with figure 2 Look, the final product particles are independently dispersed, with high density, no impurities, and high purity.

Embodiment 2

[0022] According to chemical formula (Sr 0.95 Ce 0.05 )Si1Al 4 N 4 o 5 The stoichiometric ratio weighs analytically pure Al 2 o 3 , Si 3 N 4 , SrCO 3 and CeO 2 Grind and mix the above principles to form an embryo body, and pre-fire at 900°C for 4 hours in an air atmosphere. The calcined product is ground and broken, and 5% BaF is added 2 As a molten salt medium, it is calcined for the second time under nitrogen atmosphere, the nitrogen pressure is 0.8Mpa, the calcining temperature is 1800°C, and the time is 4 hours. The calcined product was washed three times with 10% hydrochloric acid and deionized water, and dried to obtain the product. In Example 2, a pure substance was also obtained without impurity elements. The obtained emission spectra were compared with (Sr 0.95 Ce 0.05 )Si1Al 4 N 4 o 5 unanimous.

Embodiment 3

[0024] According to the chemical formula SrSi1Al 4 N 2 o 6 The stoichiometric ratio weighs analytically pure Al 2 o 3 , Si 3 N 4 , SrCO 3 , Grind and mix the above principles and press it into a green body, and pre-fire it at 900°C for 3 hours in an air atmosphere. The calcined product is ground and broken, and 8% BaF is added 2 As a molten salt medium, it is calcined for the second time under nitrogen atmosphere, the nitrogen pressure is 0.5Mpa, the calcining temperature is 1900°C, and the time is 8 hours. The calcined product was washed three times with 10% hydrochloric acid and deionized water, and dried to obtain the product.

[0025] In Example 3, a pure substance was also obtained without impurity elements, and the particles were independently dispersed with high density.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com