A kind of vanadium-based SCR catalyst regenerated catalytic powder and preparation method thereof

A technology of SCR catalyst and catalytic powder, which is applied in the field of regenerated catalytic powder and preparation, can solve the problems of increased oxidation rate, increased regeneration cost, acceleration performance, etc., and achieve the effects of solving sintering agglomeration, solving pollution hazards, and being easy to operate and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

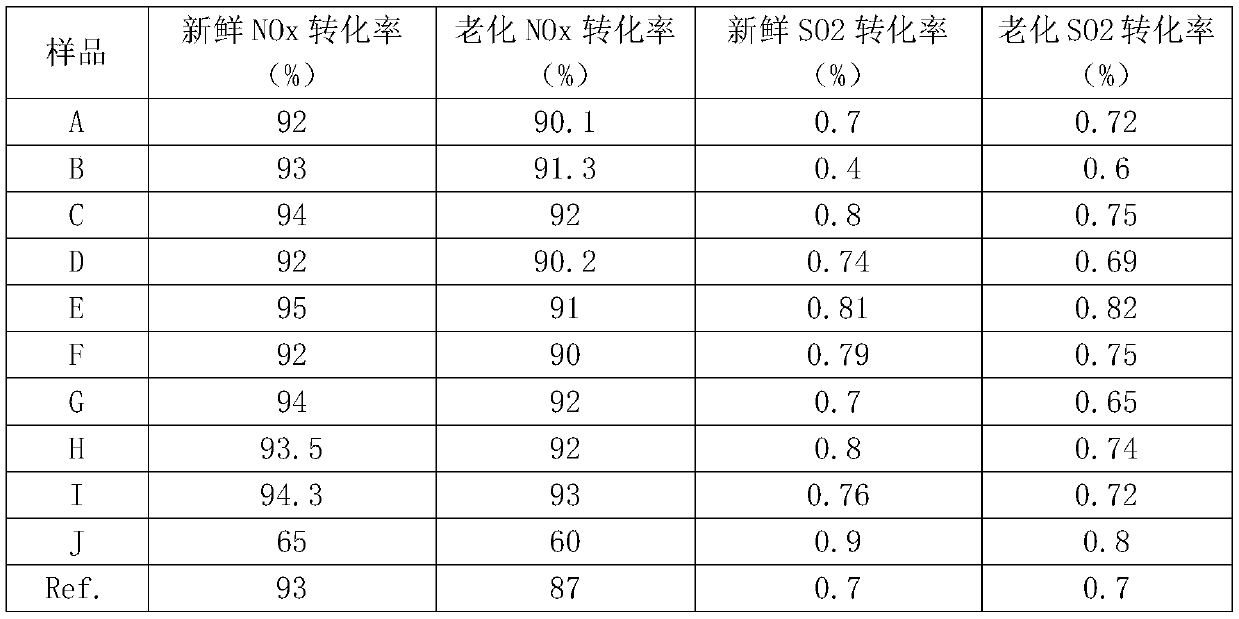

Examples

Embodiment 1

[0023] First, the waste vanadium-based SCR catalyst was cleaned and pulverized in a conventional manner to obtain a waste catalyst powder, and then 0.5 parts of ammonium thiosulfate solution dissolved in 5 parts of deionized water was added to 100 parts of the waste catalyst powder. Stir and mix for 1 hour, and dry to obtain the regenerated waste catalyst coarse powder; roast the dried waste catalyst regenerated coarse powder at 300°C for 2 hours, and then ball mill to the regenerated catalytic powder A with a particle size of D50=2μm.

Embodiment 2

[0025] First, the waste vanadium-based SCR catalyst is cleaned and pulverized in a conventional manner to obtain a waste catalyst powder, and then 1 part of citric acid solution dissolved in 6 parts of deionized water is added to 100 parts of the waste catalyst powder, and stirred and mixed at room temperature React for 1.5 hours and dry to obtain regenerated waste catalyst coarse powder; roast the dried waste catalyst regenerated coarse powder at 200°C for 4 hours, then ball mill to regenerated catalytic powder B with a particle size of D50=4.2 μm.

Embodiment 3

[0027] First, the waste vanadium-based SCR catalyst is cleaned and pulverized in a conventional manner to obtain a waste catalyst powder, and then 2 parts of malonic acid solution dissolved in 8 parts of deionized water is added to 100 parts of the waste catalyst powder, and stirred at room temperature Mix and react for 2 hours, and dry to obtain regenerated waste catalyst coarse powder; roast the dried waste catalyst regenerated coarse powder at 250°C for 3.5 hours, then ball mill to regenerated catalytic powder C with a particle size of D50=5.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com