Glass powder with strong impact resistance and adjustable expansion coefficient and preparation method thereof

A technology of expansion coefficient and impact resistance, which is applied in the field of glass powder and its preparation, can solve problems such as poor impact resistance, and achieve the effects of low cost, good impact resistance, and adjustable expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

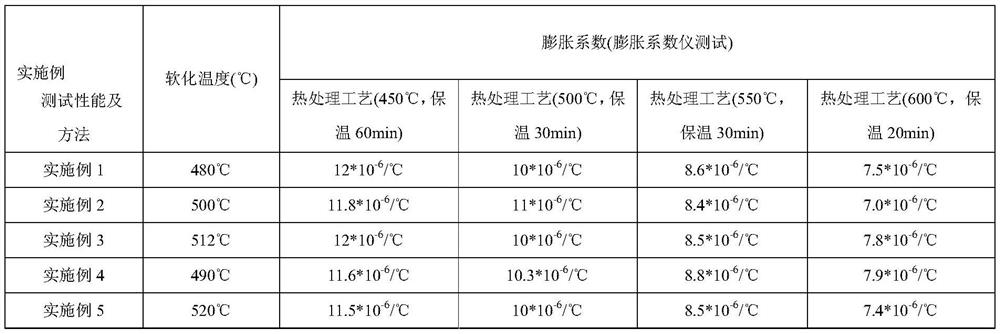

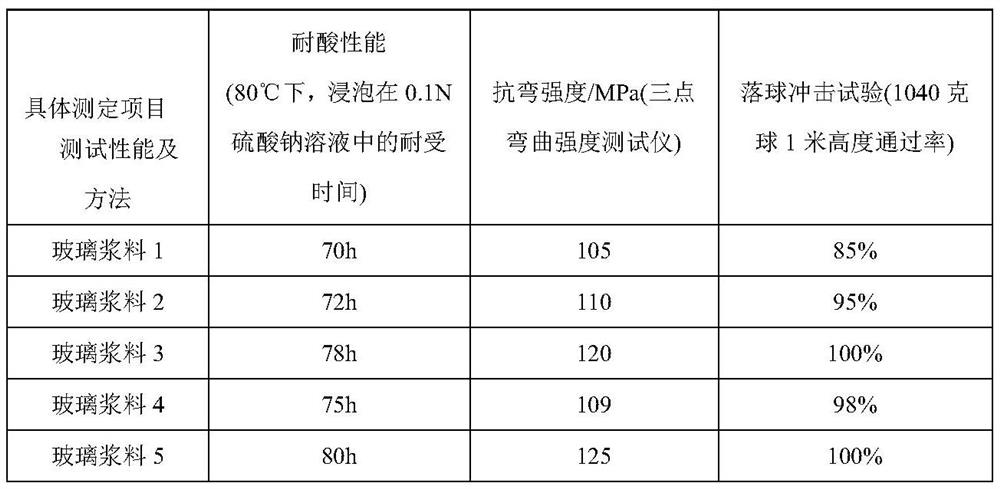

Examples

Embodiment 1

[0017] (1) Weigh SiO by parts by weight 2 : 30 parts, Bi 2 o 3 : 40 parts, ZnO: 5 parts, BaO: 1 part, Al 2 o 3 : 6 parts, SnO 2 : 3 parts, Na 2 O: 2 copies, B 2 o 3 : 5 parts, Li 2 O: 3 parts, TiO 2 : 5 parts of each raw material and fully mixing it to obtain a mixture;

[0018] (2) Put the mixed material obtained in step (1) into a crucible and place it in a high-temperature kiln for melting, the melting temperature is 1000° C., and the above-mentioned melting time is 50 minutes to obtain molten glass;

[0019] (3) carrying out water quenching cooling to the molten glass obtained in step (2) to obtain cullet;

[0020] (4) transfer the cullet block obtained in step (3) to a ball mill and carry out ball milling to obtain glass powder;

[0021] (5) Dry the glass powder material obtained in step (4) in a drying oven, the drying temperature is 100°C, and the drying time is 2h, and after sieving with a 250-mesh sieve, dry glass powder, glass The particle size of the pow...

Embodiment 2

[0023] (1) Weigh SiO by parts by weight 2 : 40 parts, Bi 2 o 3 : 30 parts, ZnO: 8 parts, BaO: 2 parts, Al 2 o 3 : 0 parts, SnO 2 : 1 part, Na 2 O: 4 copies, B 2 o 3 : 10 parts, Li 2 O: 4 parts, TiO 2 : 1 part of each raw material and fully mixing it to obtain a mixture;

[0024] (2) Put the mixture obtained in step (1) into a crucible and place it in a high-temperature kiln for melting, the melting temperature is 1080° C., and the above-mentioned melting time is 40 minutes to obtain molten glass;

[0025] (3) carrying out water quenching cooling to the molten glass obtained in step (2) to obtain cullet;

[0026] (4) transfer the cullet block obtained in step (3) to a ball mill and carry out ball milling to obtain glass powder;

[0027] (5) Dry the glass powder material obtained in step (4) in a drying oven, the drying temperature is 120°C, and the drying time is 1h, and after sieving with a 250-mesh sieve, dry glass powder, glass The particle size of the powder sat...

Embodiment 3

[0029] (1) Weigh SiO by parts by weight 2 : 45 parts, Bi 2 o 3 : 20 parts, ZnO: 7 parts, BaO: 2 parts, Al 2 o 3 : 2 parts, SnO 2 : 0 parts, Na 2 O: 1 copy, B 2 o 3 : 15 parts, Li 2 O: 4 parts, TiO 2 : 4 parts of each raw material are fully mixed to obtain a mixture;

[0030] (2) Put the mixture obtained in step (1) into a crucible and place it in a high-temperature kiln for melting, the melting temperature is 1200° C., and the above-mentioned melting time is 40 minutes to obtain molten glass;

[0031] (3) carrying out water quenching cooling to the molten glass obtained in step (2) to obtain cullet;

[0032] (4) transfer the cullet block obtained in step (3) to a ball mill and carry out ball milling to obtain glass powder;

[0033](5) Dry the glass powder material obtained in step (4) in a drying oven, the drying temperature is 140°C, and the drying time is 1h, and after sieving with a 250-mesh sieve, dry glass powder, glass The particle size of the powder satisfie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com