Calcium copper titanate ceramic reduction-oxidizing atmosphere co-sintering method

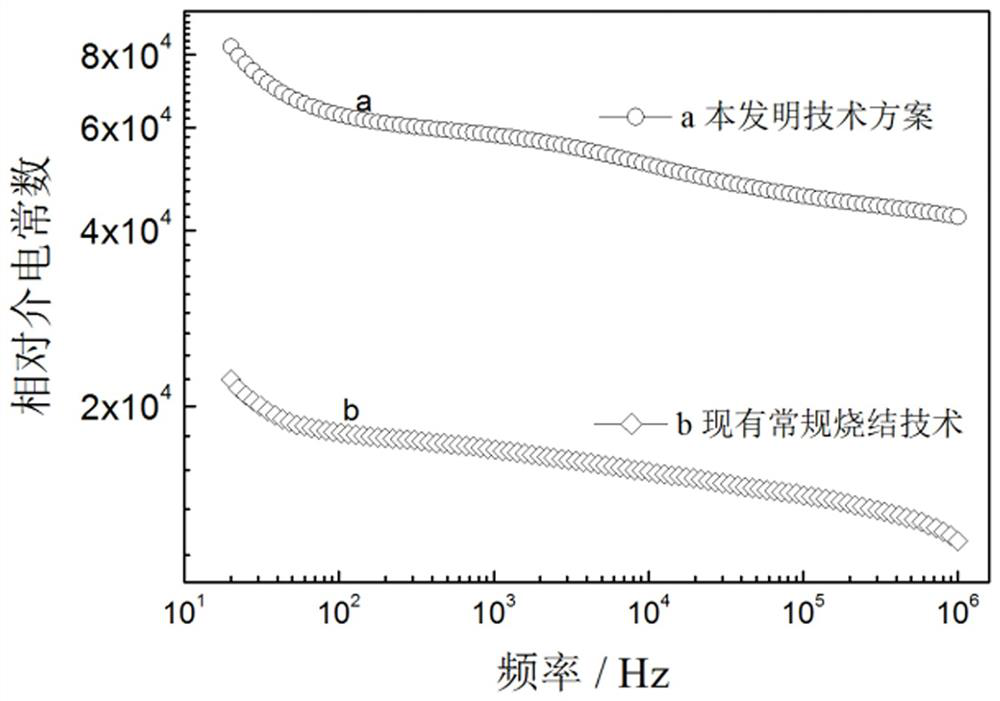

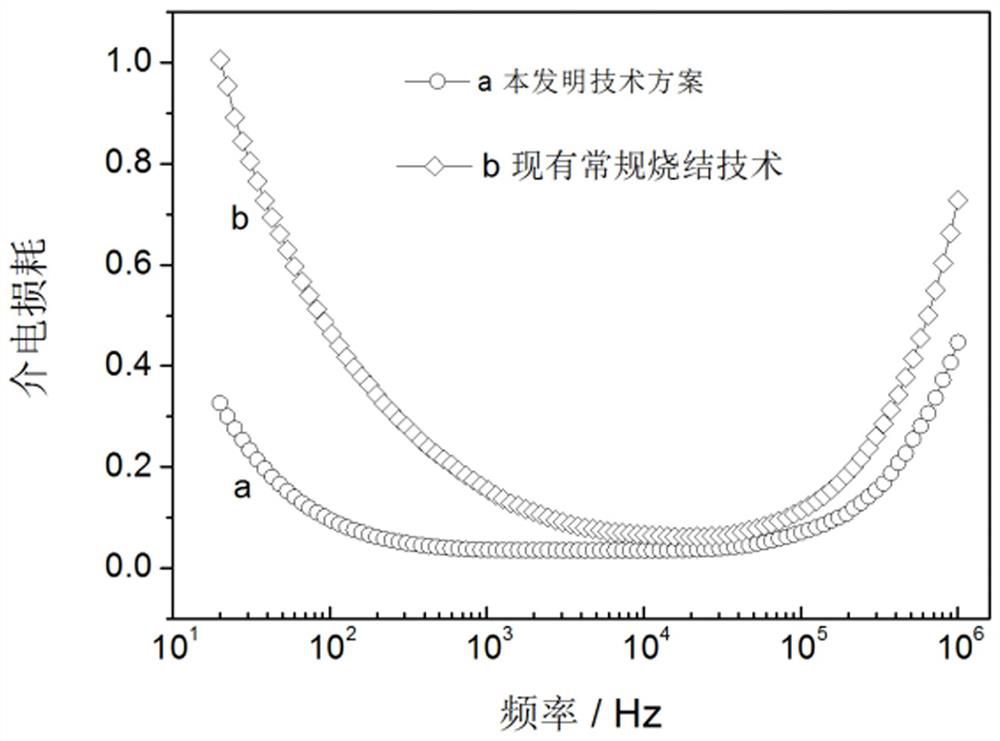

An oxidizing atmosphere, copper calcium titanate technology, applied in the field of dielectric materials, can solve the problems of decreased dielectric constant, difficult to meet the requirements of device applications, and insignificant reduction of dielectric loss, and achieve simple operation, improved dielectric properties, The Effect of Simultaneous Optimization of Dielectric Constant and Dielectric Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

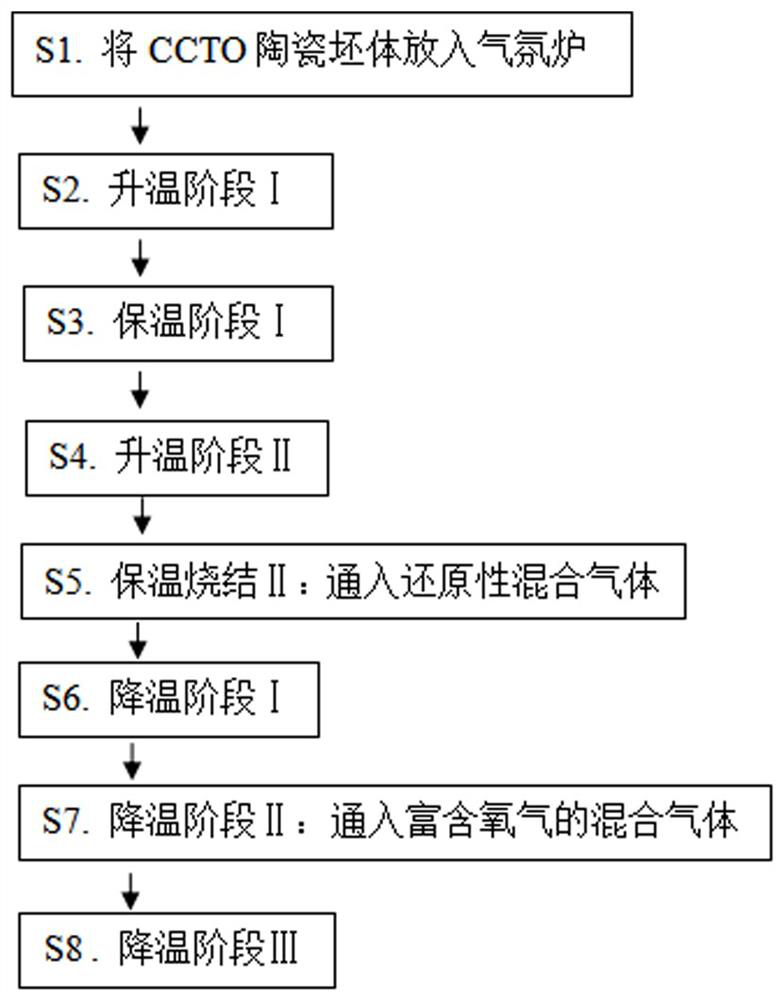

Method used

Image

Examples

Embodiment 2

[0051] Another preferred embodiment 2 of the present invention, concrete implementation steps are as follows:

[0052] S1 Put the pressed CCTO ceramic body into the atmosphere furnace. In this embodiment 2, a tubular atmosphere furnace with an inner diameter of 20 cm is used as the atmosphere furnace, and a disc-shaped CCTO green body is selected for sintering, wherein the diameter of the disc-shaped ceramic green body is 10 mm, and the thickness is about 2 mm; During the implementation of this step, the CCTO ceramic body is firstly placed on a corundum backing plate, and then placed in an atmosphere furnace.

[0053] S2 implements the heating phase I. During the implementation of this step, turn on the gas circuit switch connecting the atmosphere furnace to the outside atmosphere, so that the atmosphere furnace is heated from room temperature to 600°C in the air atmosphere, and the temperature rise rate of the atmosphere furnace is 5-8°C / min during the heating process.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com