Method for preparing hollow cobalt-nickel alloy/porous carbon composite wave-absorbing material

A composite wave-absorbing material, cobalt-nickel alloy technology, applied in carbon preparation/purification, magnetic field/electric field shielding, electrical components, etc., can solve the problems of single electromagnetic wave attenuation mechanism, easy oxidation of microwave absorbing materials, complex preparation methods, etc. Achieve multiple electromagnetic wave attenuation mechanisms, excellent lightweight microwave absorption performance, and easy follow-up processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The specific implementation steps of the present invention are as follows:

[0022] Step 1: Dissolve 0.48 g of cobalt chloride hexahydrate, 0.48 g of nickel chloride hexahydrate and 1.0 g of polyvinylpyrrolidone in 36 mL of ethylene glycol under stirring at room temperature. Then, add 4 mL of 80% hydrazine hydrate to the above solution. Finally, the mixed solution was transferred into an autoclave and kept at 180 °C for 6 h. The reaction product was washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 60°C to obtain a hollow CoNi alloy;

[0023] Step 2: Disperse 0.2 g of the hollow CoNi alloy prepared in Step 1 in a mixed solution of 50 mL of deionized water, 20 mL of absolute ethanol and 1 mL of ammonia water under ultrasonic vibration. Subsequently, 0.2 g of resorcinol and 0.28 mL of 37% formaldehyde were added to the above solution. The reaction was stirred mechanically at room temperature for 24 h. The product was collected...

Embodiment 2

[0026] The difference between this example and Example 1 is that in step 3, the hollow CoNi@phenolic resin prepared in step 2 was heated from room temperature to 700°C for 2 hours under a nitrogen atmosphere and a heating rate of 2°C / min, and then calcined for 2 hours. Naturally cooled to room temperature under atmosphere. Others are the same as in Example 1.

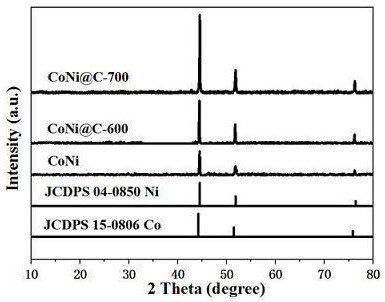

[0027] figure 1 For the X-ray diffraction pattern, CoNi, CoNi@C-600 and CoNi@C-700 have three sharp peaks at 44.4°, 51.7° and 76.3°, corresponding to (111), ( 200) and (220) crystal faces. Each diffraction peak is a single peak, indicating that the sample is not a mixture of elements cobalt and nickel, but exists in the form of an alloy.

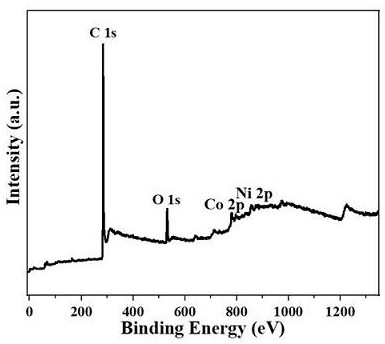

[0028] figure 2 For the total spectrogram of the XPS of the CoNi@porous carbon prepared in embodiment 2, from figure 2 It can be seen that CoNi@C-700 contains four elements: C, O, Co, and Ni.

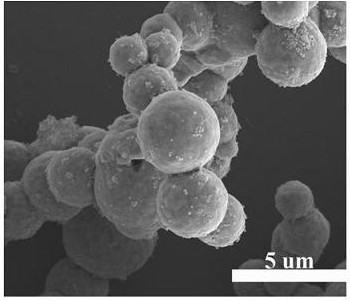

[0029] image 3 The SEM picture of the CoNi@porous carbon prepared in step 3 of Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com