High-nitrogen 316LN stainless steel welding wire and production method thereof

A production method, stainless steel technology, applied in the field of metallurgy, can solve the problems of nitrogen overflow, limited nitrogen increase, prolong smelting cycle, etc., achieve the effect of increasing tensile strength and yield strength, reducing production cycle, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

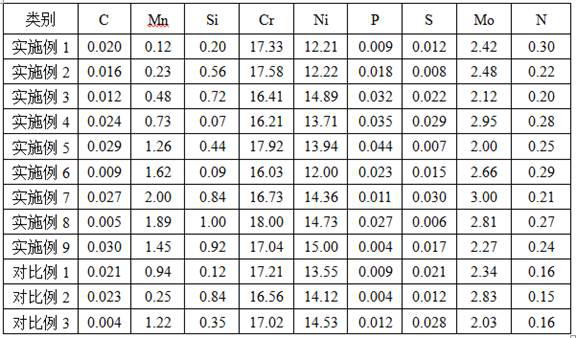

[0027] The chemical composition and mass percentage of the high-nitrogen 316LN stainless steel welding wire in this example are shown in Table 1, and its mechanical properties are shown in Table 2.

[0028] The production method of high-nitrogen 316LN stainless steel welding wire in this embodiment includes smelting, electroslag remelting, homogenization treatment, forging, wire rod rolling, pickling, annealing and drawing processes, and nitrogen-increasing treatment is carried out during the annealing and drawing process . Each step is described as follows:

[0029] (1) Smelting process: Smelt 400kg of steel billet without nitrogen addition in a 1t non-vacuum induction furnace, and cast a round ingot with a diameter of 220mm;

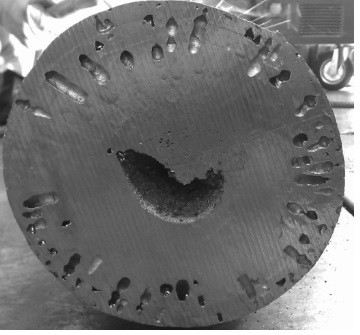

[0030] (2) Electroslag remelting process: Carry out electroslag remelting to round ingots. This process is protected by argon gas. The gas flow rate is 150L / min. In the stable period, the melting rate is controlled at 4-5kg / min, and the diameter is 30...

Embodiment 2

[0036] The chemical composition and mass percentage of the high-nitrogen 316LN stainless steel welding wire in this example are shown in Table 1, and its mechanical properties are shown in Table 2.

[0037] The production method of high-nitrogen 316LN stainless steel welding wire in this embodiment includes smelting, electroslag remelting, homogenization treatment, forging, wire rod rolling, pickling, annealing and drawing processes, and nitrogen-increasing treatment is carried out during the annealing and drawing process . Each step is described as follows:

[0038] (1) Smelting process: Smelt 230kg of steel billet without adding nitrogen through a 250kg non-vacuum induction furnace, and cast a round ingot with a diameter of 220mm;

[0039] (2) Electroslag remelting process: Carry out electroslag remelting to round ingots. This process is protected by argon gas. The gas flow rate is 150L / min. In the stable period, the melting rate is controlled at 4-5kg / min, and the diameter...

Embodiment 3

[0045] The chemical composition and mass percentage of the high-nitrogen 316LN stainless steel welding wire in this example are shown in Table 1, and its mechanical properties are shown in Table 2.

[0046] The production method of high-nitrogen 316LN stainless steel welding wire in this embodiment includes smelting, electroslag remelting, homogenization treatment, forging, wire rod rolling, pickling, annealing and drawing processes, and nitrogen-increasing treatment is carried out during the annealing and drawing process . Each step is described as follows:

[0047] (1) Smelting process: Smelt 210kg of steel billet without adding nitrogen through a 250kg non-vacuum induction furnace, and cast a round ingot with a diameter of 220mm;

[0048] (2) Electroslag remelting process: Carry out electroslag remelting to round ingots, which is protected by argon gas, the gas flow rate is 155L / min, the melting speed is controlled at 4-5kg / min in the stable period, and the diameter is 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com