A kind of photocuring 3D printing hierarchical porous ceramic material and preparation method thereof

A technology of 3D printing and ceramic materials, which is applied in the field of porous ceramic materials, can solve the problems that the distribution of pores cannot be realized, and the pore size of multi-level porous ceramic materials can not be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Based on the deficiencies of the prior art, the present invention provides a method for preparing a photocured 3D printed hierarchically porous ceramic material. In parts by weight, the raw material formula used in the preparation method is as follows: 10-15 parts by weight of photosensitive resin; diluent 20-25 parts by weight; ceramic powder 35-50 parts by weight; hierarchical pore accelerator 1-15 parts by weight; surfactant 1-8 parts by weight; dispersant 1-10 parts by weight; curing agent 5-9 parts by weight ; Ultraviolet light absorption regulator 1-5 parts by weight.

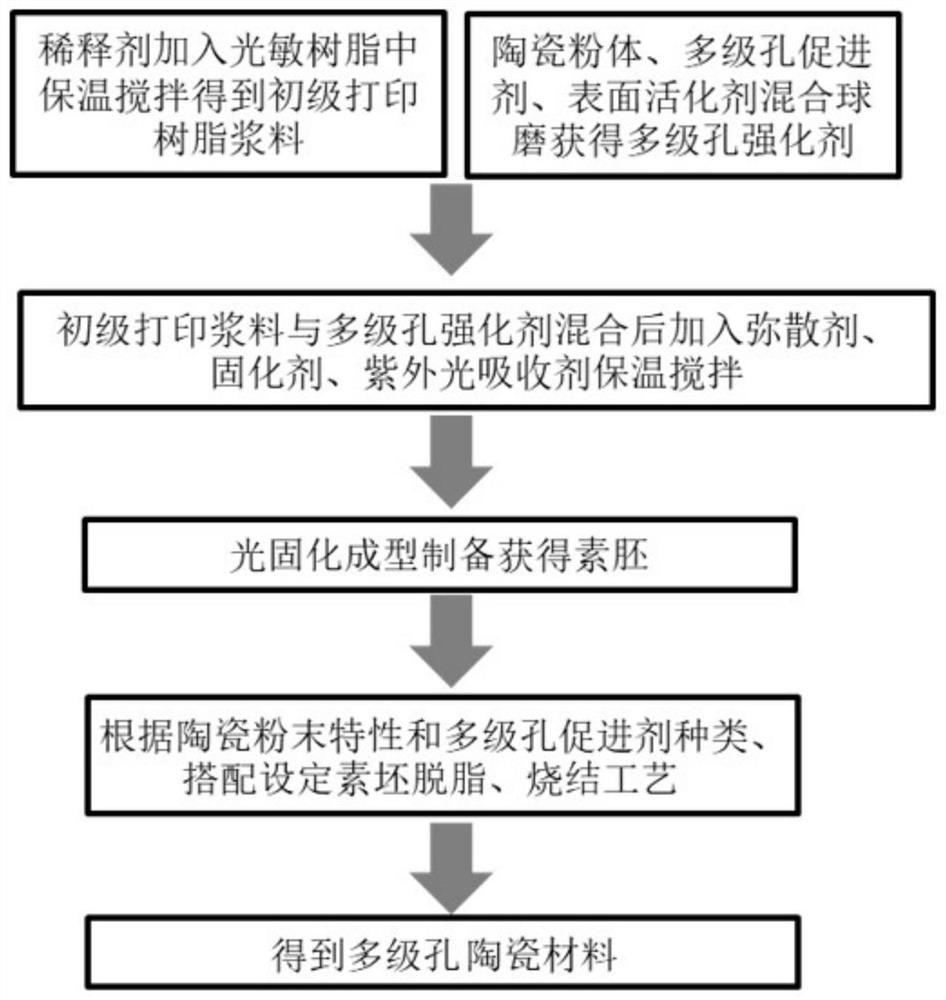

[0056] figure 1 It is a process flow chart of the preparation method of the light-cured 3D printing multi-level porous ceramic material provided by the embodiment of the present invention, see figure 1 , mainly including the following steps:

[0057] Steps for preparing the primary printing resin slurry: adding the diluent to the photosensitive resin and performing heat preservation and stirring ...

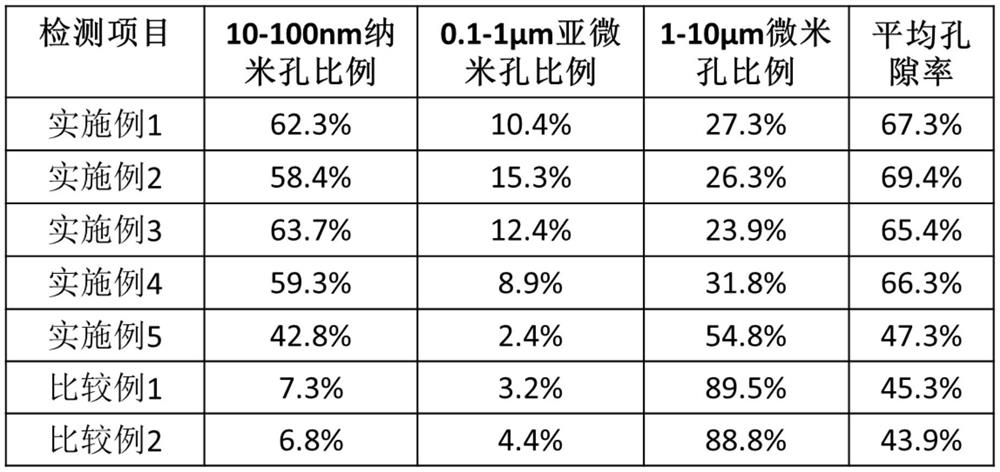

Embodiment 1

[0085]In this example, a light-cured 3D printing hierarchical porous ceramic material is prepared. The raw material formula used is as follows: 15 parts by weight of photosensitive resin, 20 parts by weight of diluent, 35 parts by weight of ceramic powder, 15 parts by weight of hierarchical porous accelerator, 1 part by weight of a surfactant, 4 parts by weight of a dispersant, 5 parts by weight of a curing agent, and 5 parts by weight of an ultraviolet light absorption regulator. Wherein, the photosensitive resin is a resin obtained by mixing 1,6-hexanediol diacrylate and tripropylene glycol diacrylate at a ratio of 7:1. The diluent is deionized water. Ceramic powder is Al 2 o 3 . The hierarchical pore promoter is a mixture of carbon fiber and indium at a ratio of 7:3. The surfactant is γ-methacryloxypropyltrimethoxysilane coupling agent. The dispersant is polyvinylpyrrolidone. The curing agent is 2,4,6-trimethylbenzoyl-diphenylphosphine oxide. The ultraviolet light ab...

Embodiment 2

[0098] In this example, a light-cured 3D printing hierarchical porous ceramic material is prepared. The raw material formula used is as follows: 10 parts by weight of photosensitive resin, 25 parts by weight of diluent, 40 parts by weight of ceramic powder, 10 parts by weight of hierarchical porous accelerator, 4 parts by weight of a surfactant, 4 parts by weight of a dispersant, 6 parts by weight of a curing agent, and 1 part by weight of an ultraviolet light absorption regulator. Wherein, the photosensitive resin is a 6:5 mixed resin of trimethylolpropane triacrylate and trimethylolpropane tetraacrylate. The diluent is silica sol. Ceramic powder is SiO 2 、Al 2 o 3 , ZrO 2 Mixed powders were obtained in a ratio of 7:1:2. The hierarchical pore promoter is a mixture of Ti powder, ammonium salt and lead in a ratio of 4:3:3. The surfactant is a methacryloxysilane coupling agent. The dispersant is sodium polyacrylate. The curing agent is 2-hydroxy-2-methyl-1 phenylacetone-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com