Flexible conductive fiber with sheath-core structure and preparation method thereof

A conductive fiber, core-sheath technology, applied in the field of flexible conductive fibers and their preparation, can solve the problems of difficulty in reducing the inner layer graphene oxide, loss of graphene conductivity, insufficient reduction, etc., and achieve good dispersibility and spinnability. , Improve the electrical conductivity and enhance the effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Prepare large sheets of GO by the improved Hummers method, and then remove excess acid and unexfoliated expanded graphite by centrifugation to obtain GO aqueous solution; then centrifuge at 12000rad / min for 30min to obtain GO with a concentration of 20mg / ml aqueous solution;

[0038] (2) Take 20ml of GO solution with the same solubility, then add 100mg of GNPs, stir and ultrasonically disperse for 15min, and further mix in AR-100 stirring and defoaming machine for 3min, degassing for 1min to obtain a uniformly mixed suspension as the core layer spinning solution;

[0039] (3) Weigh Kevlar 49 and KOH 6.73g and add them to 300ml DMSO, after sealing, stir and dissolve at room temperature for two weeks, then further centrifuge at 8000rad / min for 5 minutes to remove undissolved KOH in the suspension, and prepare The ANF / DMSO solution of 2wt% solubility, as sheath layer spinning solution;

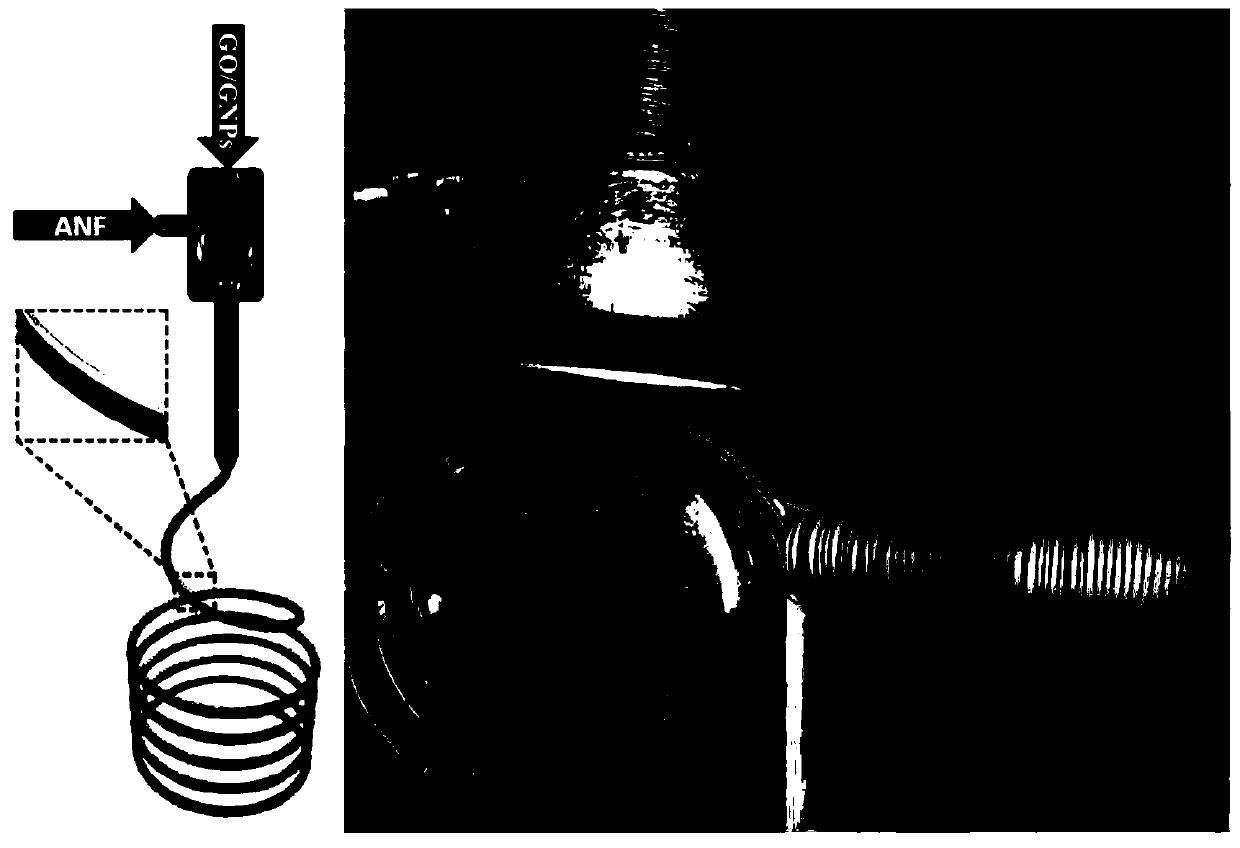

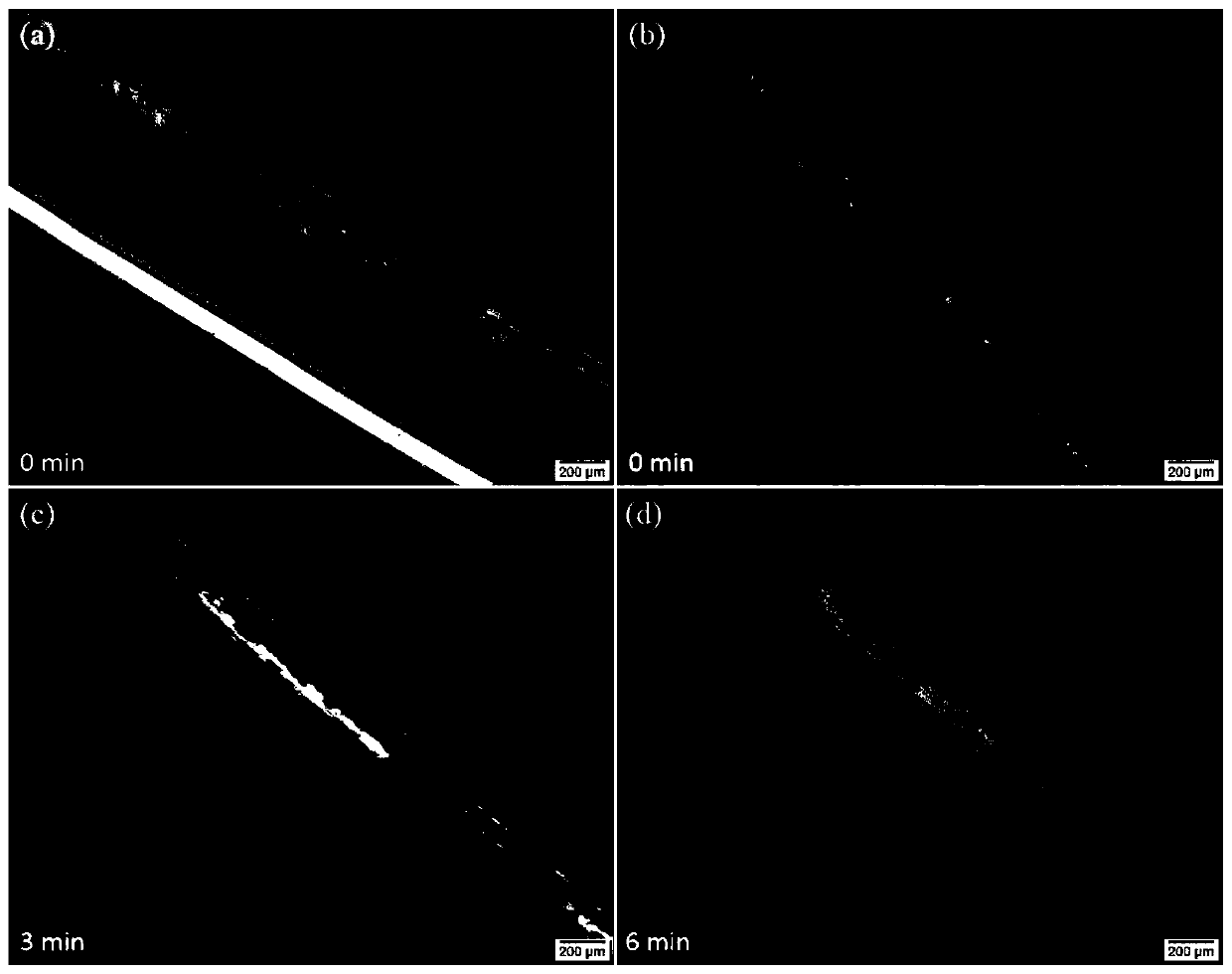

[0040] (4) Take an appropriate amount of step (2) and (3) core layer spinning so...

Embodiment 2

[0043] (1) Prepare large sheets of GO by the improved Hummers method, and then remove excess acid and unexfoliated expanded graphite by centrifugation to obtain GO aqueous solution; then centrifuge at 12000rad / min for 30min to obtain GO with a concentration of 20mg / ml solution;

[0044] (2) Take 20ml of GO solution with the same solubility, then add 200mg of GNPs, stir and ultrasonically disperse for 15min, and further mix in AR-100 stirring defoaming machine for 3min, degassing for 1min to obtain a uniformly mixed suspension as the core layer spinning solution;

[0045] (3) Weigh Kevlar 49 and KOH 6.73g and add them to 300ml DMSO, after sealing, stir and dissolve at room temperature for two weeks, then further centrifuge at 8000rad / min for 5 minutes to remove undissolved KOH in the suspension, and prepare The ANF / DMSO solution of 2wt% solubility, as sheath layer spinning solution;

[0046] (4) Take an appropriate amount of step (2) and (3) core layer spinning solution and s...

Embodiment 3

[0057] (1) Prepare large sheets of GO by the improved Hummers method, and then remove excess acid and unexfoliated expanded graphite by centrifugation to obtain GO aqueous solution; then centrifuge at 10000rad / min for 30min to obtain GO with a concentration of 15mg / ml solution;

[0058] (2) Take 20ml of GO solution with the same solubility, then add 100mg of GNPs, stir and ultrasonically disperse for 15min, and further mix in AR-100 stirring and defoaming machine for 3min, degassing for 1min to obtain a uniformly mixed suspension as the core layer spinning solution;

[0059] (3) Weigh Kevlar 49 and KOH 6.73g and add them to 300ml DMSO, after sealing, stir and dissolve at room temperature for two weeks, then further centrifuge at 8000rad / min for 5 minutes to remove undissolved KOH in the suspension, and prepare The ANF / DMSO solution of 2wt% solubility, as sheath layer spinning solution;

[0060] (4) Take an appropriate amount of step (2) and (3) core layer spinning solution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com