A kind of silicon-based tray for mocvd equipment and preparation method

A tray and silicon-based technology, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve problems such as cracking and falling off of SiC coating, easy oxidation of graphite material, etc., to relieve thermal expansion and reduce peak stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a silicon-based tray for MOCVD equipment according to a specific embodiment of the present invention includes the following steps:

[0033] (1) Deposit a pyrolytic carbon transition layer on the surface of the Si substrate by chemical vapor deposition. Preferably, the deposition conditions of the pyrolytic carbon layer are as follows: methane is used as the carbon source material, argon is used as the diluent gas, and the deposition temperature is 900-1200 ℃, deposition time: 1~20h;

[0034] (2) The temperature is then increased to 1200-1400° C. and kept for 1-2 hours to form a SiC interface layer;

[0035] (3) The temperature is then lowered to 1000-1300°C, and a SiC coating is deposited on the prepared pyrolytic carbon transition layer by chemical vapor deposition. Preferably, the deposition conditions of the SiC coating are as follows: methyltrichlorosilane is used as SiC The source material is argon as the diluent gas, hydrogen as the carrier...

Embodiment 1

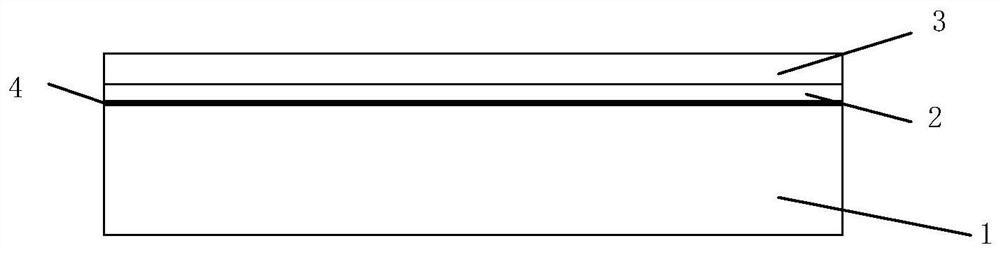

[0037] The silicon-based tray for MOCVD equipment in this embodiment is composed of a Si substrate 1, a pyrolytic carbon transition layer 2, a SiC coating 3, and a SiC interface layer 4 at the interface between the Si substrate 1 and the pyrolytic carbon layer 2, The base material of the tray is high-purity Si material, its purity is 99.9999%, the diameter is 120mm, there are 3 circular grooves on the surface, the groove depth is 1mm, there is a composite coating on the surface of the tray, and the innermost layer is a pyrolytic carbon transition layer 2, There is a layer of SiC interface layer 4 between the pyrolytic carbon transition layer 2 and the Si substrate 1 , and the outermost layer is a SiC coating layer 3 . The thickness of the tray is 3 mm, the thickness of the outermost SiC coating layer 3 is 100 μm, the thickness of the pyrolytic carbon transition layer 2 is 5 μm, and the thickness of the SiC interface layer 4 is 100 nm.

[0038] The preparation method of the sil...

Embodiment 2

[0043] The silicon-based tray for MOCVD equipment in this embodiment is composed of a Si substrate 1, a pyrolytic carbon transition layer 2, a SiC coating 3, and a SiC interface layer 4 at the interface between the Si substrate 1 and the pyrolytic carbon layer 2, The base material of the tray is high-purity Si material, its purity is 99.9999%, the diameter is 120mm, there are 3 circular grooves on the surface, the groove depth is 1mm, there is a composite coating on the surface of the tray, and the innermost layer is a pyrolytic carbon transition layer 2, There is a layer of SiC interface layer 4 between the pyrolytic carbon transition layer 2 and the Si substrate 1 , and the outermost layer is a SiC coating layer 3 . The thickness of the tray is 3 mm, the thickness of the outermost SiC coating layer 3 is 90 μm, the thickness of the pyrolytic carbon transition layer 2 is 6 μm, and the thickness of the SiC interface layer 4 is 80 nm.

[0044] The preparation method of the silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com