Nano-modified reinforced toughened antibacterial random copolymerized polypropylene special material and preparation method thereof

A technology of strengthening and toughening, random copolymerization, applied in the field of plastic materials, can solve the problems of polymer performance damage, adverse effects, difficult dispersion, etc., to achieve the effect of improving flame retardant performance, improving mechanical properties, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of nano-modified reinforced toughened antibacterial random copolymerized polypropylene special material comprises the following steps:

[0043] 1. Preparation of environment-friendly nano ammonium polyphosphate coated modified flame retardant:

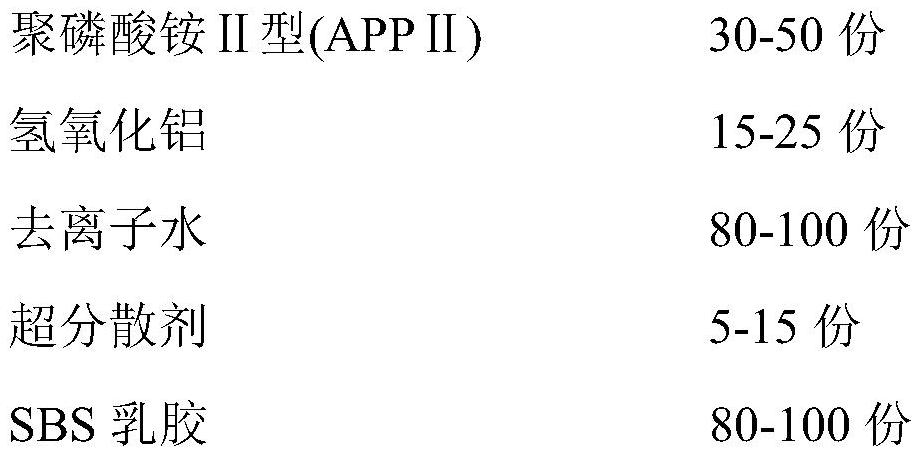

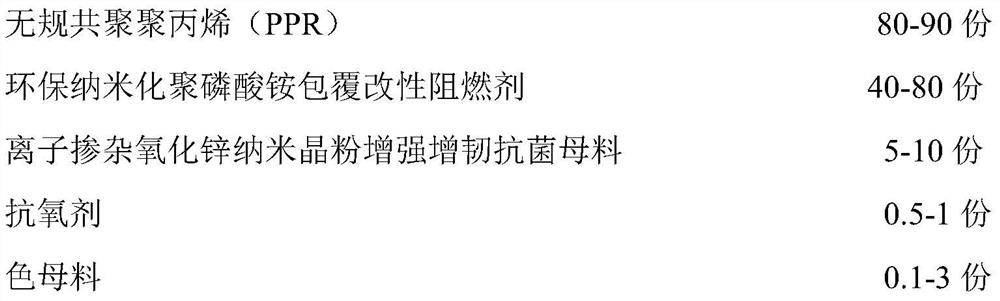

[0044] Formula (by mass ratio):

[0045]

[0046] 1) Mix ammonium polyphosphate, aluminum hydroxide, deionized water, and hyperdispersant according to a certain mass ratio of the formula, mix them at high speed on a high-speed emulsifier for 1 hour, and the speed of the high-speed emulsifier is 4000 rpm. The nano-dispersion grinder performs strong shear dispersion on the mixture, the speed is 5000 rpm, and the shear dispersion is 5 hours, so that the ammonium polyphosphate and aluminum hydroxide are depolymerized and dispersed into a nano-mixed suspension. The obtained nano-mixed suspension The particle content of inorganic nanomaterial particles with a particle size below 102nm accounts for more than ...

Embodiment 2

[0060] The preparation method of nano-modified reinforced toughened antibacterial random copolymerized polypropylene special material comprises the following steps:

[0061] 1. Preparation of environment-friendly nano ammonium polyphosphate coated modified flame retardant:

[0062] Formula (by mass parts):

[0063]

[0064] 1) Mix ammonium polyphosphate, aluminum hydroxide, deionized water, and hyperdispersant according to a certain mass ratio of the formula, and mix them on a high-speed emulsifier for 1.5 hours at a high speed. The speed of the high-speed emulsifier is 5000 rpm. The nano-dispersion grinder performs strong shear dispersion on the mixture, the speed is 8000 rpm, and the shear dispersion is 3 hours, so that the ammonium polyphosphate and aluminum hydroxide are depolymerized and dispersed into a nano-mixed suspension. The obtained nano-mixed suspension The particle content of inorganic nanomaterial particles with a particle size below 100nm accounts for more ...

Embodiment 3

[0079] The preparation method of nano-modified reinforced toughened antibacterial random copolymerized polypropylene special material comprises the following steps:

[0080] 1. Preparation of environment-friendly nano ammonium polyphosphate coated modified flame retardant:

[0081] Formula (by mass ratio):

[0082]

[0083] 1) Mix ammonium polyphosphate II, aluminum hydroxide, deionized water, and hyperdispersant (TG-F063) according to a certain mass ratio of the formula, and perform high-speed mixing on a high-speed emulsifier for 2 hours, and the speed of the high-speed emulsifier is 6000 rpm / min, and then through the high-speed nano-dispersion grinder, the mixture is strongly sheared and dispersed at a speed of 10,000 rpm, and sheared and dispersed for 2 hours, so that the ammonium polyphosphate and aluminum hydroxide are depolymerized and dispersed into a nano-mixed suspension. In the obtained nano-mixed suspension, the particle content of inorganic nano-material part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com