Bioactive 3D printing ceramic and preparation method thereof

A 3D printing and bioactive technology, which is applied in the field of bioactive 3D printing ceramics and its preparation, can solve the problems of no biological activity and poor degradation performance, and achieve the effect of increasing biological activity, good degradation performance and high product precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

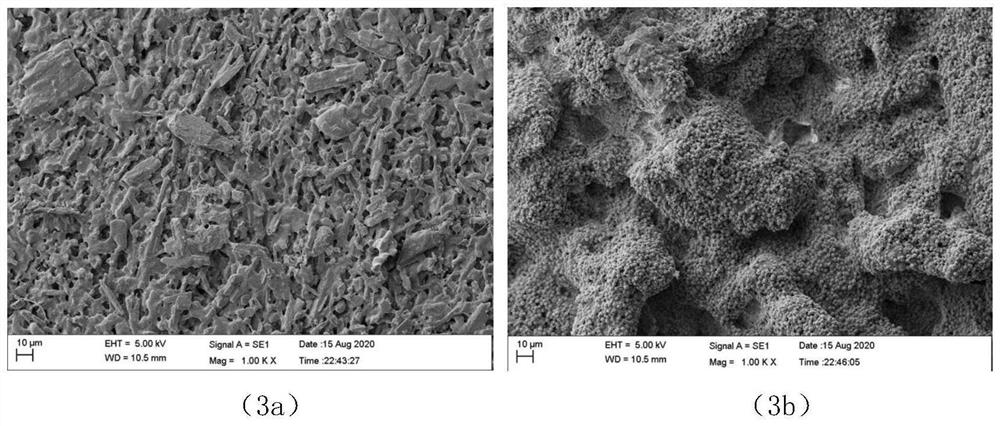

Image

Examples

Embodiment 1

[0029] (1) Preparation of ceramic slurry: Add 70 parts of calcium silicate powder to 30 parts of photosensitive resin premix, stir under normal pressure, so that each component is dispersed evenly, and ceramic slurry is obtained;

[0030] (2) Printing and forming: the slurry is poured into the barrel of the stereolithography printer, the STL format model is imported into the stereolithography printer, and the printing parameters of the stereolithography are adjusted so that the ceramic slurry is stacked and formed layer by layer. Solidifying the slurry to obtain a ceramic stent green body;

[0031] (3) Place the ceramic support green body in a muffle furnace for degreasing and sintering. The degreasing sintering system is set as follows: 30-300°C heating rate is 5°C / min, heat preservation for 2 hours, 300-600°C heating rate is 5°C / min , heat preservation for 2 hours, 600-1100 ° C heating rate of 3 ° C / min, heat preservation for 2 hours, 1100 ° C ~ room temperature natural co...

Embodiment 2

[0034] (1) Preparation of ceramic slurry: Add 70 parts of calcium silicate powder to 30 parts of photosensitive resin premix, stir under normal pressure, so that each component is dispersed evenly, and ceramic slurry is obtained;

[0035] (2) Printing and forming: the slurry is poured into the barrel of the stereolithography printer, the STL format model is imported into the stereolithography printer, and the printing parameters of the stereolithography are adjusted so that the ceramic slurry is stacked and formed layer by layer. Solidifying the slurry to obtain a ceramic stent green body;

[0036] (3) Place the ceramic support green body in a muffle furnace for degreasing and sintering. The degreasing sintering system is set as follows: 30-300°C heating rate is 5°C / min, heat preservation for 2 hours, 300-600°C heating rate is 5°C / min , heat preservation for 2 hours, 600-1200 ° C heating rate of 3 ° C / min, heat preservation for 2 hours, 1200 ° C ~ room temperature natural co...

Embodiment 3

[0039] (1) Preparation of ceramic slurry: Add 70 parts of calcium silicate powder to 30 parts of photosensitive resin premix, stir under normal pressure, so that each component is dispersed evenly, and ceramic slurry is obtained;

[0040] (2) Printing and forming: the slurry is poured into the barrel of the stereolithography printer, the STL format model is imported into the stereolithography printer, and the printing parameters of the stereolithography are adjusted so that the ceramic slurry is stacked and formed layer by layer. Solidifying the slurry to obtain a ceramic stent green body;

[0041] (3) Place the ceramic support green body in a muffle furnace for degreasing and sintering. The degreasing sintering system is set as follows: 30-300°C heating rate is 5°C / min, heat preservation for 2 hours, 300-600°C heating rate is 5°C / min , heat preservation for 2 hours, 600-1100 ° C heating rate of 3 ° C / min, heat preservation for 2 hours, 1100 ° C ~ room temperature natural co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com