Autocatalytic resin oligomer based on DCPD phenol structure, condensate and preparation method

A technology of self-catalyzed resins and oligomers, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid nitriles, etc., can solve the problems of unreachable and limited application range, achieve wide processing window and simple process Controllable, low reaction temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

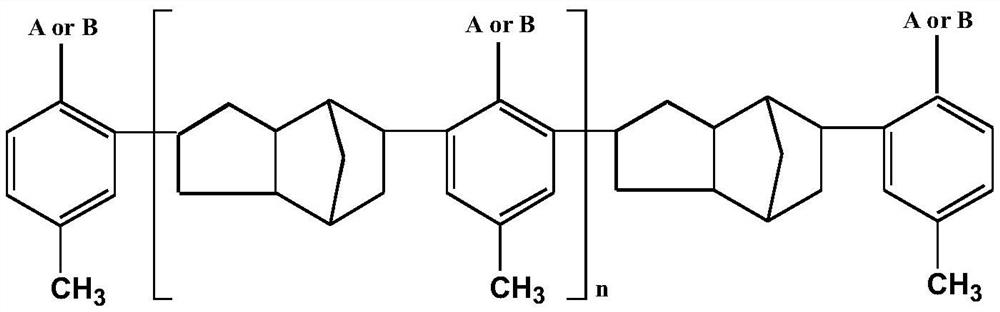

[0033] The preparation method of the self-catalyzed resin oligomer based on DCPD phenol structure specifically comprises the following steps:

[0034] 1) Mix DCPD phenol, cyano monomer, and catalyst, and react in a solvent. The reaction is carried out under the protection of an inert atmosphere, such as: nitrogen protection or argon protection

[0035] The catalyst is an organic base or an inorganic base, such as one or more of anhydrous potassium carbonate, anhydrous sodium carbonate, potassium hydroxide, sodium hydroxide, and sodium bicarbonate.

[0036] The solvent is a polar solvent, such as: one or more of NMP (N-methylpyrrolidone), DMF (N,N-dimethylformamide), DMSO (dimethyl sulfoxide), acetonitrile, preferably one of a kind.

[0037] The reaction temperature is 70-150° C., preferably 80-90° C.; the reaction time is controlled within 3-6 hours, preferably 4-5 hours.

[0038] Wherein, the molar ratio of DCPD phenol: cyano monomer is 1:(1.7-2.6), preferably 1:1.8. The c...

Embodiment 1

[0042] Add 30g (0.06mol) of DCPD phenol resin, 19g (0.11mol) of 4-nitrophthalonitrile, 30g (0.22mol) of anhydrous potassium carbonate, and 150ml of DMF into a three-necked flask, and heat it to 80°C under the protection of nitrogen to react 4 hours. The reaction solution was filtered to remove the catalyst, and part of the solvent was recovered from the filtrate under reduced pressure.

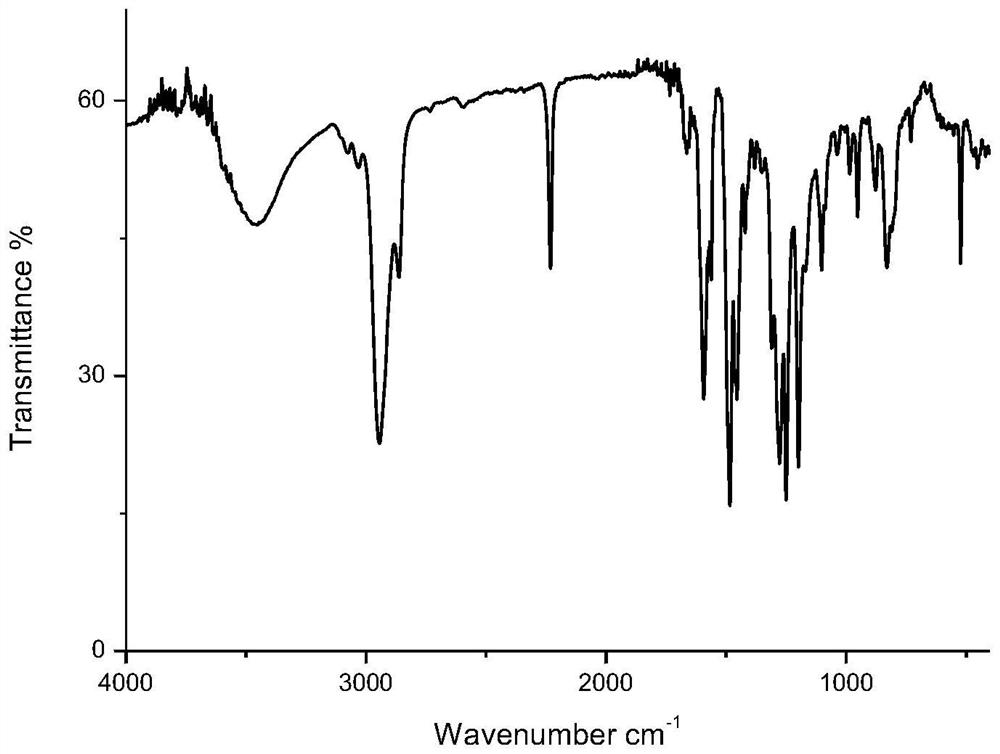

[0043] The filtrate is poured into 5wt% hydrochloric acid solution for sedimentation, filtered, stirred and washed with deionized water for 2 to 3 times until the filtrate is neutral, and the filter cake is vacuum-dried to obtain an autocatalyzed resin oligomer, see figure 1 .

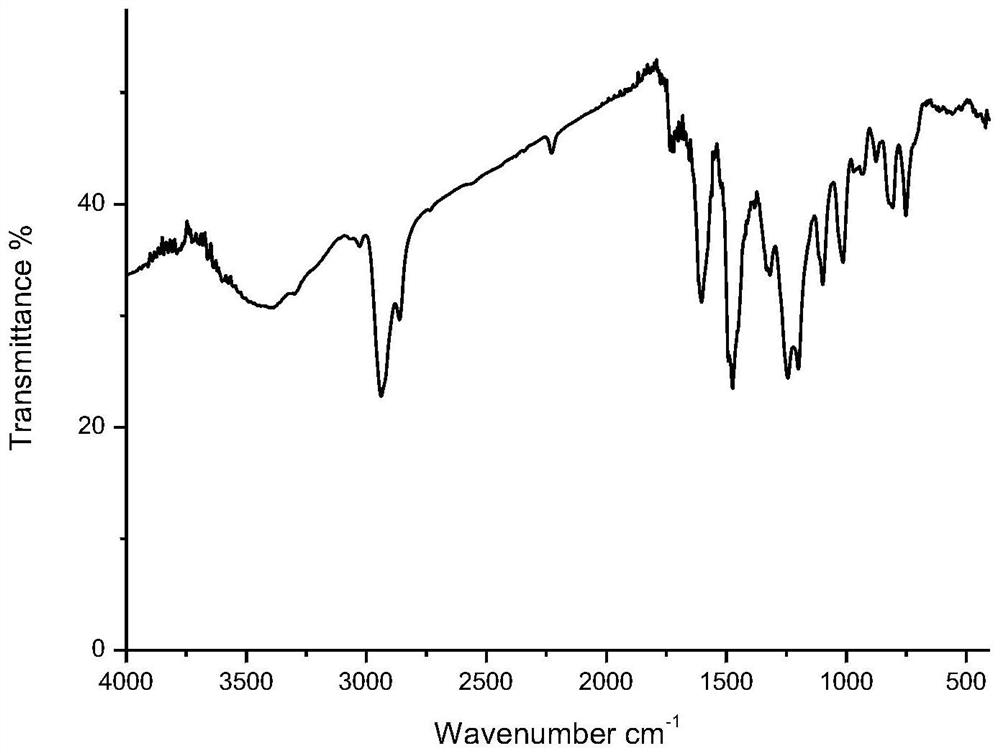

[0044] The resulting oligomer was pre-cured at 250°C for 4 hours and cured at 315°C for 2 hours to obtain a cured self-catalyzed resin, see figure 2 .

Embodiment 2

[0046] Add 30g (0.06mol) of DCPD phenol resin, 21g (0.12mol) of 4-nitrophthalonitrile, 40g (0.29mol) of anhydrous potassium carbonate, and 170ml of DMF into a three-necked flask, and heat it to 80°C under the protection of nitrogen to react 4 hours. The reaction solution was filtered to remove the catalyst, and part of the solvent was recovered from the filtrate under reduced pressure.

[0047] The filtrate is poured into 3 wt% hydrochloric acid solution for sedimentation, filtered, stirred and washed with deionized water for 2 to 3 times until the filtrate is neutral, and the filter cake is vacuum-dried to obtain an autocatalyzed resin oligomer.

[0048] The obtained oligomer was pre-cured at 250° C. for 4 hours and cured at 315° C. for 2 hours to obtain a cured self-catalyzed resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com