A kind of nattokinase sustained-release microspheres and preparation method thereof

A technology of nattokinase and slow-release microspheres, which is applied in the direction of biochemical equipment and methods, enzymes, peptidases, etc., can solve the problems of low effective rate, achieve enhanced stability, enhanced sustained release, and maintain thrombolytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

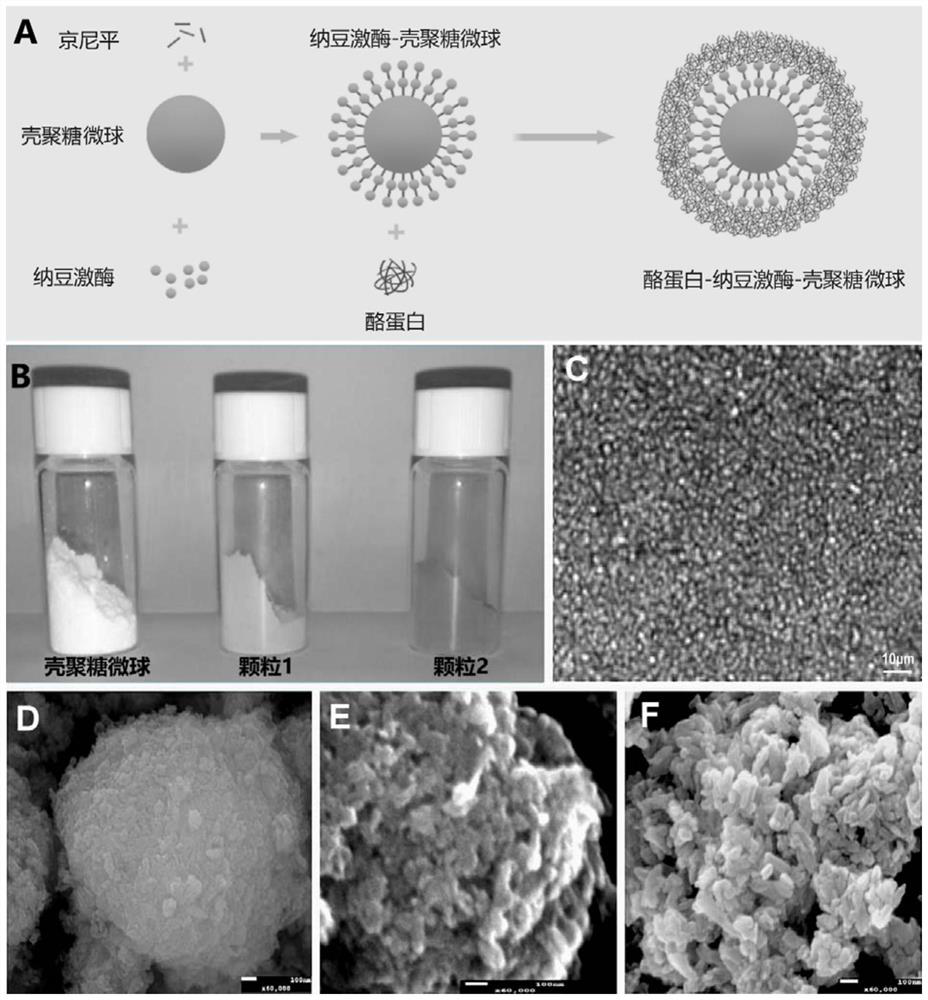

[0075] Embodiment 1: chitosan-nattokinase sustained-release microspheres

[0076] (1) Preparation of chitosan-nattokinase sustained-release microspheres

[0077] 1) The emulsifier and the organic solvent are mixed according to the volume ratio of emulsifier: organic solvent=1:50 to obtain an oil phase, wherein the emulsifier used is span-80, and the organic solvent used is liquid paraffin;

[0078] 2) Chitosan is added to an acetic acid solution with a volume concentration of 3%, magnetically stirred for 2 hours to make it fully dissolved, left to stand, and made into an aqueous phase with a mass concentration of chitosan of 0.5%;

[0079] 3) dissolving sodium tripolyphosphate in water to prepare crosslinking agent A with a concentration of sodium tripolyphosphate of 10 mg / ml;

[0080] 4) dissolving genipin in 30% ethanol solution to prepare a cross-linking agent B with a genipin concentration of 3 mg / ml;

[0081] 5) dispersing nattokinase in water to prepare an aqueous solu...

Embodiment 2

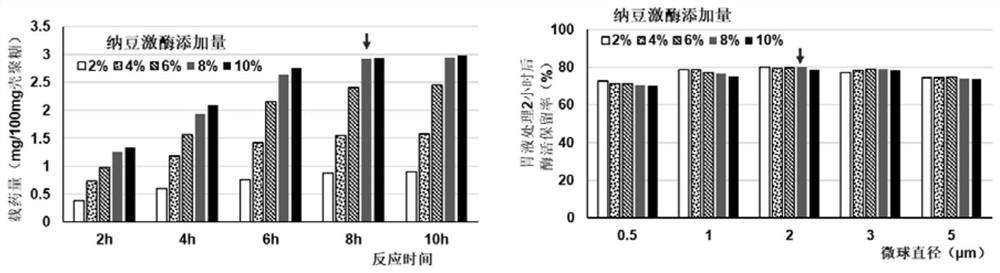

[0088] Optimization of Preparation Conditions of Chitosan-Nattokinase Sustained Release Microspheres

[0089] 1) The emulsifier and the organic solvent are mixed according to the volume ratio of emulsifier: organic solvent=1:50 to obtain an oil phase, wherein the emulsifier used is span-80, and the organic solvent used is liquid paraffin;

[0090] 2) Chitosan is added to an acetic acid solution with a volume concentration of 3%, magnetically stirred for 2 hours to make it fully dissolved, left to stand, and made into an aqueous phase with a chitosan mass concentration of 0.5%;

[0091] 3) dissolving sodium tripolyphosphate in water to prepare crosslinking agent A with a concentration of sodium tripolyphosphate of 10 mg / ml;

[0092] 4) dissolving genipin in 30% ethanol solution to prepare a cross-linking agent B with a genipin concentration of 3 mg / ml;

[0093] 5) dispersing nattokinase in water to prepare an aqueous solution with a concentration of 50 mg / ml;

[0094] 6) Acco...

Embodiment 3

[0100] Embodiment 3: the preparation of chitosan-nattokinase sustained-release microspheres

[0101] 1) The emulsifier and the organic solvent are mixed according to the volume ratio of emulsifier: organic solvent=1:50 to obtain an oil phase, wherein the emulsifier used is span-80, and the organic solvent used is liquid paraffin;

[0102] 2) Chitosan is added to an acetic acid solution with a volume concentration of 3%, magnetically stirred for 2 hours, fully dissolved, left to stand, and made into an aqueous phase with a chitosan mass concentration of 3%;

[0103] 3) dissolving sodium tripolyphosphate in water to prepare crosslinking agent A with a concentration of sodium tripolyphosphate of 30 mg / ml;

[0104] 4) dissolving genipin in 90% ethanol solution to prepare a cross-linking agent B with a genipin concentration of 10 mg / ml;

[0105] 5) dispersing nattokinase in water to prepare an aqueous solution with a concentration of 50 mg / ml;

[0106] 6) According to the volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com