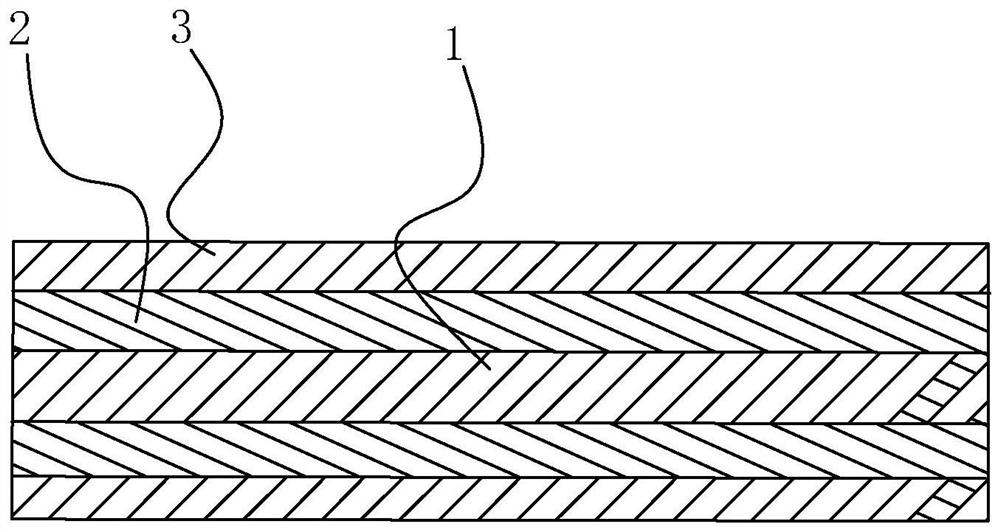

A kind of asphalt waterproof membrane and preparation method thereof

A kind of asphalt waterproof membrane and asphalt technology, which is applied in the direction of asphalt layered products, chemical instruments and methods, building insulation materials, etc., can solve the problems of waterproof membranes such as low temperature resistance, poor anti-aging performance, and short service life of waterproof membranes , to achieve the effect of improving deformation resistance, prolonging service life and improving ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0039] The waste tires in the following preparation examples were purchased from Qingdao Xinsheng Transportation Facilities Co., Ltd., and the glass fiber cotton was purchased from Langfang Yimei Energy Conservation Co., Ltd.

[0040] Preparation example of rubber powder:

[0041] S1: Use a shredder to shred waste tires;

[0042] S2: Sieve the crushed waste tires to obtain 60-70 mesh rubber powder.

[0043] Preparation example of modified glass fiber cotton

[0044] Glycolic acid, formic acid and ethyl acrylate in the following preparation examples were all purchased from Shanghai Yuna Chemical Co., Ltd., and the acrylic resin was a water-soluble acrylic resin purchased from Foshan Byton New Material Co., Ltd.

preparation example 1

[0046] S1: Weigh 80Kg of water, 2Kg of glycolic acid, 1Kg of formic acid, 12Kg of acrylic resin and 10Kg of ethyl acrylate according to the proportion, add water, glycolic acid, formic acid, acrylic resin and ethyl acrylate into the stirring tank, and stir at room temperature for 1.5h , rotating speed is 30r / min, obtains acid modifier;

[0047] S2: Use a pulverizer to pulverize the glass fiber cotton block to obtain glass fiber cotton;

[0048] S3: Add the glass fiber cotton obtained by adding S2 whose weight is 30% of the acid modifier weight into the stirring tank stirring the acid modifier. After adding the glass fiber cotton, use the stirring tank to mix the acid modifier and glass fiber cotton Stirring, the rotating speed is 30r / min, and the stirring time is 1h to obtain modified glass fiber cotton;

[0049] S4: After stirring, filter the acid modifier and glass fiber wool; after filtering out the glass fiber wool, spread the glass fiber wool, and dry the glass fiber wool ...

preparation example 2

[0051] S1: Weigh water, glycolic acid and formic acid according to the proportion, add water, glycolic acid and formic acid into the stirring tank, stir at a stirring speed of 30r / min, and stir at room temperature for 1.5h to obtain an acidic modifier;

[0052] S2: Use a pulverizer to pulverize the bulk glass fiber cotton;

[0053] S3: Add the glass fiber cotton obtained by adding S2 whose weight is 30% of the acid modifier weight into the stirring tank stirring the acid modifier. After adding the glass fiber cotton, use the stirring tank to mix the acid modifier and glass fiber cotton Stir, the stirring speed is 30r / min, and the stirring time is 1h;

[0054] S4: After stirring, filter the acid modifier and glass fiber wool; after filtering out the glass fiber wool, spread the glass fiber wool, and dry the glass fiber wool naturally to obtain the modified glass fiber wool.

[0055] Glass fiber cotton preparation example 1:

[0056] S1: Use a pulverizer to crush the glass fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com