Non-prestressed galvanized steel pipe-ultra-high performance concrete composite electric pole and preparation method thereof

A galvanized steel pipe, ultra-high-performance technology, applied in the field of electric poles, can solve the problems of poor corrosion resistance, high brittleness of annular concrete poles, and self-heavyness, etc., and achieve strong corrosion resistance, good anti-collision and collapse performance, and rigidity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

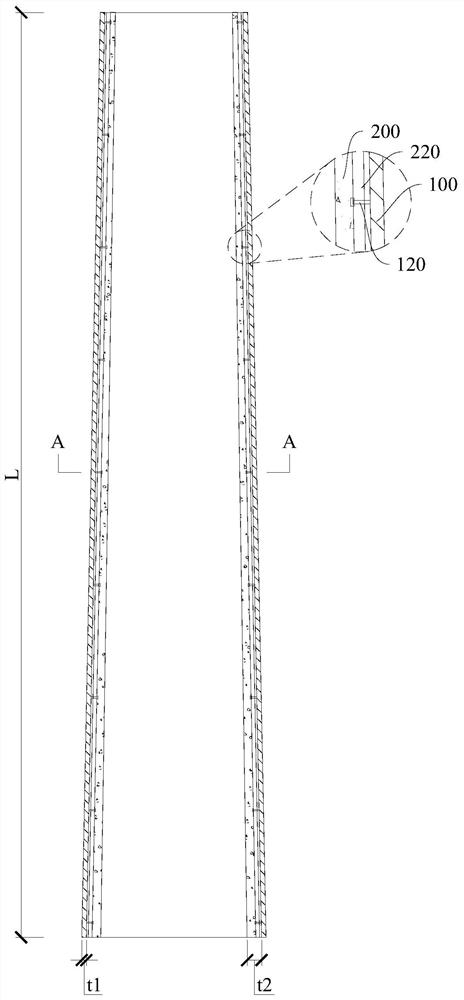

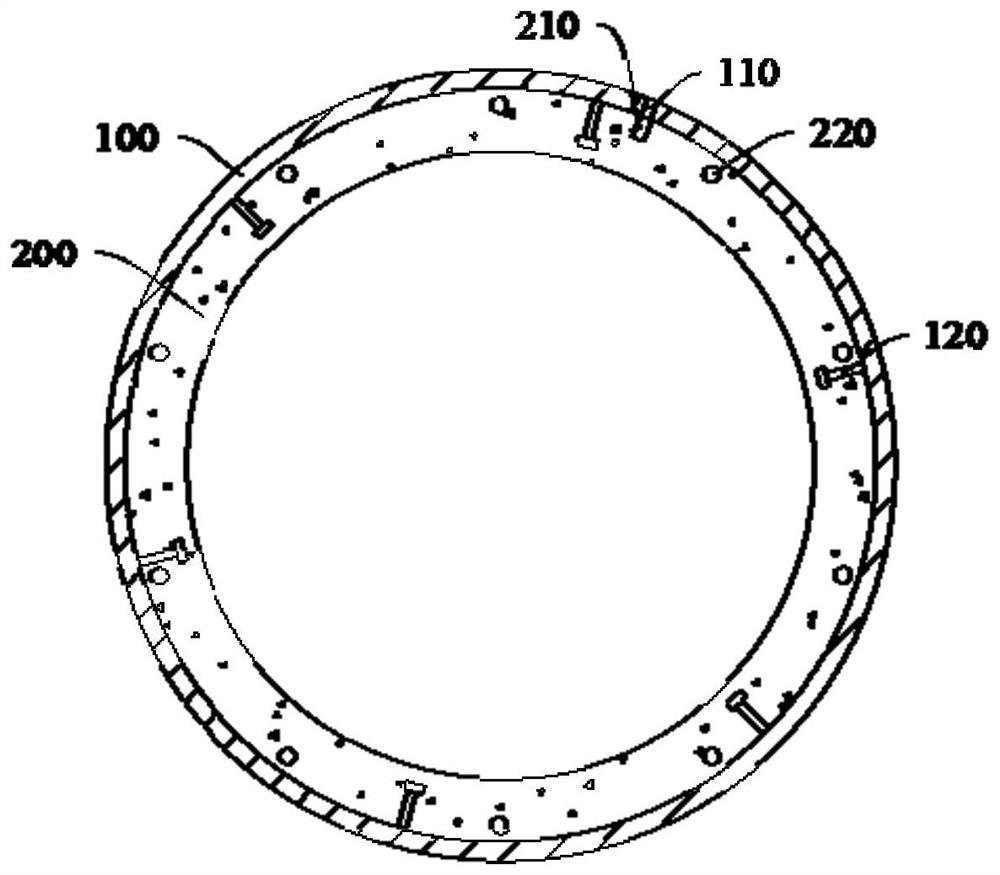

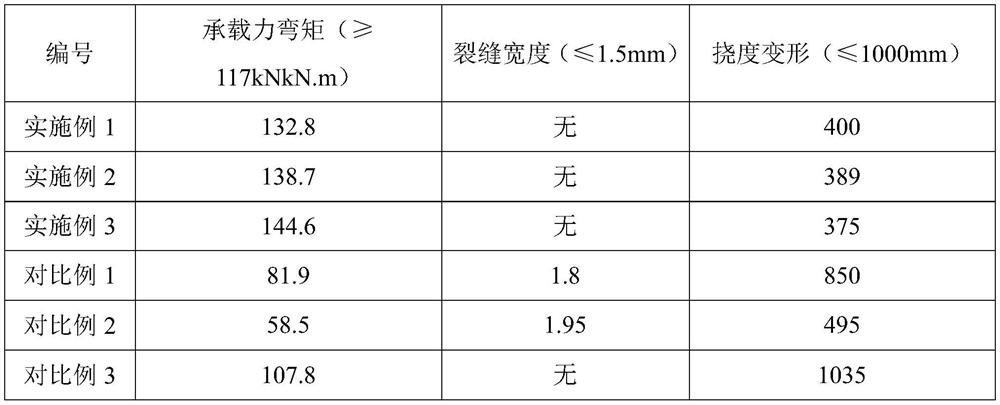

[0029] combine Figure 1~2 As shown, a M grade non-prestressed galvanized steel pipe-ultra-high performance concrete composite pole with a slightly diameter of 190mm and a length (L) of 12m, including galvanized steel pipe 100 and ultra-high performance concrete poured on the inner wall of galvanized steel pipe 100 For the layer 200, the thickness t1 of the galvanized steel pipe 100 is 1.5 mm, the thickness of the galvanized layer is 20 μm, and the thickness t2 of the ultra-high performance concrete layer 200 is 20 mm.

[0030] The galvanized steel pipe 100 has two rows of reserved holes 110 with a diameter of 14 mm along the length direction. The spacing between the reserved holes 110 is 200 mm. Nut 210, in this embodiment, the nut 210 pre-embedded in the ultra-high performance concrete layer 200 is used to fix the ladder. The nuts 210 in the layer 200 are connected. It can be understood that the pre-embedded nut 210 can also be used to fix other supports, and the pre-embed...

Embodiment 2

[0041] combine Figure 1~2 As shown, a M grade non-prestressed galvanized steel pipe-ultra-high performance concrete composite pole with a slightly diameter of 190mm and a length (L) of 12m, including galvanized steel pipe 100 and ultra-high performance concrete poured on the inner wall of galvanized steel pipe 100 For the layer 200, the thickness t1 of the galvanized steel pipe 100 is 3 mm, the thickness of the galvanized layer is 40 μm, and the thickness t2 of the ultra-high performance concrete layer 200 is 80 mm.

[0042] The galvanized steel pipe 100 is reserved with two rows of reserved holes 110 with a diameter of 20 mm along the length direction. The spacing between the reserved holes 110 is 300 mm. Nut 210, in this embodiment, the nut 210 pre-embedded in the ultra-high performance concrete layer 200 is used to fix the ladder. The nuts 210 in the layer 200 are connected. It can be understood that the pre-embedded nut 210 can also be used to fix other supports, and th...

Embodiment 3

[0053] combine Figure 1~2 As shown, a M grade non-prestressed galvanized steel pipe-ultra-high performance concrete composite pole with a slightly diameter of 190mm and a length (L) of 12m, including galvanized steel pipe 100 and ultra-high performance concrete poured on the inner wall of galvanized steel pipe 100 For the layer 200, the thickness t1 of the galvanized steel pipe 100 is 2.2 mm, the thickness of the galvanized layer is 30 μm, and the thickness t2 of the ultra-high performance concrete layer 200 is 50 mm.

[0054] The galvanized steel pipe 100 has two rows of reserved holes 110 with a diameter of 17 mm along the length direction. The spacing between the reserved holes 110 is 250 mm. Nut 210, in this embodiment, the nut 210 pre-embedded in the ultra-high performance concrete layer 200 is used to fix the ladder. The nuts 210 in the layer 200 are connected. It can be understood that the pre-embedded nut 210 can also be used to fix other supports, and the pre-embed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com