De-winding plating method for TOPCon battery and preparation method of TOPCon battery

A wrapping and battery technology, applied in the field of solar cells, can solve problems such as increasing costs, increasing equipment, increasing cleaning processes, etc., to improve open-circuit voltage and short-circuit current, ensure fluidity and uniformity, and increase water film protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

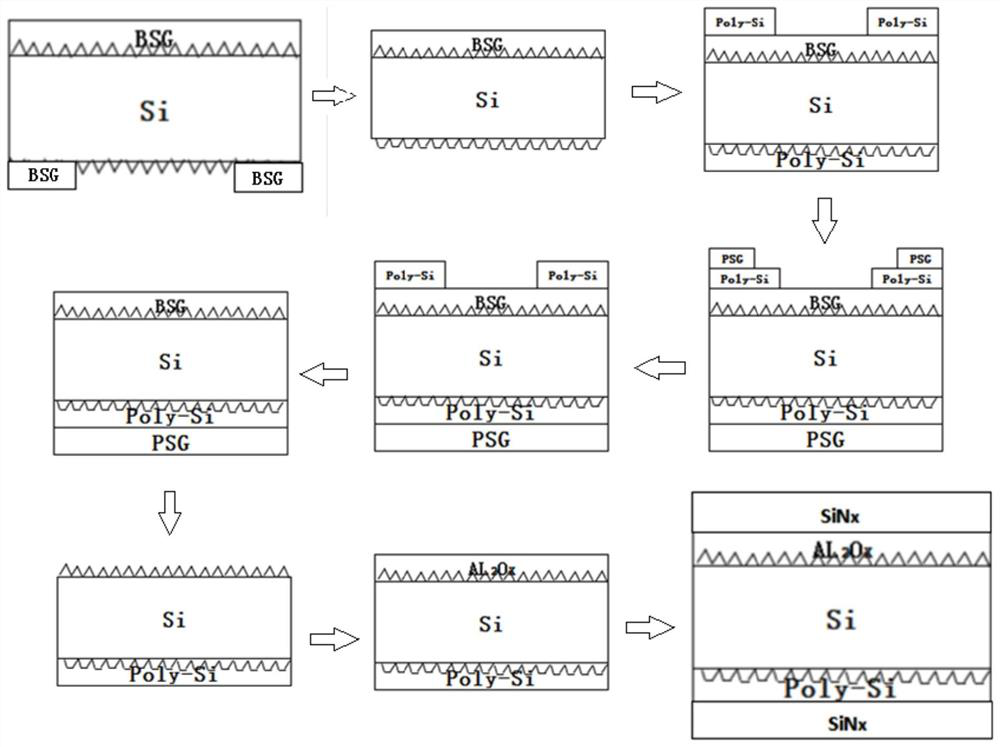

[0036] Adopt the above-mentioned dewinding plating method for TOPCon battery to prepare the preparation method of TOPCon battery and comprise the steps:

[0037] Front-side boron doping of single crystal N-type raw silicon wafers after texturing; using HF / HNO 3 Mix acid solution to etch and polish the back and edge of the silicon wafer; use alkaline solution for secondary polishing; deposit tunnel oxide layer and polysilicon layer (Poly-Si); do phosphorus doping (PSG) on the back; remove front winding coating; removal of glass layers (BSG and PSG); deposition of aluminum oxide (Al 2 o 3 ); silicon nitride double-sided coating (N x o y ), wherein the thickness of the silicon nitride film is 70-90nm on the front side and 50-70nm on the back side; printing and sintering test. The schematic diagram of the specific preparation process is as follows: figure 1 shown.

Embodiment 1

[0040] A kind of method for going around plating of TOPCon battery, comprises the steps:

[0041] S1, Texturing a single crystal N-type silicon wafer of 156.75mm×156.75mm, performing boron diffusion doping on the front side of the silicon wafer after texturing, and phosphorus doping after depositing a tunneling oxide layer and a polysilicon layer on the backside;

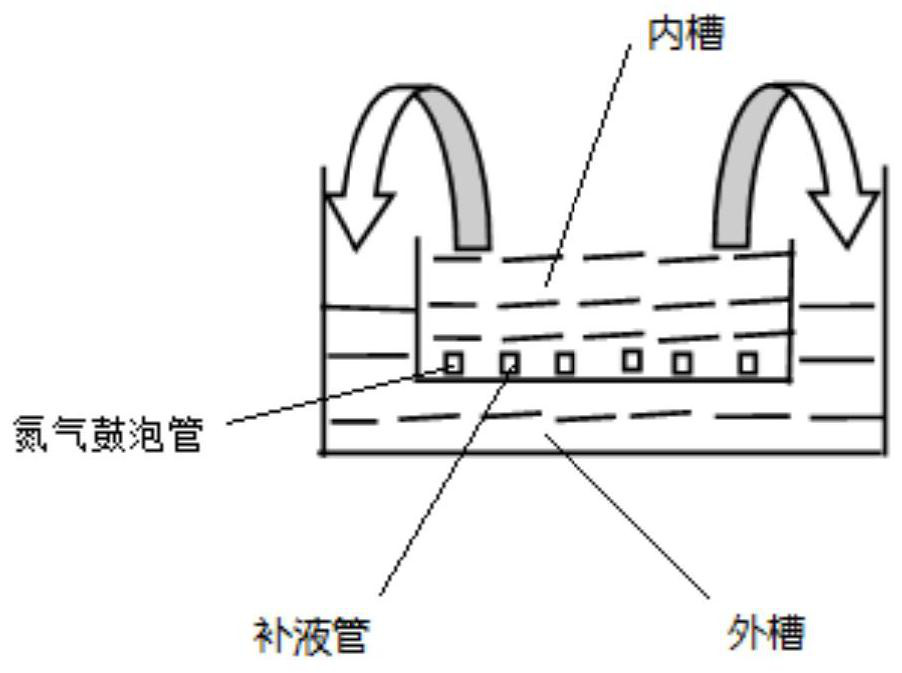

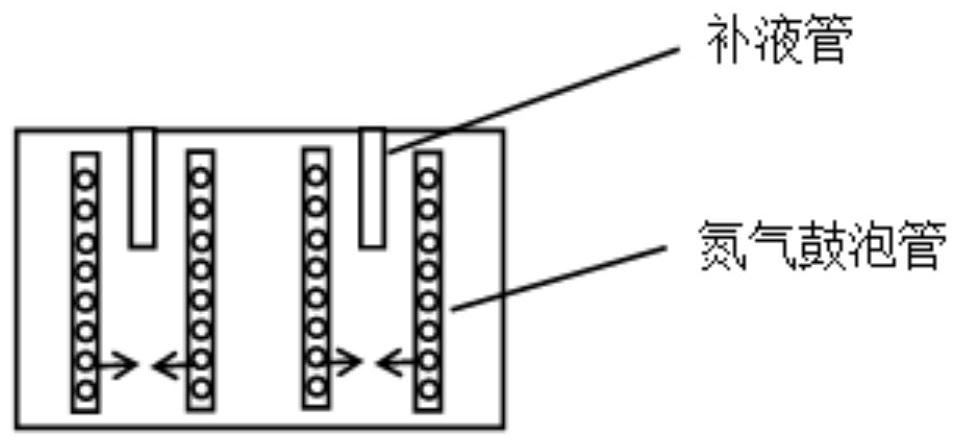

[0042] S2, using a shower nozzle with a water volume of 150mL / min, spraying a water film layer on the back of the phosphorus-doped silicon wafer, using a chain pickling equipment, and using a roller to transport the single side of the silicon wafer to immerse in hydrogen with a concentration of 49% In the hydrofluoric acid solution, soak the front side of the silicon wafer in the hydrofluoric acid solution for 2 minutes to remove the phosphorous around the front and side plating;

[0043] S3, put the silicon wafer obtained in step S2 into KOH solution or NaOH solution containing additives, soak at 60°C for 5 minutes...

Embodiment 2

[0048] A kind of method for going around plating of TOPCon battery, comprises the steps:

[0049] S1, Texturing a single crystal N-type silicon wafer of 156.75mm×156.75mm, performing boron diffusion doping on the front side of the silicon wafer after texturing, and phosphorus doping after depositing a tunneling oxide layer and a polysilicon layer on the backside;

[0050] S2, using a shower nozzle with a water volume of 50mL / min, spraying a water film layer on the back of the phosphorus-doped silicon wafer, using chain pickling equipment, and using a roller to transport the silicon wafer on one side and immersing it in hydrogen with a concentration of 40% In the hydrofluoric acid solution, soak the front side of the silicon wafer in the hydrofluoric acid solution for 3 minutes to remove the phosphorous around the front and side plating;

[0051] S3, put the silicon wafer obtained in step S2 into a KOH solution containing additives, soak at 55°C for 10 minutes, remove the polys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com