Multi-functional electrically and thermally conductive adhesive tape

A technology of electrical and thermal conductivity, conductive tape, applied in the direction of adhesive, conductive adhesive connection, chemical instruments and methods, etc., can solve the problems of low thermal conductivity and insulation, and achieve high precision and precision, simple process, low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0046] Figure 4A to Figure 4C It shows a sectional view of the manufacturing process of the conductive and thermally conductive adhesive tape according to the second embodiment of the present invention.

[0047] Please refer to Figure 4A , provide a substrate 300, this substrate can be a plastic film, such as polypropylene (PP), polyethylene terephthalate (PET), polyethylene (PE), polyethylene glycol terephthalate (PEN), polyimide film (PI), polyvinyl chloride (PVC) film or other materials. Then, a metal layer 301 is compounded to cover a surface of the substrate 300 to form a composite film structure. Wherein, the material of the metal layer 301 can be a metal vapor-deposited film such as vapor-deposited aluminum film or a laminated or thermocompressed metal foil. The metal foil can be copper foil, aluminum foil, single-sided or double-sided electroplated silver-copper alloy , silver-plated, tin-lead-plated, chrome-plated, nickel-plated, gold-plated copper foil, etc. or ...

Embodiment 3

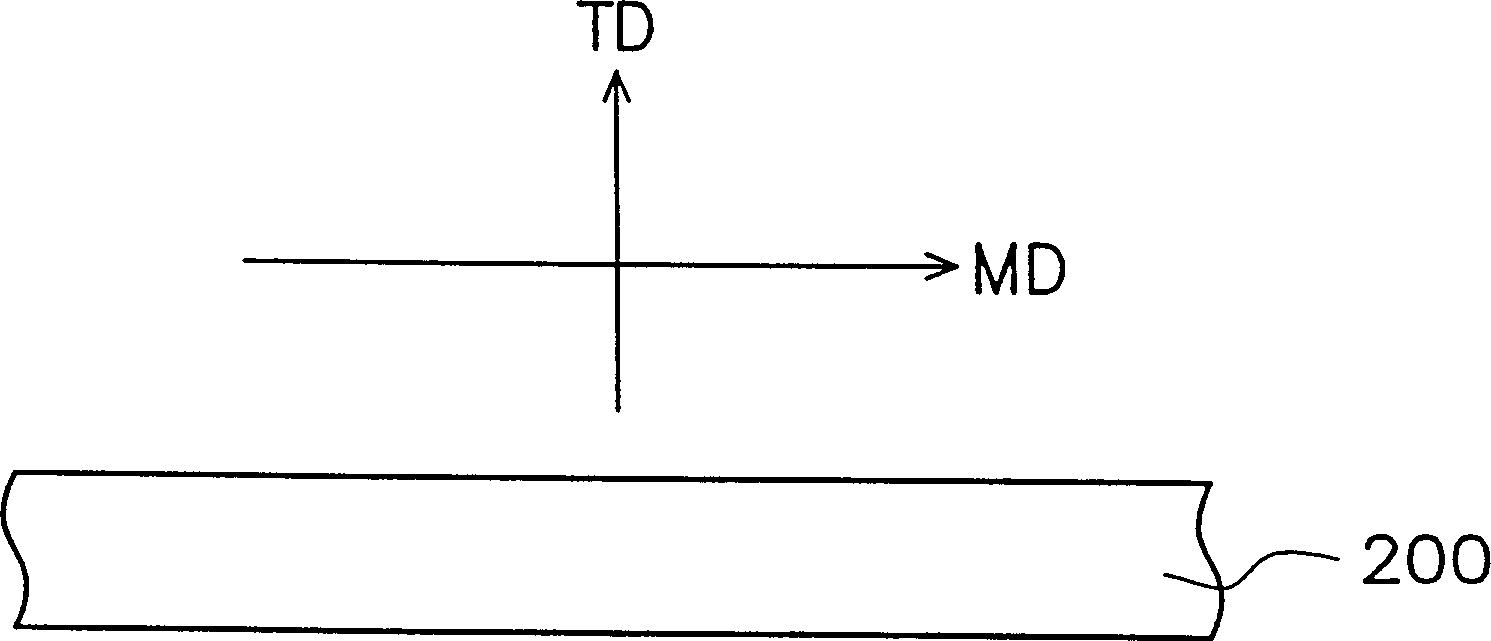

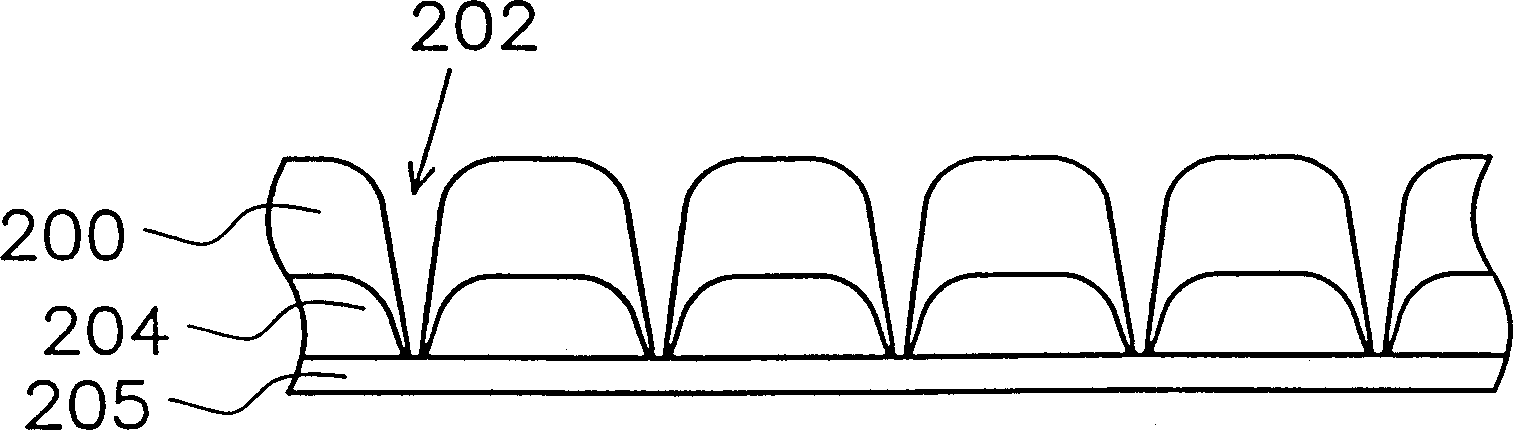

[0052] Please refer to Fig. 6, with the substrate 200 using the metal layer in the first embodiment, it is recommended to use tin-plated copper foil, and coat an adhesive layer 204 on one side, and the selection of the material for the adhesive layer 204 is based on the best product quality. The application is mainly based on pure rubber, conductive glue or thermal conductive glue. It is recommended to use pure glue, and the pure glue can be any glue, such as polypropylene glue, silica gel, rubber, hot melt glue, epoxy resin etc. In practice, a release layer 205 is pasted on the other side of the adhesive layer 204, and the release layer 205 can be a release paper or a release film. Then, the rolling action is carried out, such as using diamond wheels, diamond platform rolling machines, pointed wheels or other rolling machines for rolling. When rolling, the rolling direction is from the substrate side to the The direction of the adhesive layer is rolled, and when rolling, a p...

Embodiment 4

[0058] Using a metal substrate 200 similar to that in Embodiment 1, it is recommended to use a composite metal foil of tin and copper or tin-lead and copper, and coat an adhesive layer 204 on one side. The selection of the adhesive layer material is based on the best product. The application occasions are mainly pure glue, conductive glue or heat conduction glue. The pure glue system can be any glue system, such as polypropylene glue, silica gel, rubber, hot melt glue, epoxy resin and the like. After that, in practice, a release layer 205 is pasted on the other side of the adhesive layer 204, and the release layer 205 can be a release paper or a release film. Then, the rolling action is carried out, such as using a diamond wheel, a diamond platform rolling machine, a pointed wheel or other rolling machines for rolling. When rolling, the rolling direction is from the substrate side to the The direction of the adhesive layer is rolled, and when rolling, the metal substrate 200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com