Two-component normal-temperature cured epoxy resin elastomer composition and preparation method thereof

An epoxy resin reactive diluent, epoxy resin technology, applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc., can solve the problem of high tensile strength, low elongation at break, and inability to achieve elastic bonding and other problems, to achieve the effect of good low temperature flexibility, high tensile elongation at break, which is conducive to application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

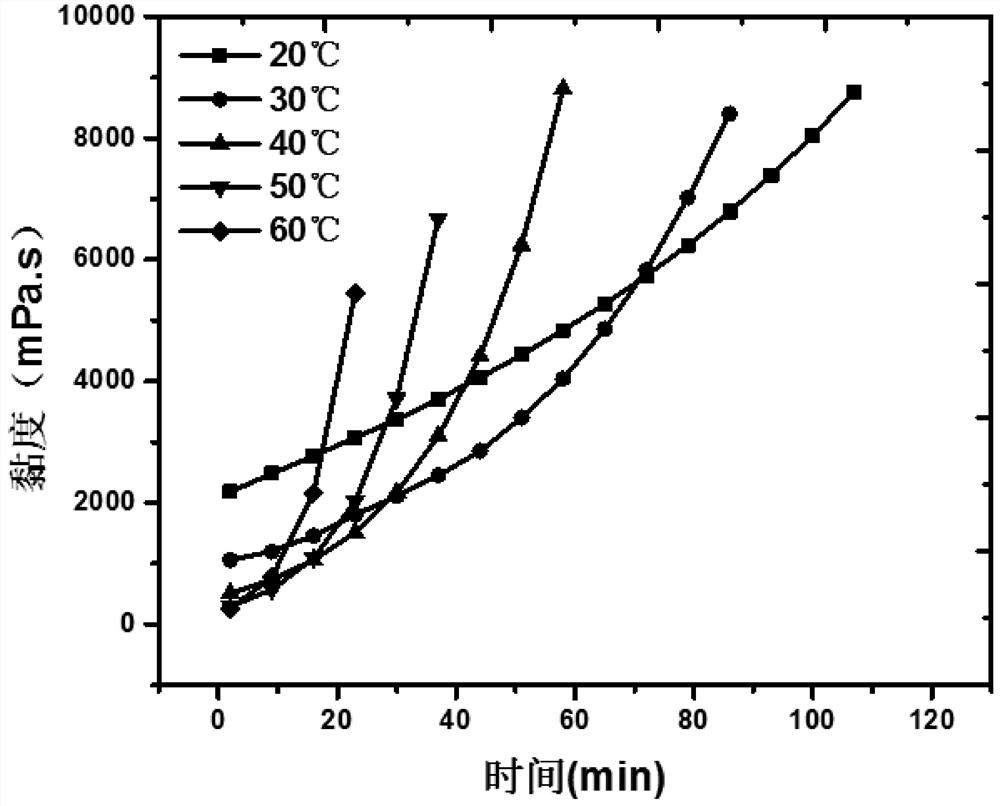

Embodiment 1

[0045] This embodiment provides a two-component room temperature curing epoxy resin elastomer composition and its preparation method, including the following raw materials in parts by weight:

[0046] 1) A component epoxy resin: epoxy resin (E-51, Baling Petrochemical) 100 parts, rubber modified epoxy resin (HyPox RA1340, CVC company) 11.8 parts, epoxy reactive diluent (1,4- butanediol diglycidyl ether) 14.2 parts;

[0047] 2) B-component epoxy curing agent: 100 parts of liquid monoamine curing agent (9-octadecylamine, Solvay Chemical Company), 41.5 parts of polyurethane prepolymer (HC-9975, Shanghai Crane City Polymer Company) Parts, adhesion promoter (according to mass ratio 593: cardanol: diphenolic propane = 0.53: 3.82: 1.29) 5.64 parts;

[0048] Wherein, the weight ratio of A component epoxy resin and B component epoxy curing agent is 1:1;

[0049] 3) A method for preparing a two-component room temperature curing epoxy resin elastomer composition, comprising the followi...

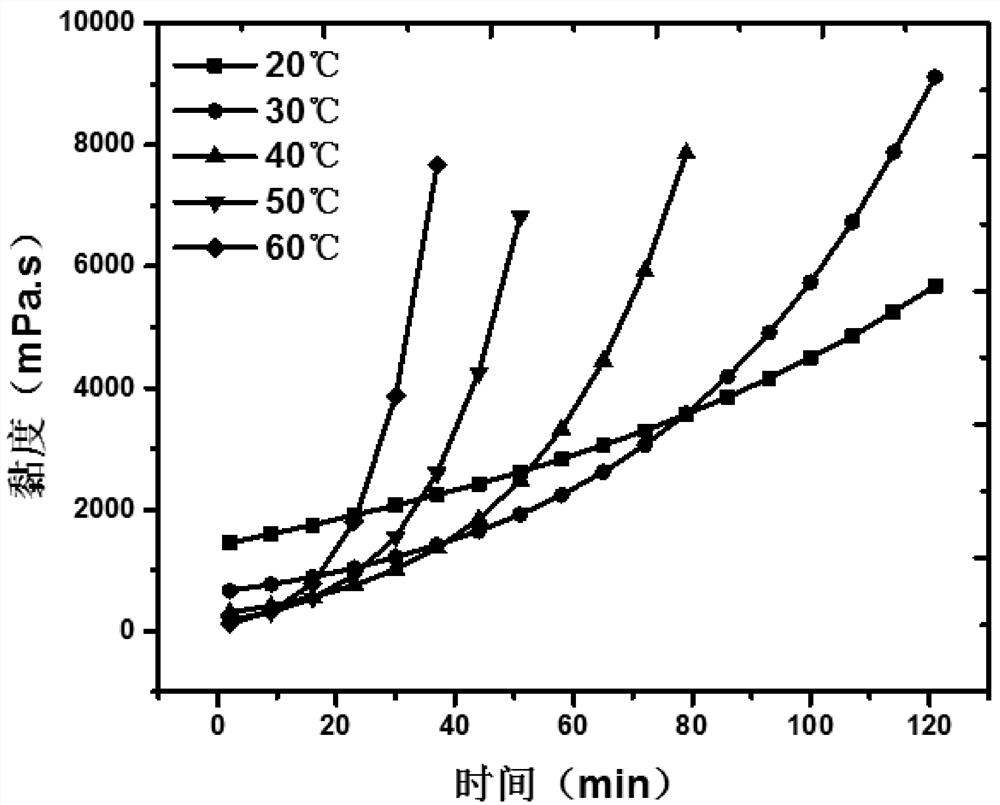

Embodiment 2

[0054] 1) A-component epoxy resin: epoxy resin (E-51, Taiwan Nanya) 100 parts, polyurethane modified epoxy resin (NPER-133L, Taiwan Nanya) 17.4 parts, epoxy resin reactive diluent (C12-14 6.6 parts of alkyl glycidyl ether, 4.4 parts of trimethylolpropane triglycidyl ether) 11 parts;

[0055] 2) B-component epoxy curing agent: 100 parts of liquid monoamine curing agent (JEFFAMINE®M-2005, XTJ-435, XTJ-436, mixed according to the molar mass ratio of 1:0.36:0.65), polyurethane prepolymer (H2128A , Zibo Huatian Chemical Co., Ltd.) 31.5 parts, adhesion promoter (according to the mass ratio of 593: cardanol: diphenolic propane = 0.25: 5.80: 1.56) 7.61 parts;

[0056] Wherein, the weight ratio of A component epoxy resin and B component epoxy curing agent is 1:0.86;

[0057] 3) The preparation method refers to Example 1, the difference is that in step 1, the temperature of the reaction kettle is 65° C., and the reaction time is 60 minutes; in step 2, the temperature is 75° C., and the...

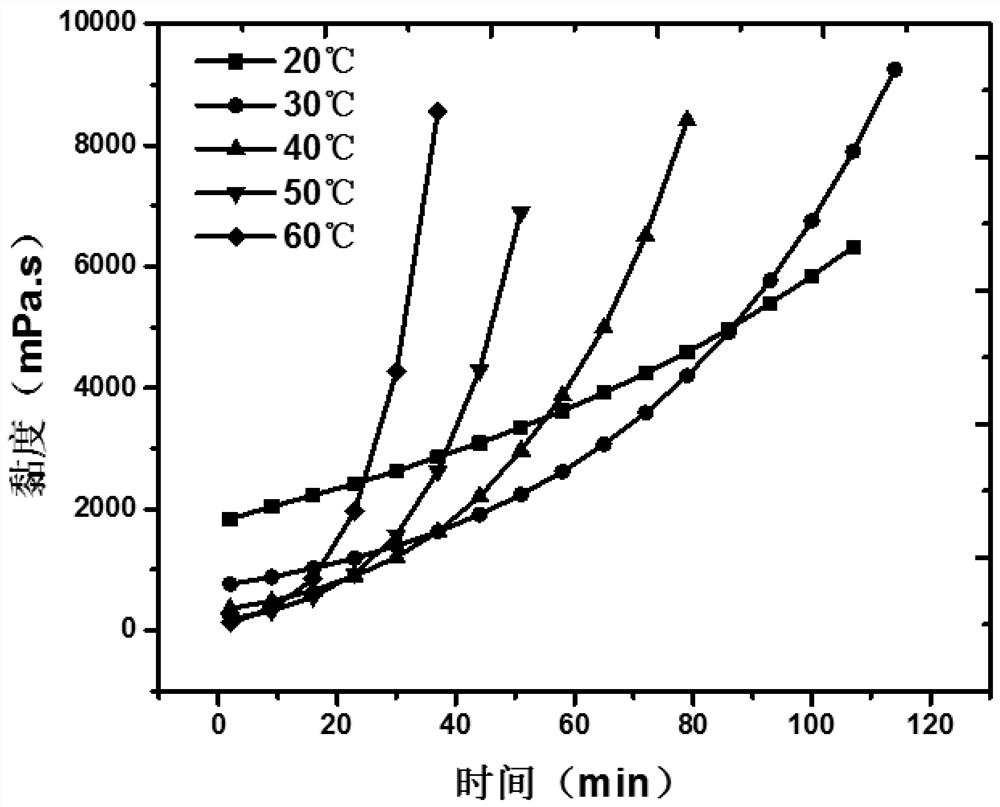

Embodiment 3

[0059] 1) A component epoxy resin: epoxy resin (E-51, Baling Petrochemical) 100 parts, rubber modified epoxy resin (HyPox RF95, CVC company) 9.2 parts and polyurethane modified epoxy resin (NPER-133L , South Asia Resin Company) 6.5 parts, a total of 15.7 parts, epoxy resin reactive diluent (1,4-butanediol diglycidyl ether 6.3 parts, C12-14 alkyl glycidyl ether 7.4 parts, Junqiao New Materials (Shenzhen ) limited company) 13.7 copies;

[0060] 2) B-component epoxy curing agent: liquid monoamine curing agent (cyclohexylmethylamine, cyclopentylmethylamine, mixed according to the molar ratio of 1:0.78) 100 parts, polyurethane prepolymer (H1342, Zibo Huatian Chemical Co., Ltd. Company) 19.5 parts, adhesion promoter (according to mass ratio 593: cardanol: diphenolic propane = 0.29: 6.03: 2.15) 8.48 parts;

[0061] Wherein, the weight ratio of A component epoxy resin and B component epoxy curing agent is 1:1.13;

[0062] 3) The preparation method refers to Example 1, the difference...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com