Method for preparing organosilicon foam using hydrogen-containing silicone oil modified by phosphorus flame retardant

A technology of silicone foam and phosphorus-based flame retardant, which is applied in the field of preparing silicone foam from hydrogen-containing silicone oil, can solve the problem of affecting the flame-retardant performance and other properties of silicone foam materials, and cannot accurately and quantitatively introduce hydroxyl-terminated phosphorus-based flame retardant. It can improve the flame retardant effect, avoid hydrolysis and degradation, and achieve the effect of high flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

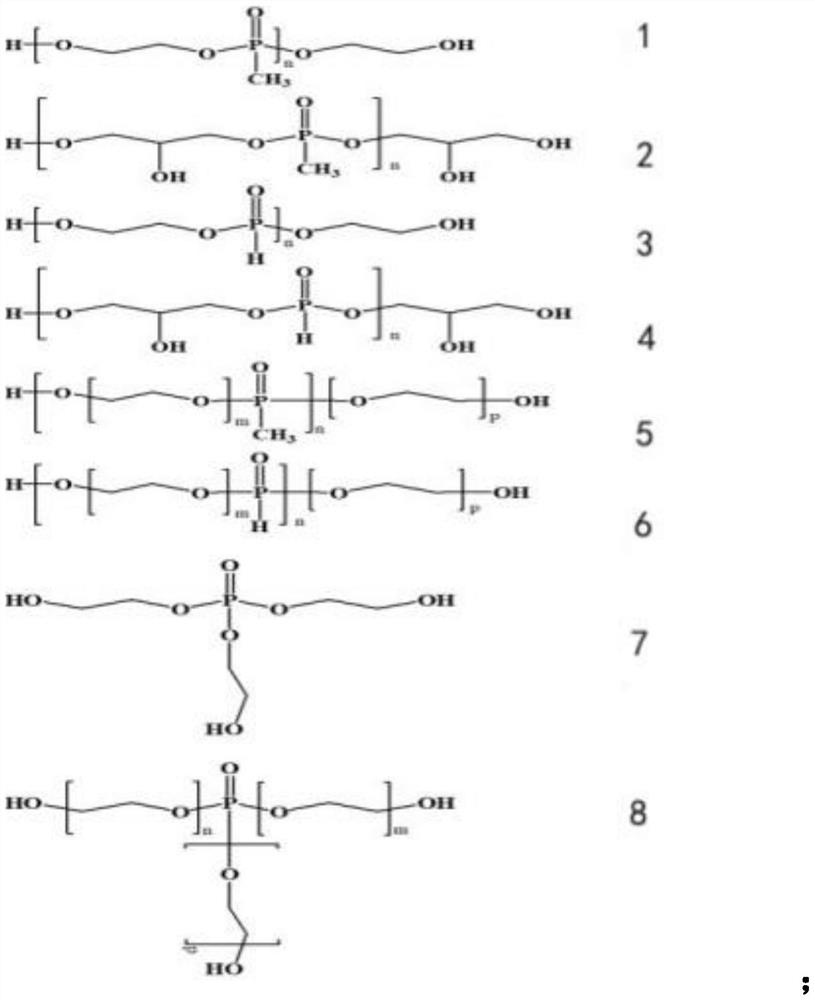

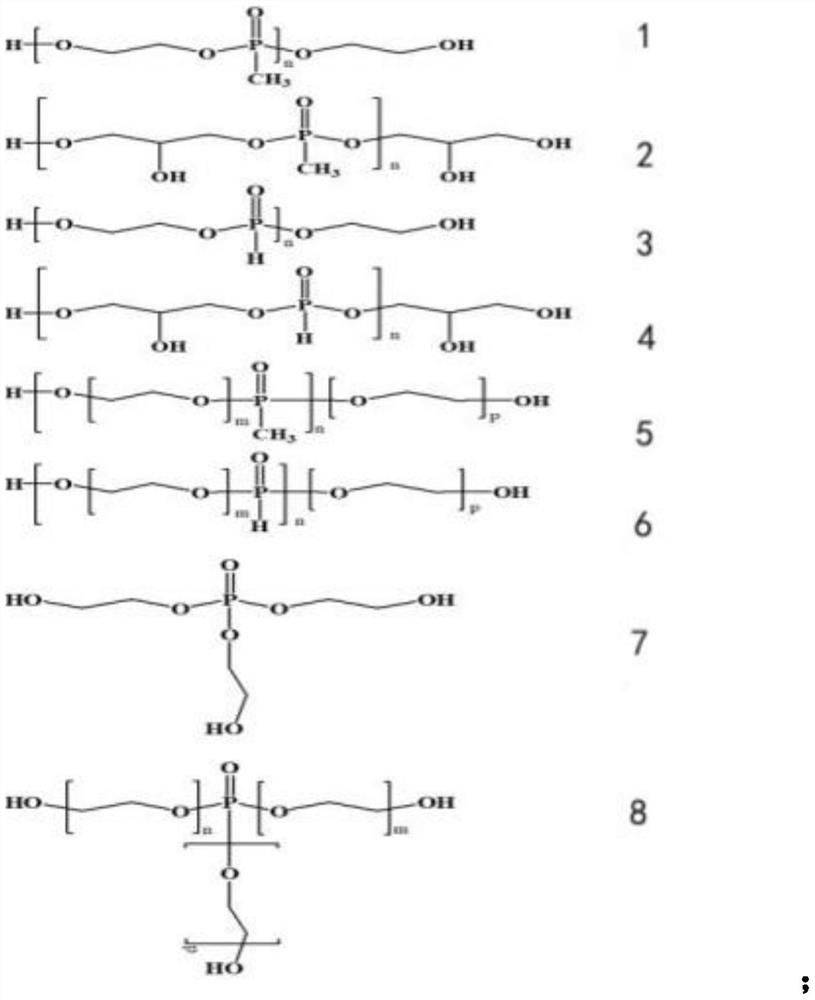

Image

Examples

Embodiment 1

[0026] The method for preparing organosilicon foam by utilizing hydrogen-containing silicone oil modified by phosphorus-based flame retardant comprises the following steps:

[0027] S1. Mix hydrogen-containing silicone oil, hydroxyl-terminated phosphorus-based liquid flame retardant and the first catalyst according to the weight ratio of (16-234): (8-60): (0.8-6), preferably the amount of weight is ( 20-195): (10-50): (1-5), under nitrogen protection atmosphere and temperature conditions of 30-80°C, the silicon-hydrogen bond in the hydrogen-containing silicone oil and the hydroxyl-terminated phosphorus-based liquid flame retardant The hydroxyl group reaction, the ratio of the amount of the Si-H bond in the hydrogen-containing silicone oil to the amount of the hydroxyl group in the hydroxyl-terminated phosphorus-based liquid flame retardant is (2.4-12): (0.8-2.4), preferably ( 3-10): (1-2), react for 15-45 minutes to obtain hydrogen-containing silicone oil modified by phosphoru...

Embodiment 2

[0041]S1. Add 130 grams of trimethylsiloxy-terminated polyhydrocarbyl hydrogen siloxane, 13 grams of dimethyl phosphite and ethylene glycol reaction product (compound 3) and 1 gram of monobutyltin oxide catalyst in the there-necked flask , under a nitrogen atmosphere, control the reaction temperature at 80°C, and react for 20 minutes to obtain a hydrogen-containing silicone oil modified with a phosphorus-based flame retardant, which is product A;

[0042] S2. Weigh 62 grams of hydroxyl-terminated polymethylsiloxane with a viscosity of 3370 cP, 12 grams of vinyl-terminated polymethylsiloxane, and 4 grams of dibutyltin dilaurate, and stir evenly to obtain product B;

[0043] S3. Add 24 grams of product A to product B, stir evenly with a high-speed stirring paddle, pour it into the mold and let it stand, wait until the mixture in the mold turns into a white non-sticky translucent gel-like solid, take it out, and get product C;

[0044] S4. Put product C into a high-temperature ov...

Embodiment 3

[0048] S1. Add 130 grams of trimethylsiloxy-terminated polyhydrocarbyl hydrogen siloxane, 13 grams of dimethyl phosphite and ethylene glycol reaction product (compound 3) and 1 gram of monobutyltin oxide catalyst in the there-necked flask , under a nitrogen atmosphere, control the reaction temperature at 80°C, and react for 20 minutes to obtain a hydrogen-containing silicone oil modified with a phosphorus-based flame retardant, which is product A;

[0049] S2. Weigh 56 grams of hydroxyl-terminated polymethylsiloxane with a viscosity of 2240 cP, 12 grams of vinyl-terminated polymethylsiloxane, and 5 grams of dibutyltin dilaurate, and stir evenly to obtain product B;

[0050] S3. Add 36 grams of product A to product B, stir evenly with a high-speed stirring paddle, pour it into the mold and let it stand, wait until the mixture in the mold becomes a white non-sticky translucent gel-like solid, then take it out to obtain product C;

[0051] S4. Put product C into a high-temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com