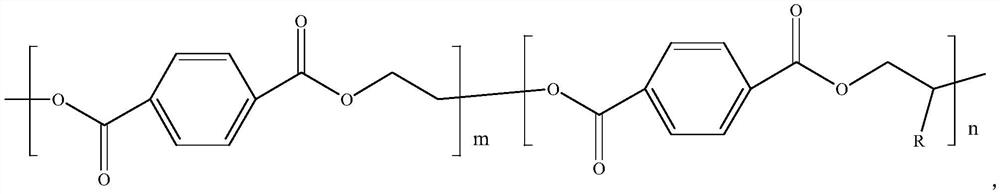

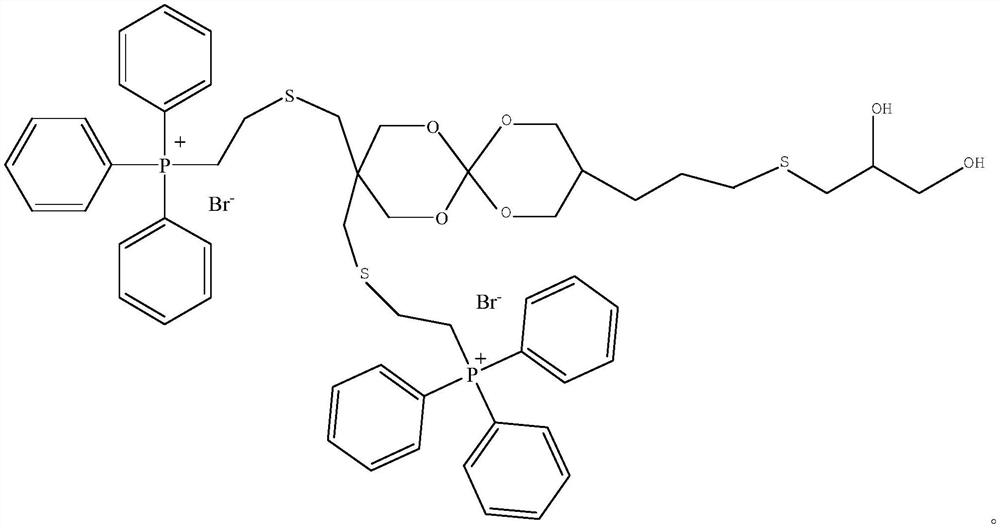

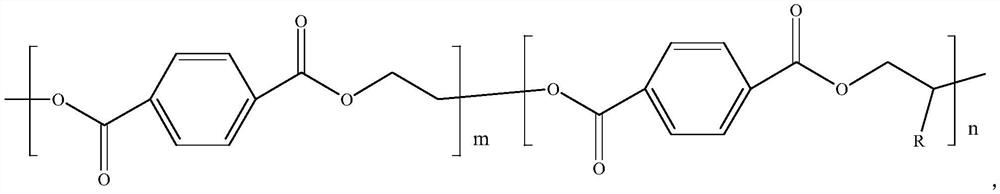

An antibacterial and antistatic polyester film

A polyester film, antistatic technology, applied in the field of polyester film, can solve the problems of complex process, time-consuming and laborious, and achieve the effect of reducing porosity, reducing film pores, and avoiding charge accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will now be described in further detail with reference to the embodiments.

[0036] The antibacterial and antistatic polyester film is prepared by the following method: Weigh the components in proportion, mix them thoroughly, heat and dry them, and then add them to the melt extrusion equipment for extrusion, and then stretch, heat-set, and cool. , and winding to obtain an antibacterial and antistatic polyester film.

[0037] Among them, the extrusion temperature is 230-300 ℃; the stretching is biaxial stretching, the stretching temperature of longitudinal stretching is 80-110 ℃, the stretching ratio is 2.5-4.5 times, and the stretching temperature of transverse stretching is 110- 140℃, the stretching ratio is 2.5-4.5 times; the heat setting temperature is 230-250℃, and the cooling temperature is lower than 80℃.

[0038] The components and the amounts of the components in Examples 1-3 and Comparative Examples 1-3 are shown in Table 1.

[0039] Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com