Friction stir welding method for tungsten-boron-aluminum composite shielding material and strengthening process thereof

A composite shielding and friction stir technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of not meeting the requirements of material mechanical properties, affecting tensile properties, etc., to ensure purity and performance, and reduce frictional heat. accumulation, avoid the effect of excessive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The method of the present embodiment comprises the following steps:

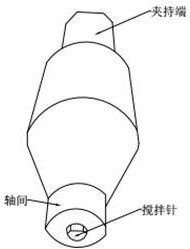

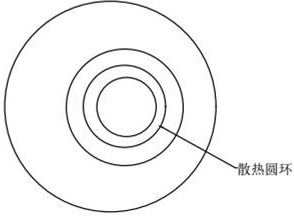

[0040] Step 1. Install the integrated tungsten steel stirring head in the friction stir welding equipment; the integrated tungsten steel stirring head is an integrated part between the clamping end, the stirring needle and the shaft, and a concentric heat dissipation ring is arranged between the shafts. Such as Figure 2a and Figure 2b shown;

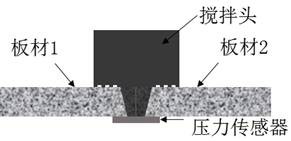

[0041] Step 2. Assemble and fix the two tungsten-boron-aluminum plates, and form the area to be welded between the opposite end faces of the two tungsten-boron-aluminum plates, obtain the components to be welded, and set the pressure sensor on the lower part of the components to be welded, and then set the integrated The pressure between the tungsten steel stirring head and the components to be welded is 10MPa, and the rotation speed of the integrated tungsten steel stirring head is 800r / min and the travel speed is 60r / min;

[0042] Step 3. Start the fricti...

Embodiment 2

[0047] The method of the present embodiment comprises the following steps:

[0048] Step 1. Install the integrated tungsten steel stirring head in the friction stir welding equipment; the integrated tungsten steel stirring head is an integrated part between the clamping end, the stirring needle and the shaft, and a concentric heat dissipation ring is arranged between the shafts. Such as Figure 2a and Figure 2bshown;

[0049] Step 2. Assemble and fix the two tungsten-boron-aluminum plates, and form the area to be welded between the opposite end faces of the two tungsten-boron-aluminum plates, obtain the components to be welded, and set the pressure sensor on the lower part of the components to be welded, and then set the integrated The pressure between the tungsten steel stirring head and the components to be welded is 30MP, and the rotation speed of the integrated tungsten steel stirring head is 1200r / min and the travel speed is 120r / min;

[0050] Step 3. Start the fricti...

Embodiment 3

[0055] The method of the present embodiment comprises the following steps:

[0056] Step 1. Install the integrated tungsten steel stirring head in the friction stir welding equipment; the integrated tungsten steel stirring head is an integrated part between the clamping end, the stirring needle and the shaft, and a concentric heat dissipation ring is arranged between the shafts. Such as Figure 2a and Figure 2b shown;

[0057] Step 2. Assemble and fix the two tungsten-boron-aluminum plates, and form the area to be welded between the opposite end faces of the two tungsten-boron-aluminum plates, obtain the components to be welded, and set the pressure sensor on the lower part of the components to be welded, and then set the integrated The pressure between the tungsten steel stirring head and the components to be welded is 15MPa, and the rotation speed of the integrated tungsten steel stirring head is 1000r / min and the travel speed is 90r / min;

[0058] Step 3. Start the frict...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com