Chromium mirror manufacturing process for automobile rearview mirror

A technology of automobile rearview mirror and technology, which is applied in vehicle parts, optical observation devices, transportation and packaging, etc., can solve the problems of easy film removal, environmental protection and high reflectivity of aluminum mirrors, so as to improve service life, safety, Strong anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] A chrome mirror mirror manufacturing process for automobile rearview mirrors, comprising the following steps:

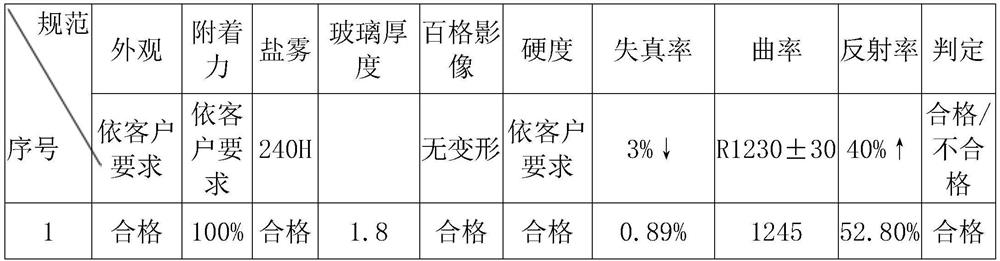

[0029] Step 1, slicing, using a white glass sheet with a thickness of 1.8mm, placing the white glass sheet at the cutting origin of the linear cutting machine, and the linear cutting machine cuts the white glass sheet into several lenses that meet the customer's specification size;

[0030] Step 2: Clean and inspect the front and back sides. The lens is placed in the washing machine, and the side of the lens side with a serrated structure is the front side;

[0031] Step 3, Bending, place the reverse side of the lens on a 300*400mm bending mold, put the bending mold into a U-shaped bending furnace, set the temperature of the U-shaped bending furnace to 715°C, and the speed to 26rpm;

[0032] Step 4, spotlight inspection, using spotlights to irradiate the lens;

[0033] Step 5, wash again, and place the lens in the washing machine;

[0034] Step 6, vapor depo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com