Preparation method and application of molybdenum phosphide/carbon fiber composite material

A composite material and carbon fiber technology, applied in the direction of phosphide, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of difficult removal of long-chain organic solvents, corrosiveness, phosphine toxicity, etc., to improve cycle stability, The effect of strong solubility and high redox activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Mix 0.5 mL of 70% phytic acid solution with 9.5 mL of DMF, add 0.5 g of phosphomolybdic acid and 1.5 g of polyvinylpyrrolidone, and fully stir to form a uniform spinning solution.

[0034] (2) Fill the spinning solution in step (1) into a syringe and connect it with a 0.7mm needle. Electrospinning is carried out by using an electrospinning device to obtain a phosphomolybdic acid / PVP composite fiber membrane. Among them, the aluminum foil-wrapped cylinder is used as the receiver, the negative high voltage is -2kV, the positive high voltage is 14kV, the receiving distance is 15cm, the relative humidity is 50%, and the ambient temperature is 50°C.

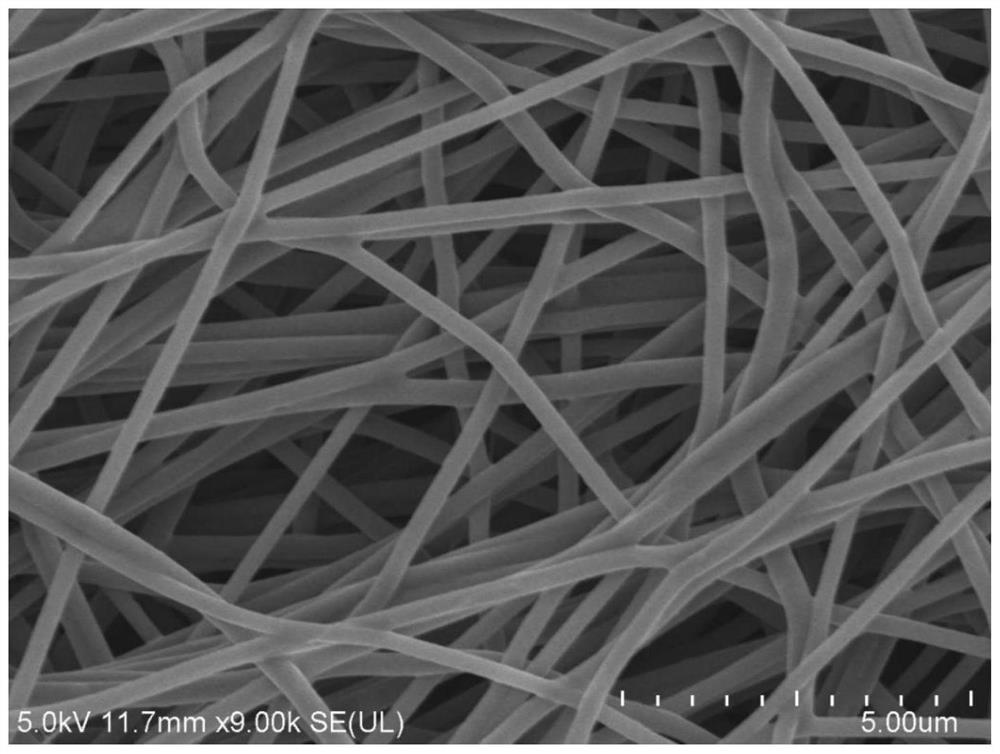

[0035] (3) Place the phosphomolybdic acid / PVP composite fiber membrane obtained in step (2) in a temperature-programmed muffle furnace, set the heating rate at 2°C / min, and react in an air atmosphere of 280°C for 2h. Then it was transferred to a tube furnace, and the temperature was raised to 700°C at a rate of 5°C / min und...

Embodiment 2

[0039] (1) Mix 1 mL of 70% phytic acid solution with 9 mL of DMF, add 0.5 g of phosphomolybdic acid and 0.6 g of polyacrylonitrile, and fully stir to form a uniform spinning solution.

[0040] (2) Fill the spinning solution in step (1) into a syringe and connect it with a 0.7mm needle. Electrospinning is carried out by using an electrospinning device to obtain a composite fiber membrane. Among them, the aluminum foil-wrapped cylinder is used as the receiver, the negative high voltage is -2kV, the positive high voltage is 14kV, the receiving distance is 15cm, the relative humidity is 50%, and the ambient temperature is 50°C.

[0041] (3) The composite fiber membrane obtained in step (2) was placed in a temperature-programmed muffle furnace with a heating rate of 2° C. / min, and reacted in an air atmosphere of 280° C. for 1 h. Then it was transferred to a tube furnace, and the temperature was raised to 800°C at a rate of 2°C / min under a nitrogen atmosphere and kept for 2h. After...

Embodiment 3

[0044] (1) Mix 0.5mL of 70% phytic acid solution with 9.5mL of DMF, add 0.25g of phosphomolybdic acid and 1.5g of polyvinylpyrrolidone, and fully stir to form a uniform spinning solution.

[0045](2) Fill the spinning solution in step (1) into a syringe and connect it with a 0.7mm needle. Electrospinning is carried out by using an electrospinning device to obtain a phosphomolybdic acid / PVP composite fiber membrane. Among them, the aluminum foil-wrapped cylinder is used as the receiver, the negative high voltage is -2kV, the positive high voltage is 14kV; the receiving distance is 15cm; the relative humidity is 40%, and the ambient temperature is 55°C.

[0046] (3) Place the phosphomolybdic acid / PVP composite fiber membrane obtained in step (2) in a temperature-programmed muffle furnace, set the heating rate at 2°C / min, and react in an air atmosphere of 230°C for 2h. transferred to a tube furnace under Ar / H 2 Atmosphere (volume ratio Ar:H 2 =0.95:0.05), the temperature was r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com