Lithium titanate composite negative electrode plate and preparation method thereof

A negative pole piece, lithium titanate technology, applied in the field of lithium ion batteries, can solve the problems affecting the rate performance, cycle performance and safety performance of the battery, insufficient performance of the gram capacity of lithium titanate, and increasing the probability of battery ignition, etc. Improved rate cycle performance, good redox activity, and improved rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

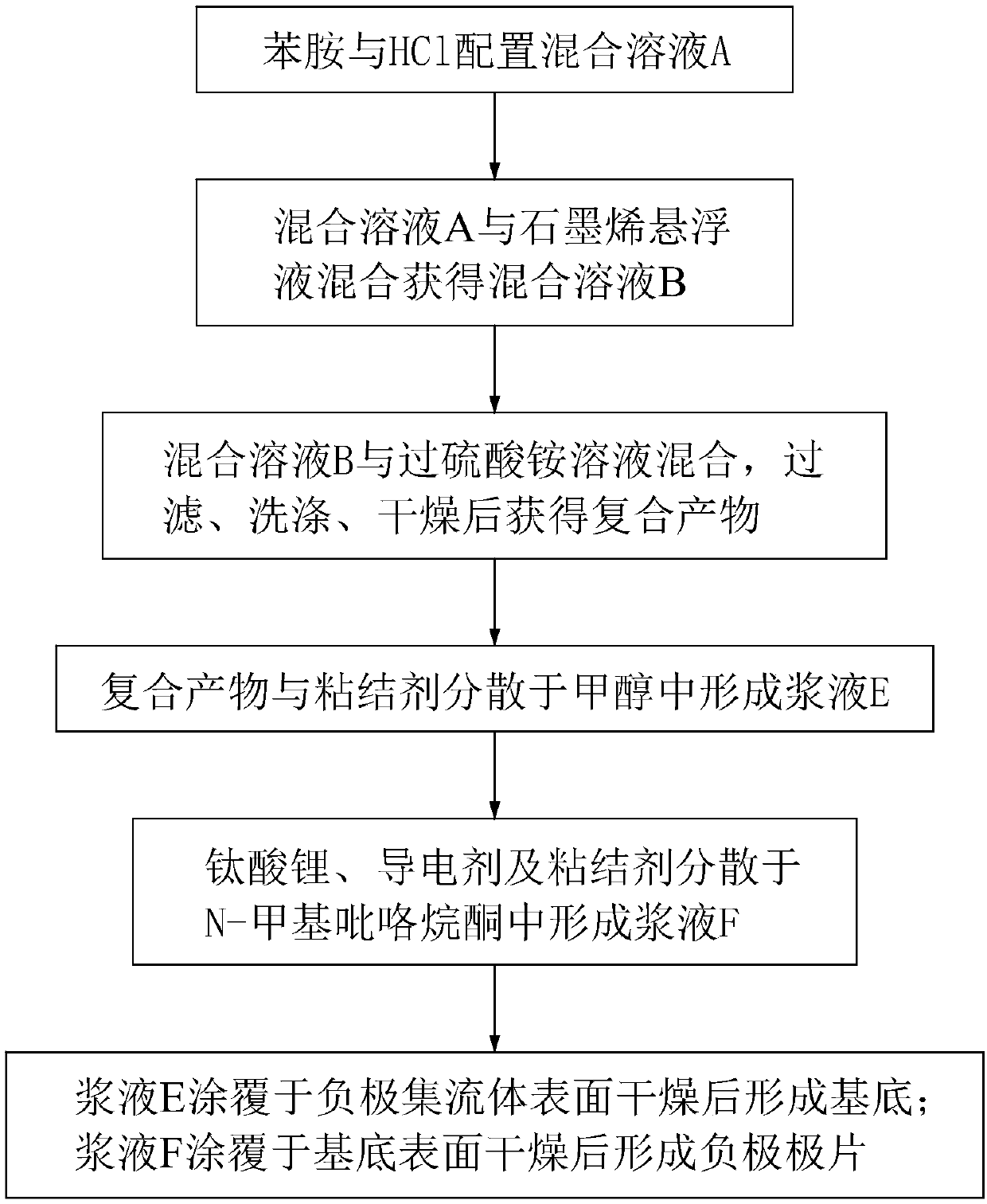

[0025] The present invention also provides a method for preparing a lithium titanate composite negative pole piece, comprising the following steps:

[0026] 1) Mixed solution A is configured with aniline and HCl and the concentrations of aniline and HCl in the mixed solution A are 0.2-0.5mol / L and 0.5-1mol / L respectively; graphene is used to configure a solute mass fraction of 1-4%. Graphene suspension; use ammonium persulfate to configure ammonium persulfate solution with a concentration of 0.1-0.25mol / L;

[0027] 2) The mixed solution A of equal volume is ultrasonically mixed with the graphene suspension for a period of time and then cooled in an ice-water bath to obtain the mixed solution B;

[0028] 3) Mixing an equal volume of the mixed solution B and the ammonium persulfate solution for a period of time and then filtering to obtain a filtrate, washing and drying the filtrate to obtain a composite product;

[0029] 4) Disperse the composite product and binder obtained in...

Embodiment 1

[0034] Adopt aniline and HCl to configure mixed solution A and the concentrations of aniline and HCl in the mixed solution A are 0.5mol / L and 1mol / L respectively; adopt graphene configuration solute mass fraction to be 4% graphene suspension; adopt persulfuric acid Ammonium is used to configure ammonium persulfate solution with a concentration of 0.25mol / L.

[0035] First, an equal volume of the mixed solution A was ultrasonically mixed with the graphene suspension for 60 minutes, and then cooled in an ice-water bath at about 2° C. for 3 minutes to obtain a mixed solution B. Then react an equal volume of the mixed solution B with the ammonium persulfate solution at a temperature of 0-4° C. for 6 h and then filter to obtain the filtrate. The filtrate is washed with distilled water and methanol respectively and heated at 80° C. The composite product was obtained by vacuum drying at a temperature of 12 h.

[0036] Next, the composite product and polyvinylidene fluoride were disp...

Embodiment 2

[0038] Adopt aniline and HCl configuration mixed solution A and the concentration of aniline and HCl in the described mixed solution A is respectively 0.2mol / L, 0.5mol / L; Adopt graphene configuration solute mass fraction to be the graphene suspension of 2%; Adopt process Ammonium sulfate is used to prepare ammonium persulfate solution with a concentration of 0.1mol / L.

[0039] Firstly, an equal volume of the mixed solution A and the graphene suspension were ultrasonically mixed for 30 minutes, and then cooled in an ice-water bath at about 2° C. for 2 minutes to obtain a mixed solution B. Then react an equal volume of the mixed solution B with the ammonium persulfate solution at a temperature of 0-4° C. for 4 h and then filter to obtain the filtrate. The filtrate is washed with distilled water and methanol respectively and heated at 70° C. The composite product was obtained by vacuum drying at a temperature of 15 h.

[0040] Next, the composite product and polyvinylidene fluorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com