A kind of graphene conductive ink and its preparation method and RFID label

A technology of RFID tags and conductive inks, applied in inks, instruments, computing, etc., can solve problems such as poor adhesion, affecting sensitivity and yield, curling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

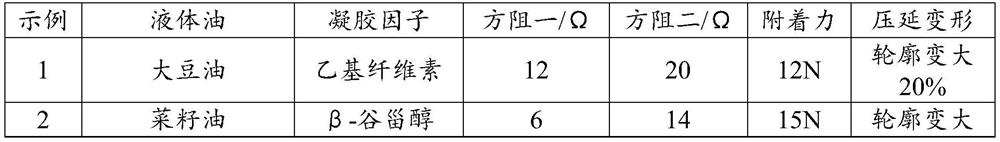

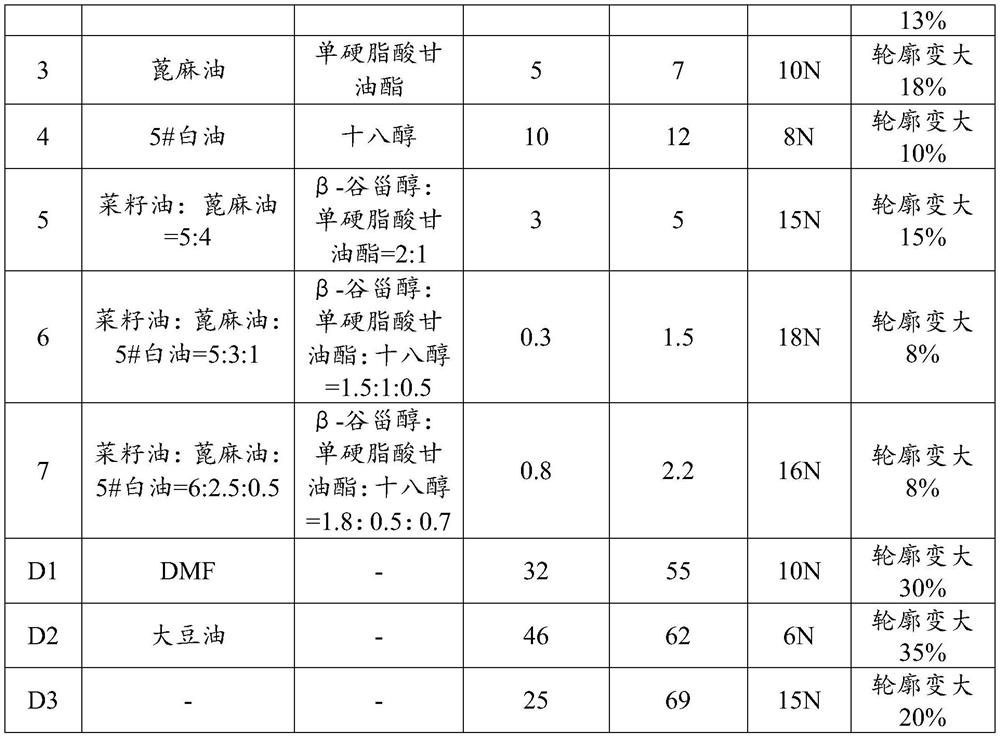

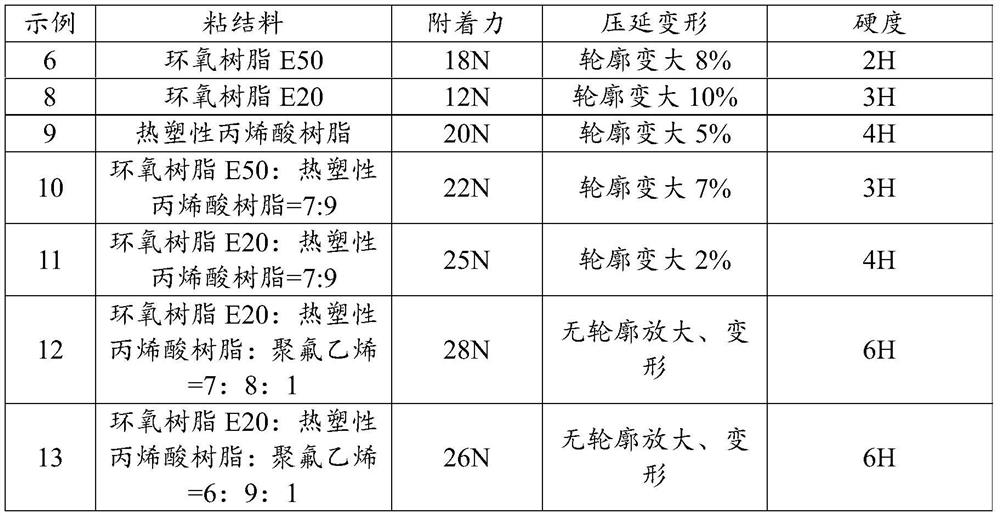

Examples

Embodiment 1

[0036] The present embodiment provides a kind of graphene conductive ink, and this graphene conductive ink is made up of the component of following parts by weight:

[0037] 27 parts of graphene nanosheet powder (average particle size 30 microns, sheet thickness 1-15 nanometers), 50 parts of liquid oil, 3 parts of gel factor, 16 parts of epoxy resin E50, 1-hydroxycycloethyl phenyl ketone 0.3 parts, 1.7 parts of hydroxyethyl acrylate, 1 part of polyether modified polysiloxane, 1 part of BYK-088.

[0038] The above-mentioned raw material components are prepared by the following method to obtain graphene conductive ink:

[0039] Step 1. Under the conditions of turning on ultrasonic dispersion and magnetic stirring at the same time, add the graphene nanosheet powder to the liquid oil in 8 times to obtain a mixed system, wherein the ultrasonic frequency is 20kHz, and the magnetic stirring rate is 1800r / min;

[0040] Step 2. After the addition, heat the mixed system to 100°C, add t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com