Preparation method of polyethylene modified high-strength composite alloy material

A polyethylene modification and composite alloy technology, which is applied in the field of polyethylene modified high-strength composite alloy material preparation, can solve problems such as poor effect of polyethylene materials, prevent the decline of physical and mechanical properties, improve molecular weight and relative viscosity, reduce The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

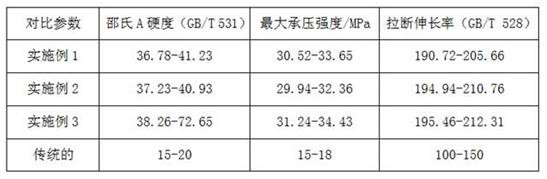

Examples

Embodiment 1

[0021] A method for preparing a polyethylene-modified high-strength composite alloy material, comprising the following raw materials in parts by weight: 130 parts of modified polyethylene masterbatch, 55 parts of grafted polyethylene resin, 35 parts of inorganic filler, and 4 parts of chain extender , 6 parts of coupling agent, 4 parts of compatibilizer and 2 parts of antioxidant 1076.

[0022] In this embodiment, the modified polyethylene masterbatch includes the following raw materials in parts by weight: 45 parts of polyethylene, 2 parts of quartz powder, 15 parts of polyvinyl chloride, and 5 parts of polycarbonate. The specific steps for making the modified polyethylene masterbatch The method is as follows: weighing each raw material in parts by weight for later use, melting and blending each raw material, extruding and granulating to obtain a modified polyethylene masterbatch.

[0023] Specifically, the nylon 6 resin is a resin with a melting point of 225°C.

[0024] It ...

Embodiment 2

[0033] A method for preparing a polyethylene-modified high-strength composite alloy material, comprising the following raw materials in parts by weight: 120 parts of modified polyethylene masterbatch, 60 parts of grafted polyethylene resin, 30 parts of inorganic filler, and 3 parts of chain extender , 5 parts of coupling agent, 3 parts of compatibilizer and 2 parts of antioxidant 1076.

[0034] In this embodiment, the modified polyethylene masterbatch includes the following raw materials in parts by weight: 40 parts of polyethylene, 2 parts of quartz powder, 20 parts of polyvinyl chloride, and 10 parts of polycarbonate. The specific steps for making the modified polyethylene masterbatch The method is as follows: weighing each raw material in parts by weight for later use, melting and blending each raw material, extruding and granulating to obtain a modified polyethylene masterbatch.

[0035] Specifically, the nylon 6 resin is a resin with a melting point of 225°C.

[0036] It...

Embodiment 3

[0045] A method for preparing a polyethylene-modified high-strength composite alloy material, comprising the following raw materials in parts by weight: 150 parts of modified polyethylene masterbatch, 50 parts of grafted polyethylene resin, 30 parts of inorganic filler, and 5 parts of chain extender , 8 parts of coupling agent, 5 parts of compatibilizer and 3 parts of antioxidant 1076.

[0046]In this embodiment, the modified polyethylene masterbatch includes the following raw materials in parts by weight: 50 parts of polyethylene, 1 part of quartz powder, 20 parts of polyvinyl chloride, and 3 parts of polycarbonate. The specific steps for making the modified polyethylene masterbatch The method is as follows: weighing each raw material in parts by weight for later use, melting and blending each raw material, extruding and granulating to obtain a modified polyethylene masterbatch.

[0047] Specifically, the nylon 6 resin is a resin with a melting point of 225°C.

[0048] It is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com