Thermotropic flame-retardant anti-dripping aromatic liquid crystal copolyester material and preparation method thereof

An anti-droplet and aromatic technology, applied in the field of polyester materials, can solve the problems of high melting point of phosphorus-based flame-retardant polyester, generation of molten droplets, generation of harmful gases, etc., achieve low melting processing temperature, simple preparation process, and widely used The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] A method for preparing a thermotropic flame-retardant and droplet-resistant aromatic liquid crystal copolyester material, comprising the steps of:

[0051] (1) According to the molar ratio of 10 ~ 40: 10 ~ 40: 80 ~ 20: 100 ~ 500: 2 ~ 8, the whole aromatic diphenol monomer, the whole aromatic diacid monomer, and the terminal carboxyl A and terminal AB type fully aromatic monomers of hydroxyl B, polyester particles, active end group compounds, and an appropriate amount of acetic anhydride (50-100% in molar weight relative to the total amount of hydroxyl groups in the raw material) and catalyst (the molar weight is the total molar weight of raw materials) 0.1-0.5% of the amount) into the reactor; under the protection of inert gas, the acetylation reaction is carried out at 120-150° C. for 30-60 minutes.

[0052] (2) Raise the temperature to 300-340° C. at a heating rate of 0.5-1.5° C. / min, and transesterify for 1-3 hours.

[0053] (3) Further reacting for 10-30 minutes un...

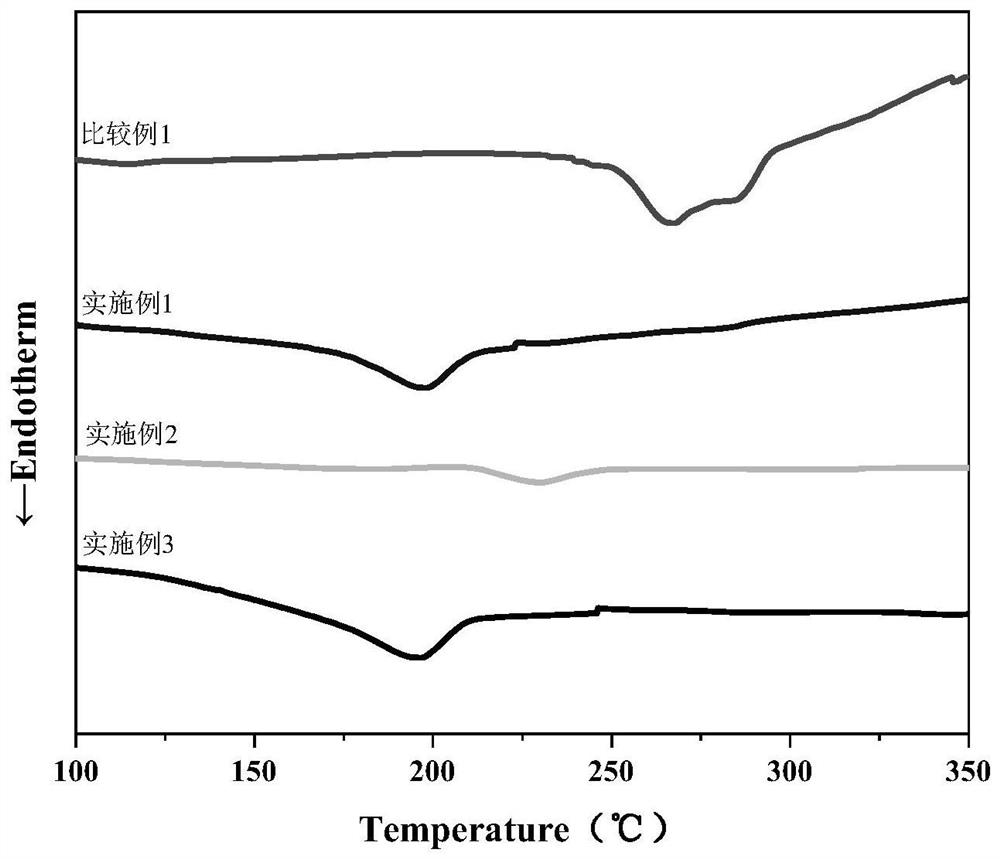

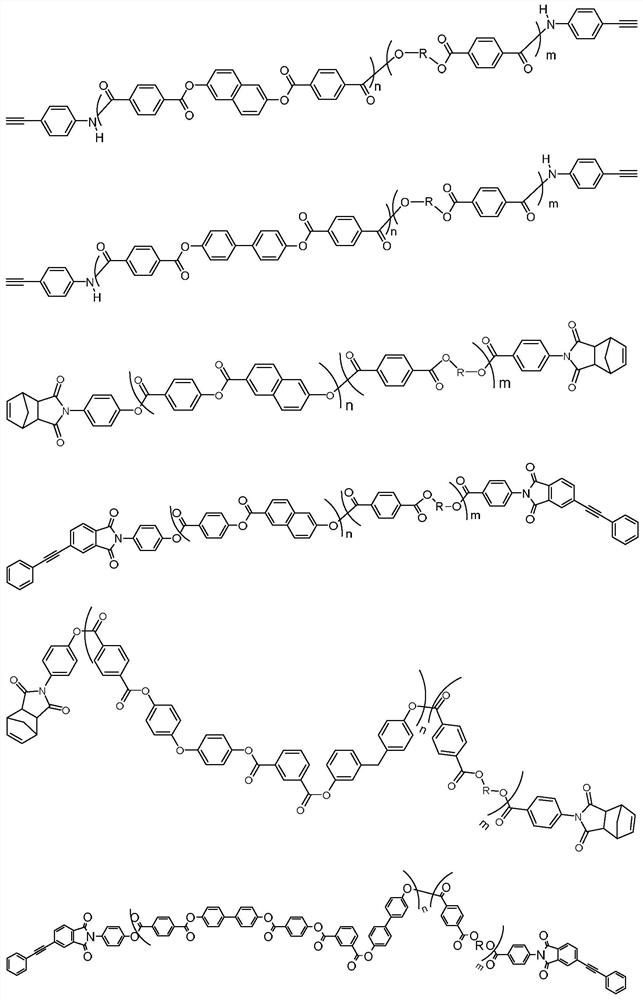

Embodiment 1

[0064] Preparation of thermotropic flame retardant anti-droplet aromatic liquid crystal copolyester material: add 4 in a 250 ml three-neck round bottom flask at a molar ratio of 100:80:20:800:1000:80:80:1800:4, 4'-dihydroxybiphenyl, terephthalic acid, 2,6-naphthalene dicarboxylic acid, p-hydroxybenzoic acid, PET particles, N-(3-carboxyphenyl)-4-phenylethynylphthaloyl Amine, N-(3-hydroxyphenyl)-4-phenylethynylphthalimide, and acetic anhydride and potassium acetate. The flask was fitted with a sealed glass paddle stirrer, a nitrogen inlet tube and an insulated distillation head. A moderate nitrogen flow was introduced, and the reaction mixture was acetylated at 120°C for 30 minutes in a quicksand bath, and then the temperature was raised to 340°C at a rate of 1.5°C / min for 1 hour of transesterification. At this point, the reaction system was slowly evacuated to a vacuum degree of 1 mbar and the temperature was set to 300° C. for 10 min. The opaque melt was cooled to room tempe...

Embodiment 2

[0066] Preparation of thermotropic flame retardant and anti-droplet aromatic liquid crystal copolyester material: Add p-benzene in a 250 ml three-neck round bottom flask at a molar ratio of 200:160:40:600:5000:20:20:1200:36 Diphenol, terephthalic acid, 1,7-naphthalene dicarboxylic acid, 6-hydroxy-2-naphthoic acid, PBT particles, 3-ethynylaniline, 2-(3-ethynylphenyl)-1,3-di Oxyisoindole-5-carboxylic acid, as well as acetic anhydride and zinc acetate. The flask was fitted with a sealed glass paddle stirrer, a nitrogen inlet tube and an insulated distillation head. A moderate nitrogen flow was introduced, and the reaction mixture was acetylated at 150°C for 60 minutes in a quicksand bath, and then the temperature was raised to 320°C at a rate of 1.5°C / min for 3 hours of transesterification. At this point, the reaction system was slowly evacuated to a vacuum degree of 3 mbar and the temperature was set to 320° C. for 30 min. The opaque melt was cooled to room temperature and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com