Low-alloy high-strength corrosion-resistant steel bar and preparation method thereof

A low-alloy, high-strength, corrosion-resistant technology, applied in the field of steel preparation, can solve the problems of low content of steel alloy elements, increase the difficulty of production, and difficulty in obtaining, etc., to achieve improved mechanical properties, improved grain boundary corrosion resistance, and low construction requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

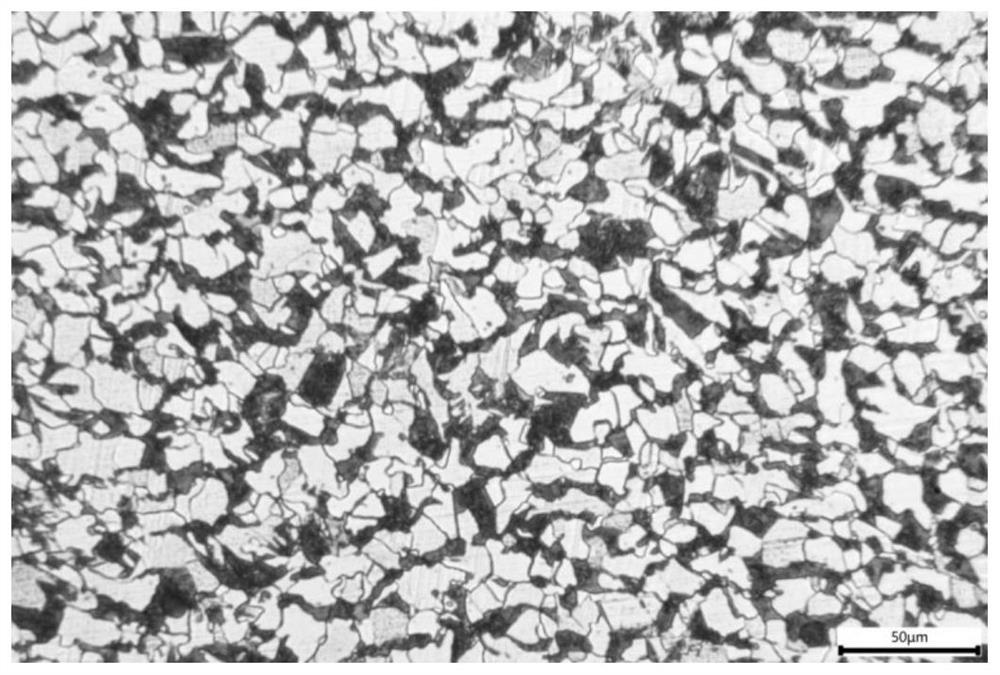

Image

Examples

Embodiment Construction

[0038] The four embodiments and comparative examples are described in detail below.

[0039] Table 1 is the chemical composition table of 4 examples and comparative examples.

[0040] Table 2 is the performance test table of 4 examples and comparative examples.

[0041] The 4 embodiments of the present invention are all in accordance with the following production steps

[0042] (1) Converter smelting: when the temperature of molten steel at the end of the converter reaches 1620-1680 °C and P<0.035%, the steel can be tapped. When tapping, it is required that the tapping port is in good condition, the steel flow is round, and the tapping process is blown with Ar stirring and tapping. The time is greater than 3min. Use silicon-manganese alloy, ferrosilicon, vanadium ferroalloy (or vanadium-nitrogen alloy), medium carbon ferrochromium (or low carbon ferrochromium) and aluminum block (or aluminum ferro) with less than 1% carbon for deoxidation and alloying, and tap steel to From...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com