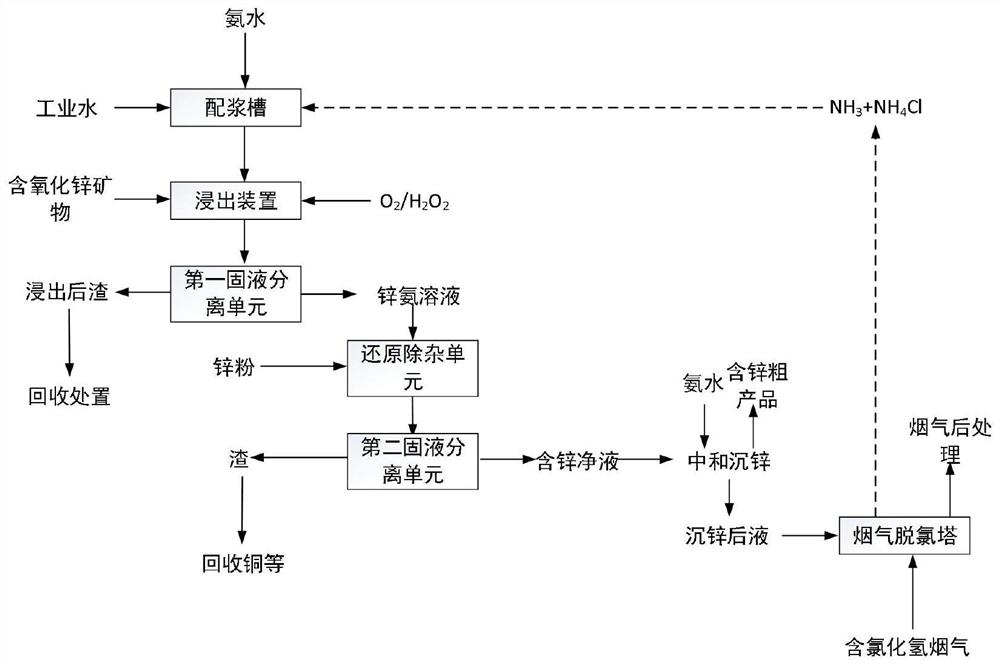

Method for dechlorinating flue gas by efficiently leaching zinc-containing minerals and recycling solution

A solution and mineral technology, which is applied in the field of flue gas dechlorination, efficient leaching of zinc-containing minerals and solution recycling, can solve problems such as strong corrosion, corrosion of equipment materials, and difficulty in resource utilization of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The ore containing zinc oxide used in this example comes from a company in Yunnan. The main components in the ore are as follows in terms of mass percentage: Zn 30.50%, Fe 4.6%, Pb 2.5%, Ca 2.1%, S 0.4%, K 0.28%, Cu 0.05 %; at 1000mg / m 3 HCl cylinder gas, purity 95% N 2 Cylinder gas, 99% O 2 Precisely prepared by mass flowmeter to simulate flue gas containing hydrogen chloride, where O 2 Volume concentration is 16.5%, HCl concentration is 100mg / m 3 , the flue gas temperature is 55°C.

[0066] A method for efficient leaching of zinc-containing minerals and solution resource utilization for flue gas dechlorination, the specific steps are as follows:

[0067] (1) Using a three-necked Erlenmeyer flask as a wet leaching device for zinc-containing minerals, add 25 mL of ammonia water and 75 mL of water with a mass fraction of 28%, stir magnetically for 5 minutes, and mix evenly to obtain a leaching agent;

[0068] (2) Adding 10 g of zinc oxide-containing ore with an ave...

Embodiment 2

[0074] The ore containing zinc oxide used in this example comes from a company in Yunnan. The main components in the ore are as follows in terms of mass percentage: Zn 54.50%, Fe 3.6%, Pb 4.5%, Ca 0.8%, S 0.4%, K 0.28%, Cu 0.07 %; at 1000mg / m 3 HCl cylinder gas, purity 95% N 2 Cylinder gas, 99% O 2 Precisely prepared by mass flowmeter to simulate flue gas containing hydrogen chloride, where O 2 Volume concentration is 16.5%, HCl concentration is 200mg / m 3 , the flue gas temperature is 55°C.

[0075] A method for efficient leaching of zinc-containing minerals and solution resource utilization for flue gas dechlorination, the specific steps are as follows:

[0076] (1) Use a three-necked Erlenmeyer flask as a zinc-containing mineral wet leaching device, add 50 mL of ammonia water and 50 mL of water with a mass fraction of 28%, stir magnetically for 5 minutes, and mix evenly to obtain a leaching agent;

[0077] (2) Add 20g of zinc oxide-containing ore with an average partic...

Embodiment 3

[0083] The ore containing zinc oxide used in this example comes from a company in Yunnan. The main components in the ore are as follows in terms of mass percentage: Zn 30.50%, Fe 4.6%, Pb 2.5%, Ca 2.1%, S 0.4%, K 0.28%, Cu 0.05 %; at 1000mg / m 3 HCl cylinder gas, purity 95% N 2 Cylinder gas, 99% O 2 Precisely prepared by mass flowmeter to simulate flue gas containing hydrogen chloride, where O 2 Volume concentration is 15.5%, HCl concentration is 300mg / m 3 , the flue gas temperature is 65°C.

[0084] A method for efficient leaching of zinc-containing minerals and solution resource utilization for flue gas dechlorination, the specific steps are as follows:

[0085] (1) Use a three-necked Erlenmeyer flask as a zinc-containing mineral wet leaching device, add 50 mL of ammonia water and 50 mL of water with a mass fraction of 28%, stir magnetically for 5 minutes, and mix evenly to obtain a leaching agent;

[0086] (2) Add 33.3g of zinc oxide-containing ore with an average part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com