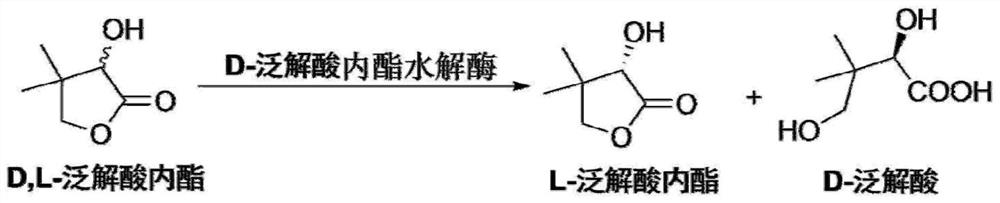

D-pantolactone hydrolase, producing bacteria and genetically engineered bacteria thereof, and applications of D-pantolactone hydrolase and producing bacteria and genetically engineered bacteria

A technology of pantolactone and genetically engineered bacteria, applied in the field of D-pantolactone hydrolase and its producing bacteria, can solve the problem of few microorganisms producing lactone hydrolase and achieve high-efficiency expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Screening of D-pantolactone hydrolase-producing microorganisms (ie: D-pantolactone hydrolase-producing bacteria or Thielavia sp.zmu20201 microorganisms)

[0028] Preparation of PDA solid medium: take 200g of potatoes, wash and peel them, cut into pieces, add 1000mL of water and boil for 30 minutes, collect the filtrate through gauze filtration, replenish water to 1L, then add 20g of glucose and 15g of agar, pH neutral, after After high-pressure cultivation, a fixed medium was prepared.

[0029] Preparation of fermentation liquid medium: peptone 10g / L, yeast powder 5g / L, glycerol 10g / L, corn steep liquor 5g / L, neutral pH, cooled after high-pressure cultivation for later use.

[0030] Take 10-20g of the collected soil sample, add 100mL of sterile water, shake for 3 minutes, and then let it stand for 10 minutes; take the supernatant bacterial solution to dilute and apply, and dilute the supernatant to evenly apply to PDA medium; solid plate substrate Place in a...

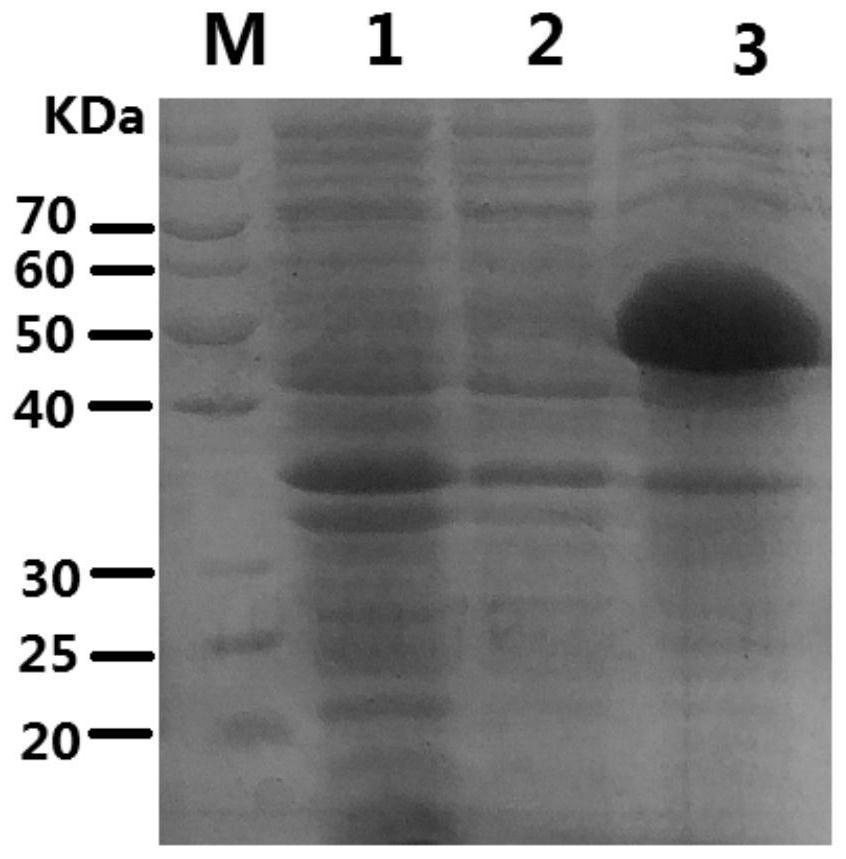

Embodiment 2

[0036] Example 2: Fermentation of D-pantolactone hydrolase producing bacteria Thielavia sp.zmu20201 to produce enzyme

[0037] Strain activation culture: Pick an appropriate amount of Thielaviasp. zmu20201 microorganisms from the glycerol-preserved bacterial liquid or refrigerated seed slant and streak it on the potato dextrose agar (PDA) medium, and place the streaked eggplant bottle slant medium at a constant temperature of 28-35°C for cultivation Box, cultivated for 2-3 days.

[0038] Seed liquid culture: The liquid seed medium preparation scheme is as follows: peptone 10-20g / L, yeast extract 10-20g / L, sucrose 10-20g / L, corn steep liquor 1-5g / L, pH 6.5-7.5, extinguished at 115°C After inoculation for 30 minutes, cool down for later use; inoculate the activated seeds into a 250mL shaker, fill with 50-100mL liquid seed medium, and cultivate in a constant temperature shaker at 28-35°C for 48-60 hours.

[0039] Fermentation enzyme production culture: fermentation enzyme produc...

Embodiment 3

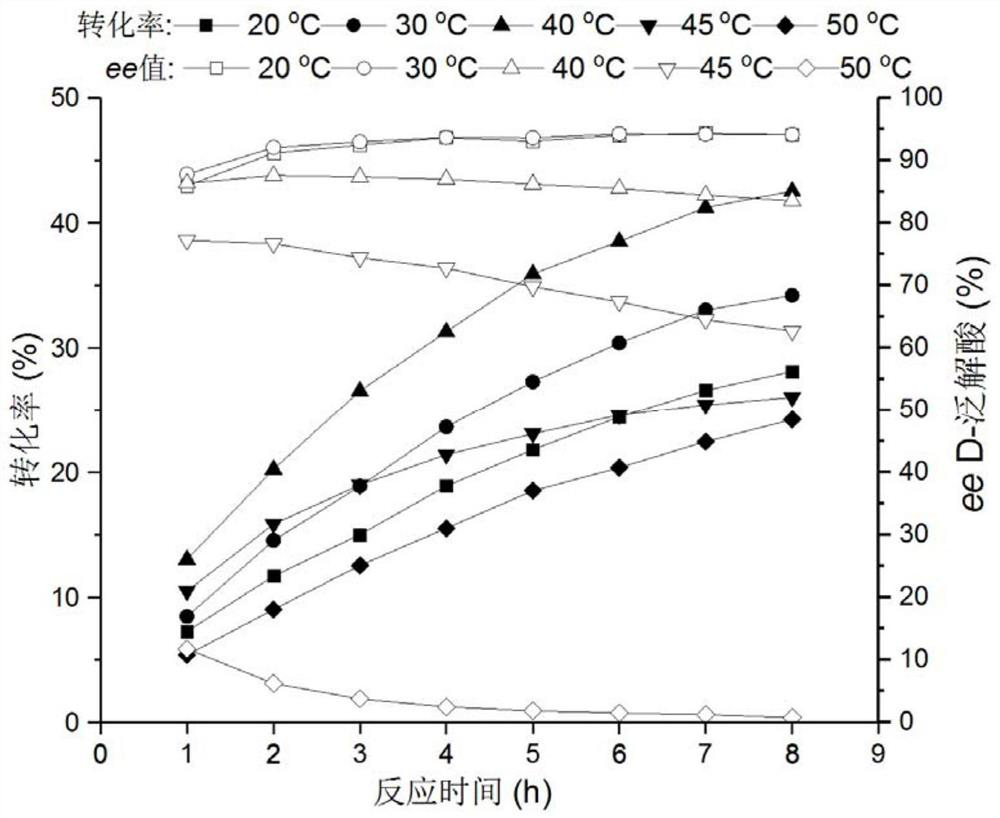

[0041] Example 3: D-pantoate lactone hydrolase-producing bacteria Thielavia sp.zmu20201 fermentation bacteria biotransformation to prepare D-pantoate

[0042] Using the bacteria collected from Thielavia sp.zmu20201 microbial fermentation as a biocatalyst, the hydrolysis experiment of D, L-pantolactone was carried out. The biocatalytic system is as follows: Dissolve 2g of D,L-pantolactone in 16mL of water, make up to 20mL with water, stir well and quickly add it into a 100mL three-necked bottle with a magnetic stirring speed of 200rpm; then add fermentation The collected wet mycelium 1g, starts the hydrolysis reaction, and the reaction temperature is controlled at about 30°C. The pH of the reaction was detected online with a pH meter, and the reaction pH was controlled at 7.0 ± 0.2 by adding 5% ammonia water. The reaction time was about 14 hours. When the reaction pH was basically stable, the reaction was terminated. The reaction process is shown in Table 2.

[0043] Table 2 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com