Large-size planar substrate coating method and device based on linear magnetron sputtering target gun

A flat substrate, magnetron sputtering technology, used in sputtering coating, vacuum evaporation coating, ion implantation coating and other directions, can solve the problems of poor uniformity of coating thickness, limited size of prepared samples, etc The uniformity is better than the effect of improving the uniformity of coating thickness and good coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

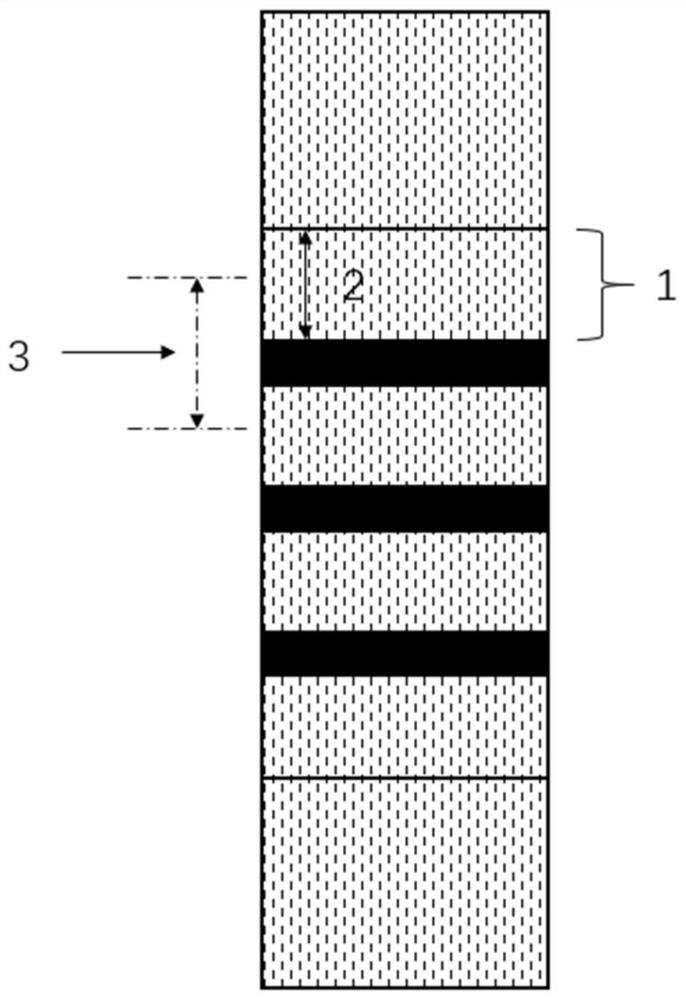

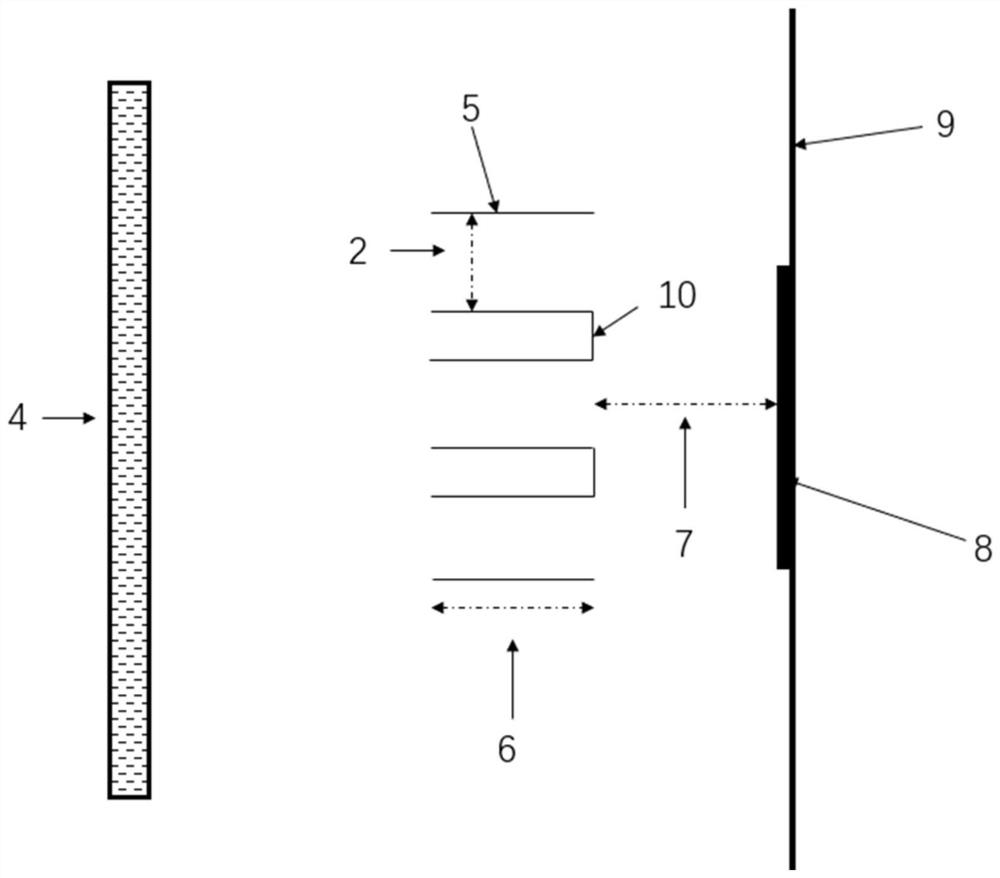

[0036] The target gun is a linear magnetron sputtering target gun, and the size of the sputtering surface of the target gun is 38mm×508mm. The unique shape and larger size of the target gun will cause some particles to be incident at a larger angle, resulting in poor coating quality and poor thickness uniformity on large flat substrates. To solve this technical problem, the present invention provides a large-size planar substrate coating method based on a linear magnetron sputtering target gun. While controlling the coating quality of the sputtering target gun, the uniformity of the coating thickness on the large-size flat substrate is improved. In this embodiment, the sample holder is 600 mm long and 250 mm wide; the target distance is set to 100 mm.

[0037] Since the sputtering uniform area of the target is limited, the method is suitable for large-size planar substrates with a length of 100 mm to 450 mm and a width of less than 200 mm. In this embodiment, the sample is...

Embodiment 2

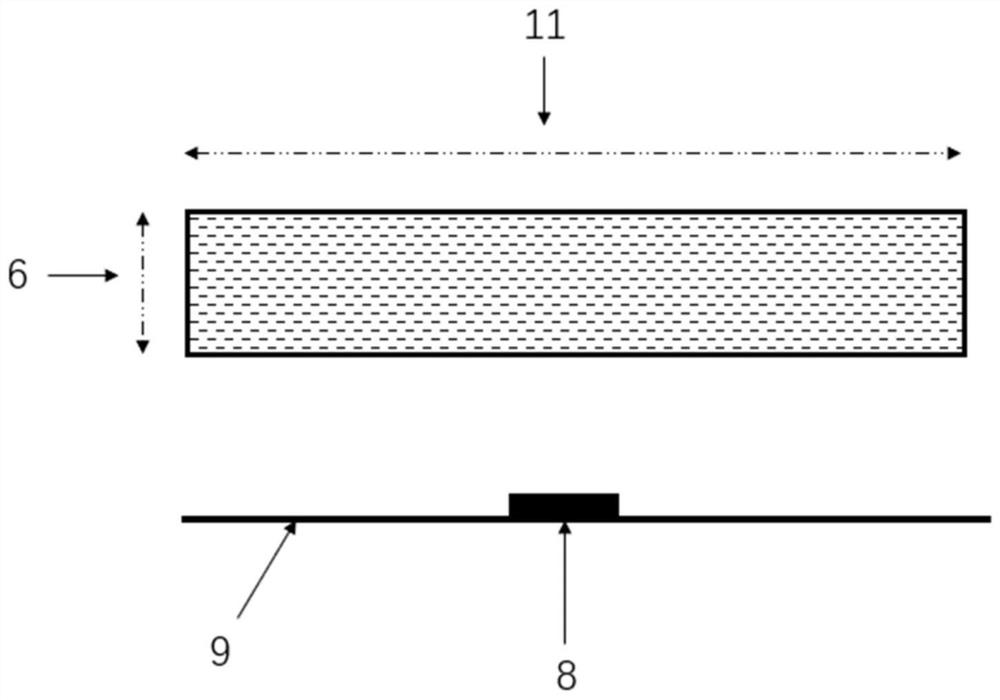

[0047] In this embodiment, a large-size planar substrate coating device based on a linear magnetron sputtering target gun includes a linear magnetron sputtering target gun, a sample holder, and several groups of two-by-two partition plates. The plane where the sample holder is located Parallel to the plane where the linear magnetron sputtering target gun is located, the partition plate is installed in the horizontal direction perpendicular to the plane where the sample holder is located; when coating, the large-size flat substrate is installed at the center of the sample holder, and the partition plate is located where the substrate is located. Above the plane, the distance between the middle lines of two adjacent sets of partitions is obtained based on the simulation of the film deposition thickness distribution. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com