Synechocystis PCC6803 strain for producing alkaline pectate lyase and construction method of synechocystis PCC6803 strain

A PCC6803, pectin lyase technology, applied in microorganism-based methods, lyases, carbon-oxygen lyases, etc., can solve the problems of energy conversion and unreasonable economics, limiting the efficiency and feasibility of bioenergy conversion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

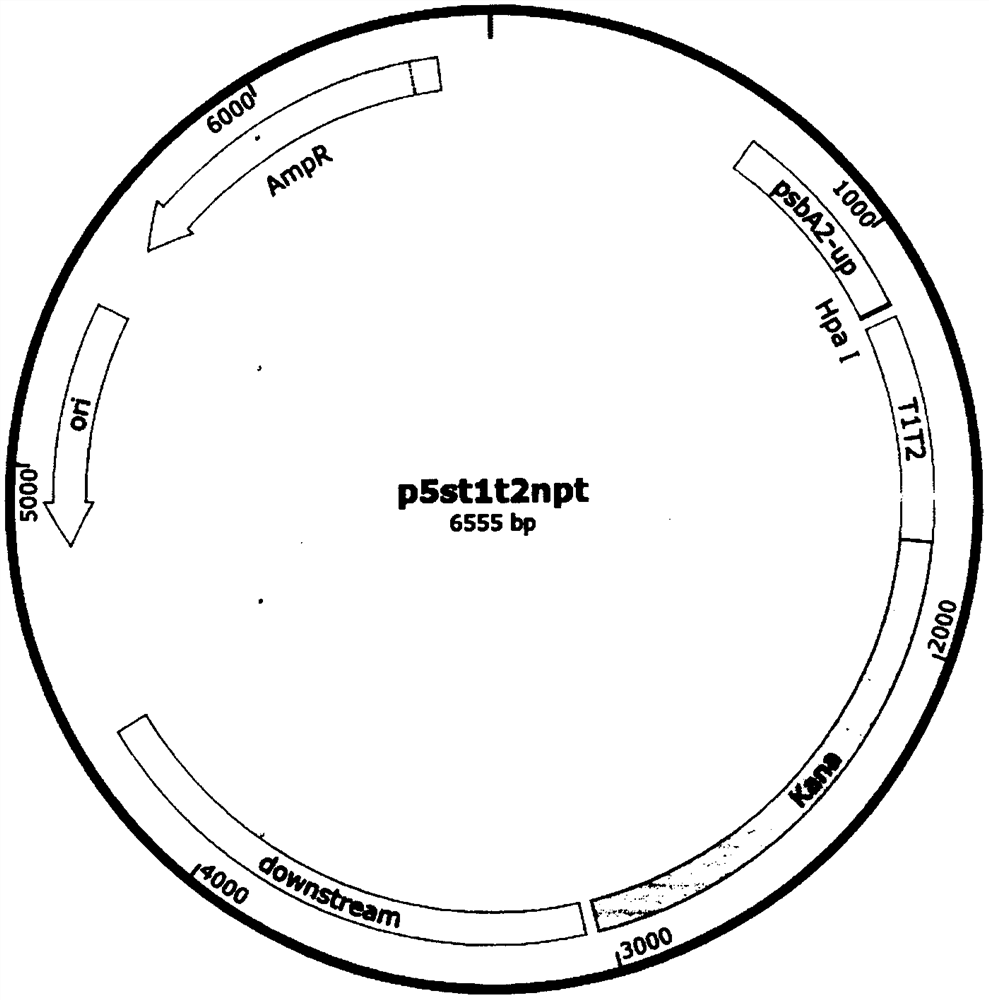

[0026]Construction of p5st1t2npt plasmid

[0027]Using SEQ ID NO: 4 and SEQ ID NO: 5 in the sequence list as the upstream and downstream primers, and using the E. coli with GenBank accession number U02439.1 as the template, the E. coli terminator T1T2 gene fragment was obtained by PCR amplification technology. The sequence is shown in SEQ ID NO: 6 in the sequence listing. The amplification program is: 94°C, 3min; 98°C, 10s, 55°C, 15s, 72°C, 40s, 30 cycles; 72°C, 5min, 4°C, 10min. After the PCR reaction, the gel is cut and recovered by electrophoresis. The obtained E. coli terminator T1T2 gene fragment was subjected to double digestion with PStI and BamHI, ligated with the pBluescript SK plasmid after the same double digestion with T4 ligase, transformed into E. coli DH5α, positive clones were screened and sequenced to obtain plasmid pBluescript SKT1T2. The digestion system is: DNA 3μL, endonuclease 1μL, 10×Buffer 1μL, ddH2O 4μL, digestion temperature is 30℃, digestion time is 2h. Using...

Embodiment 2

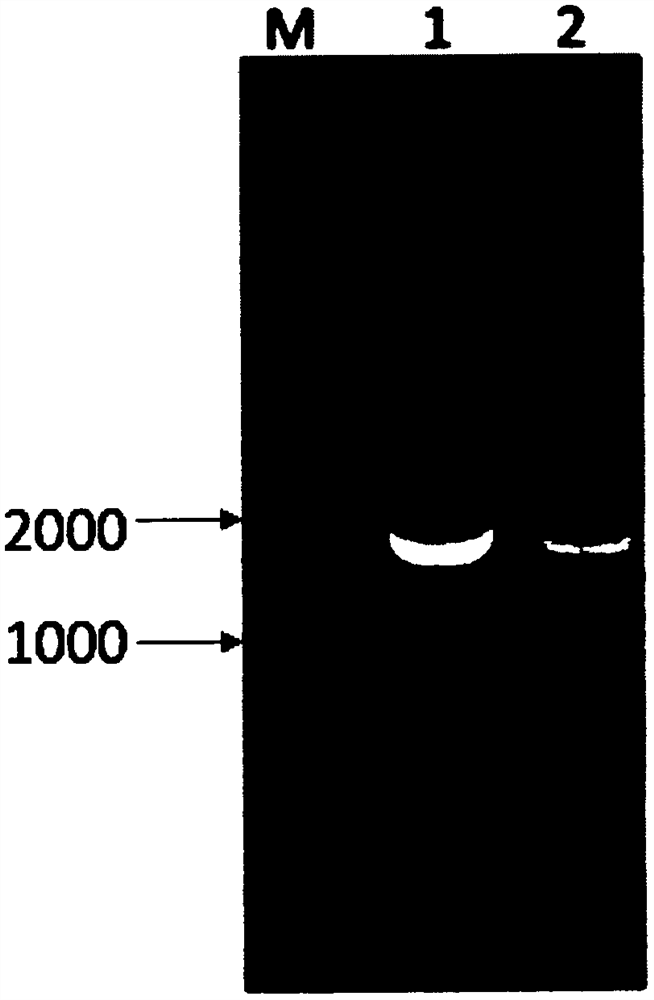

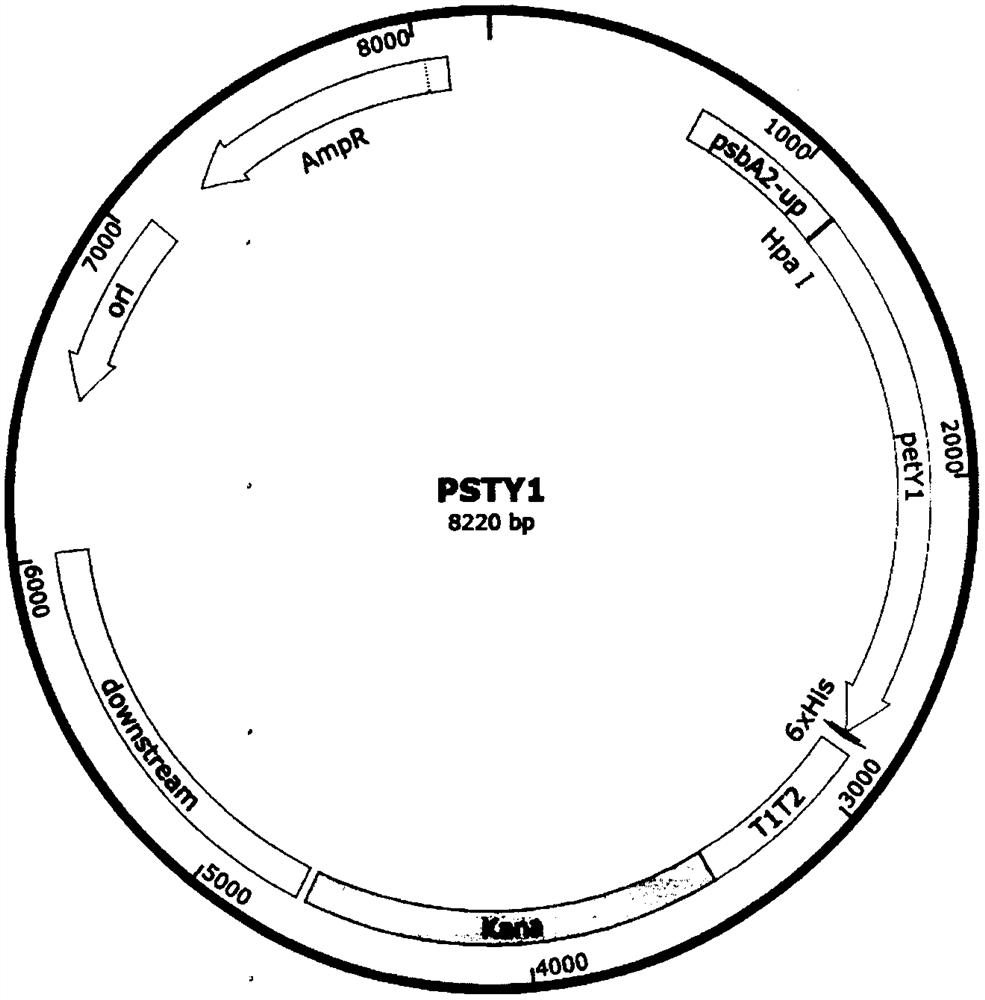

[0030]Construction of recombinant expression vector PSTY1

[0031]Using SEQ ID NO: 10 and SEQ ID NO: 11 in the sequence list as the upstream and downstream primers, and the corresponding gene sequence of Klebsiella sp. Y1 in the GenBank database as the template, the basicity was obtained by PCR amplification technology The sequence of the pectin lyase gene fragment pety1 is shown in SEQ ID NO: 12 in the sequence table. The amplification program is: 94°C, 3min; 98°C, 10s, 55°C, 15s, 72°C, 2min, 30 cycles; 72°C, 5min, 4°C, 10min. The plasmid p5st1t2npt was cut with restriction enzyme HpaI to obtain the p5st1t2npt vector fragment. After phosphorylation, the vector fragment was subjected to homologous recombination with the pety1 gene fragment under the action of recombinase, transformed into E. coli DH5α, and positive clones were screened and sequenced , The recombinant expression vector PSTY1 was obtained. The digestion system is: DNA 3μL, endonuclease 2μL, 10×Buffer 1μL, ddH2O 4μL, dige...

Embodiment 3

[0033]Obtaining and expanding culture of Synechocystis PCC6803 genetically engineered strain PSTY1

[0034]The recombinant expression vector PSTY1 was recombined into the Synechocystis PCC6803 genome by the natural transformation method, and the engineered strain PSTY1 was obtained after antibiotic screening. The specific steps are: take the logarithmic culture period (OD730=0.6) Synechocystis PCC680 350ml centrifuged at 5000r / min for 10min at room temperature, discard the supernatant, add fresh BG-11 liquid medium and wash once, add fresh BG-11 liquid medium to the final concentration OD730= 4.8, and immediately used for conversion. Divide the collected algae liquid into 1.5ml EP tubes (400ul per tube), add 10ug PSTY1 plasmid to each tube, and incubate under low light conditions with light for 6 hours, shaking once during the period. The mixture was applied to a BG11 plate medium containing kanamycin resistance (50 μg / mL), and transformants were visible in about 10 days. The grown alg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com