Preparation of super-hydrophobic surface composite film and application of super-hydrophobic surface composite film in metal corrosion protection

A super-hydrophobic surface and metal corrosion technology, which is applied to the surface coating liquid device, pretreatment surface, anti-corrosion coating, etc., can solve the problems of hindering the diffusion of corrosive media, insufficient wear resistance, etc., to slow down the particle transmission rate, High conductivity, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

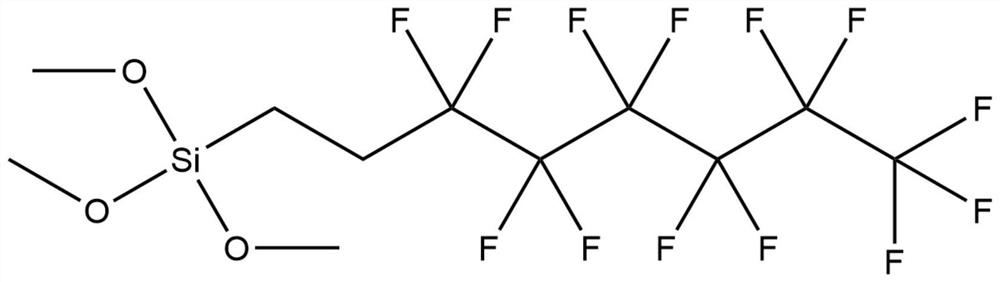

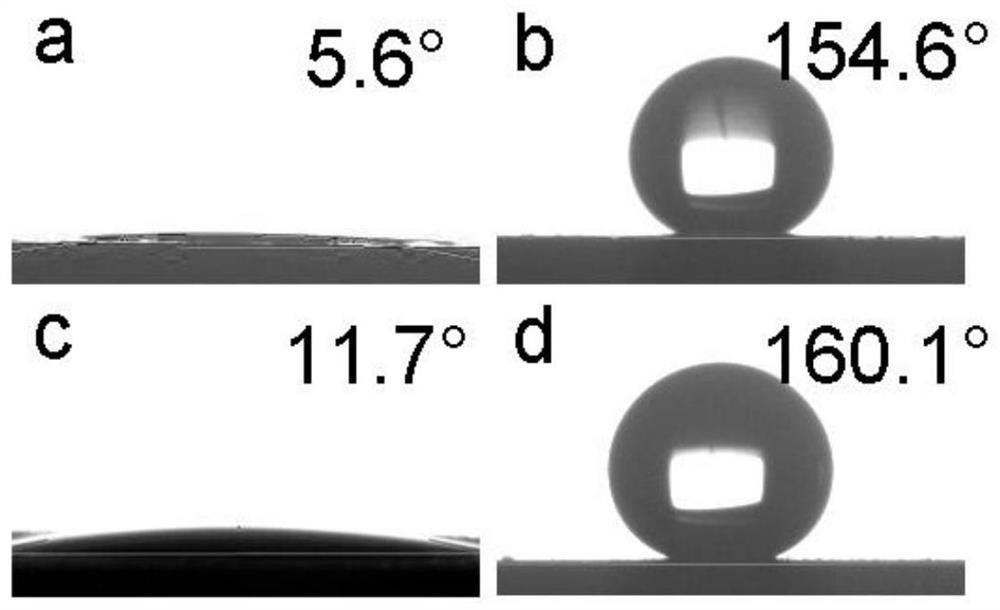

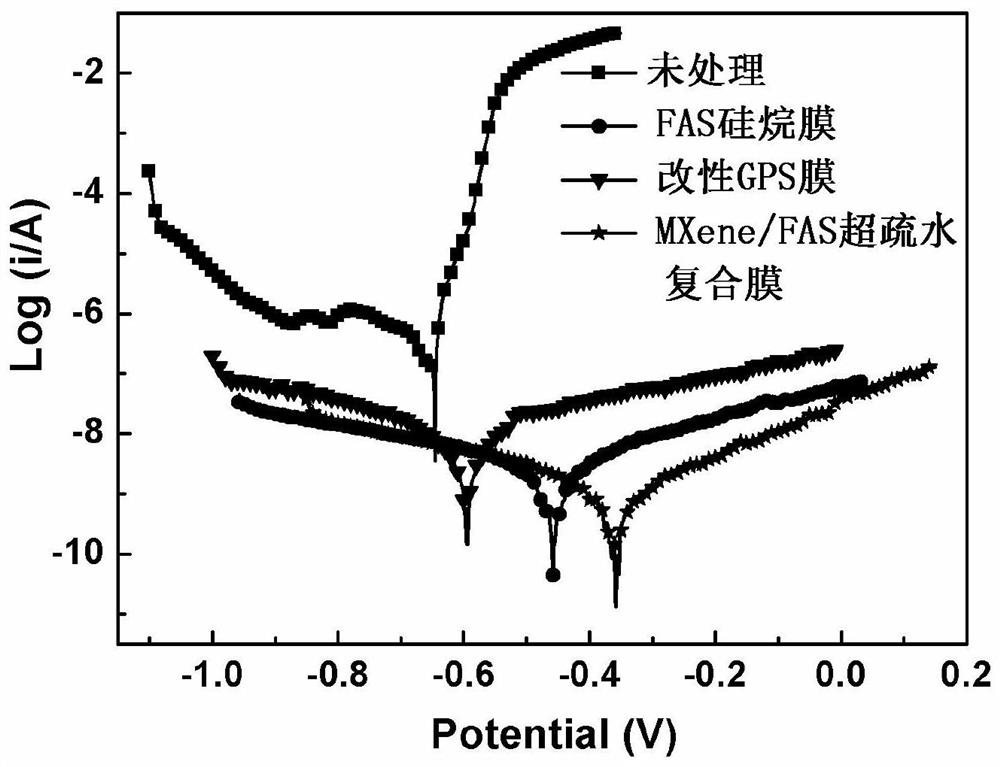

[0057] The size of the aluminum alloy is cut into 10mm×10mm×1mm, and it is polished step by step with 800#, 1000#, 1500#, 2000# water-grinding sandpaper, and then ultrasonically degreased with acetone and ethanol for 10 minutes respectively; the metal sample is acid-etched, Etch at room temperature for 6 minutes, rinse with deionized water, and boil in boiling water for 15 minutes, take it out and dry it, and dry it at 80°C for 1 hour for use. Prepare 5% concentration containing SiO 2 The γ-GPS silane solution of nanoparticles, wherein γ-GPS / water / ethanol is 5 / 15 / 80 (v / v / v), the pH is adjusted to 4.5 with acetic acid, and SiO 2 Nanoparticles (concentration: 50mg / mL) were ultrasonically hydrolyzed at 35°C for 2h, and used as the film-forming solution in the first step. Prepare a 5% concentration of FAS perfluorosilane solution, mix MXene with the above silane solution, and stir evenly to obtain a MXene / FAS mixed solution. The concentration of MXene is 0.8 mg / mL, adjust the pH ...

Embodiment 2

[0059] First prepare a 5% concentration of FAS perfluorosilane solution, mix MXene with the above silane solution, and stir evenly to obtain a mixed solution of MXene / FAS. The concentration of MXene is 0.8 mg / mL, adjust the pH to 4.5 with acetic acid, and ultrasonically hydrolyze at 35 °C 1-2h, the obtained MXene / FAS hydrolyzate. The size of the aluminum alloy is cut into 10mm×10mm×1mm, and it is polished step by step with 800#, 1000#, 1500#, 2000# water-grinding sandpaper, and then ultrasonically degreased with acetone and ethanol for 10 minutes respectively; the metal sample is acid-etched , etched at room temperature for 6 minutes, rinsed with deionized water, and boiled in boiling water for 15 minutes, taken out and dried at 80°C for 1 hour, and then the solution prepared above was spin-coated on the surface of the pretreated aluminum alloy to form a film. The rotation speed is 3000rmp, the time is 30s, and the continuous operation is performed twice, and then put into a 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com