Solvent-free quick-curing reaction type waterproof coating and preparation method thereof as well as roll-coating laminated waterproof construction system and construction method thereof

A fast-curing, waterproof coating technology, applied in polyether coatings, building structures, infrastructure engineering, etc., can solve the problems of drying speed, low solid content of water-emulsion coatings, high toxicity, etc., and achieve strong bonding strength , Improve the effect of UV stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

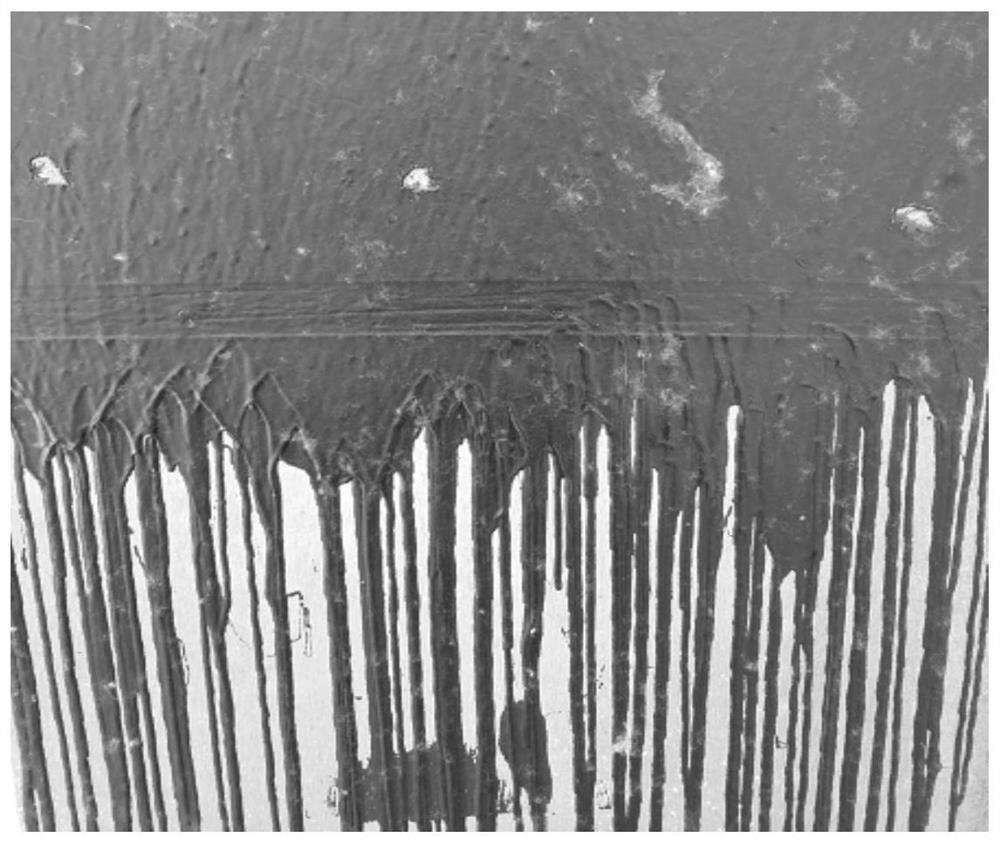

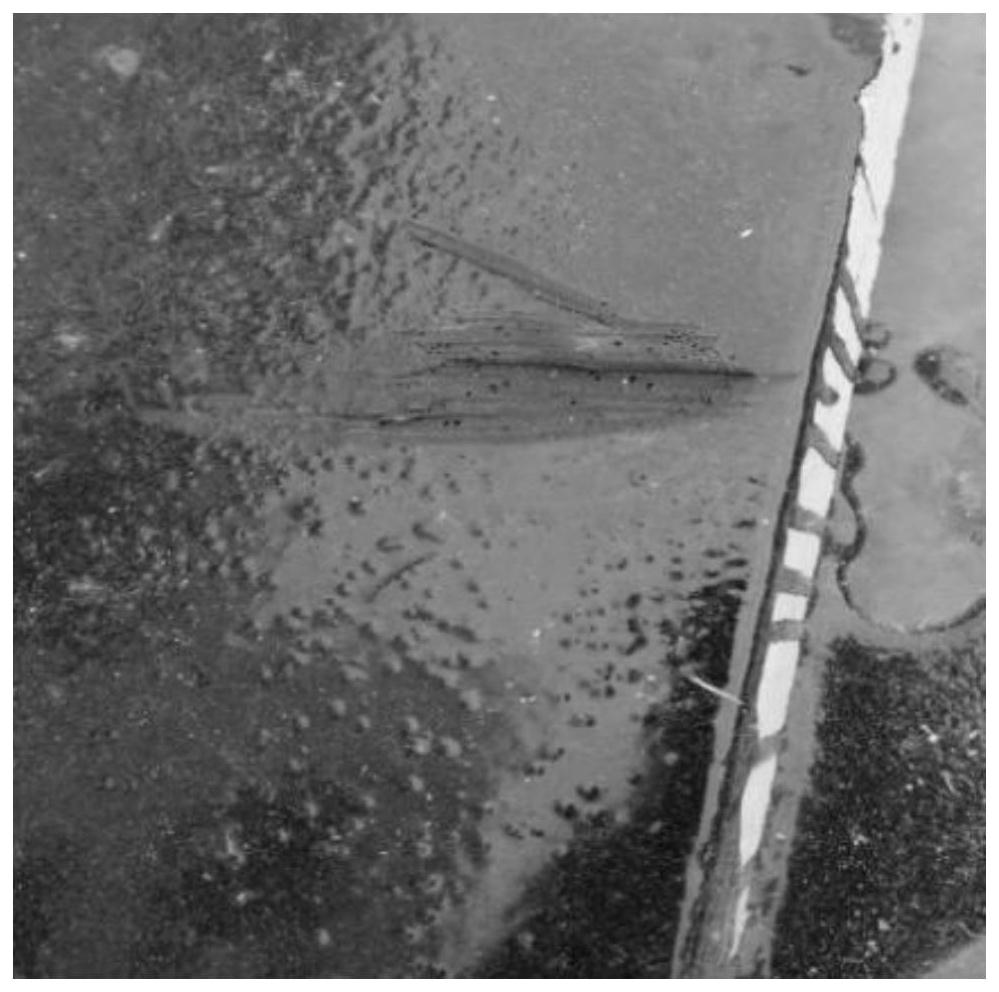

Image

Examples

preparation example Construction

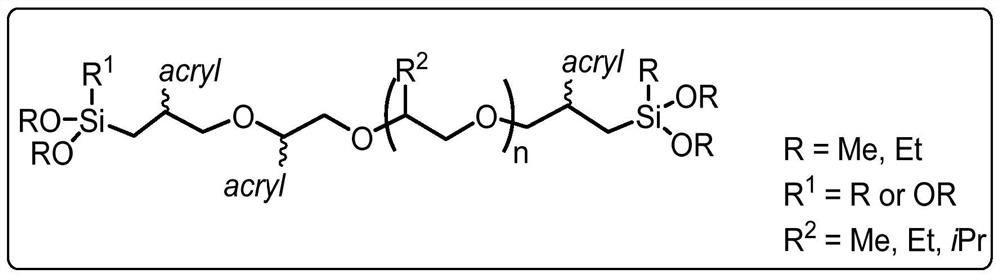

[0064] In the embodiment of the present invention, the preparation method of the solvent-free fast curing reactive waterproof coating comprises:

[0065] (1) Add alkoxy silicon-based modified polyether polymer resin, heavy powder, optional light powder, plasticizer and dispersion stabilizer to the reactor, first adjust the speed of the high-speed disperser to 1000rpm, After 5 minutes, adjust the speed of the high-speed disperser to 1750rpm, and disperse at a high speed for 40 minutes at this speed;

[0066] (2) Add dehydrating agent, coupling agent, and optional thixotropic agent, adjust the speed of the high-speed disperser to 1000rpm, keep stirring under vacuum conditions for 50min, and check the water content until the water content is ≤1200ppm;

[0067] (3) Add the catalyst under normal pressure, then stir at room temperature under vacuum for 30 minutes, turn off the agitator and the vacuum pump to obtain a solvent-free fast curing reaction type waterproof coating.

[006...

Embodiment 1

[0072] Solvent-free fast-curing reactive waterproof coating ratio: 80 parts of methyl dimethoxysilyl modified polyether polymer resin, 260 parts of heavy calcium powder, 60 parts of light calcium powder, 80 parts of plasticizer DIDP, polyamide wax 2 parts, 30 parts of terpene resin, 3 parts of vinyltrimethoxysilane, 3 parts of aminosilane coupling agent, 3 parts of dibutyltin dilaurate.

[0073] After the coating was prepared, its key physical properties were tested, and the results are shown in Table 1.

Embodiment 2

[0075] Solvent-free fast-curing reactive waterproof coating ratio: 100 parts of methyl dimethoxysilyl modified polyether polymer resin, 280 parts of talcum powder, 85 parts of fumed silica, 90 parts of DINP, 3 parts of polyamide wax, 40 parts of terpene resin, 4 parts of vinyltrimethoxysilane, 4 parts of aminosilane coupling agent, and 4 parts of catalyst dibutyltin dimercaptoacetate.

[0076] After the coating was prepared, its key physical properties were tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com