Lithium-rich ceramic coated diaphragm and preparation method thereof

A ceramic coating and lithium-rich technology, which is applied in the direction of electrical components, electrochemical generators, circuits, etc., can solve the problems of lowering the performance of the binder and affecting the performance of the lithium battery, so as to improve the adhesion, improve the service life and the battery Capacity, the effect of not shrinking easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

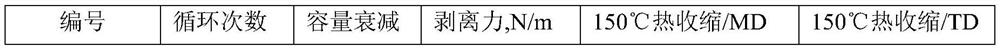

Examples

Embodiment 1

[0031] A lithium-rich ceramic coating diaphragm includes a base film, and a coating layer formed by coating lithium-rich ceramic slurry on the surface of the base film.

[0032] The raw material components of the lithium-rich ceramic slurry are, in parts by weight, 10 parts of lithium-rich ceramic powder, 3 parts of binder, and 0.5 part of crosslinking agent. in,.

[0033] A method for preparing a lithium-rich ceramic coated diaphragm: comprising the following steps;

[0034] (1) Prepare lithium-rich ceramic powder; add ceramic powder and lithium salt to 1 times the weight of water, stir and grind for 1 hour; dry at 150°C and granulate; calcinate for 2 hours at 500°C; cool , adding 1 times the weight of water, stirring, and grinding for 7 hours to obtain lithium-rich ceramic powder;

[0035] (2) preparing a lithium-rich ceramic slurry; dissolving the lithium-rich ceramic powder prepared in step (1) in water, stirring, adding a binder; stirring; adding a crosslinking agent, s...

Embodiment 2

[0038] A lithium-rich ceramic coating diaphragm includes a base film, and a coating layer formed by coating lithium-rich ceramic slurry on the surface of the base film.

[0039] The raw material components of the lithium-rich ceramic slurry are, in parts by weight, 45 parts of lithium-rich ceramic powder, 6 parts of binder, and 2 parts of crosslinking agent.

[0040] Wherein, the lithium-rich ceramic powder is synthesized from ceramic powder and lithium salt; the lithium content in the lithium-rich ceramic powder is 0.001-5%.

[0041] A method for preparing a lithium-rich ceramic coated diaphragm: comprising the following steps;

[0042] (1) Prepare lithium-rich ceramic powder; add ceramic powder and lithium salt to 1 times the weight of water, stir, and grind for 1.5 hours; dry at 153°C and granulate; calcine at 750°C for 2.5 hours ; cooling, adding 1 times the weight of water, stirring, and grinding for 8 hours to obtain lithium-rich ceramic powder;

[0043] (2) preparing ...

Embodiment 3

[0046] A lithium-rich ceramic coating diaphragm includes a base film, and a coating layer formed by coating lithium-rich ceramic slurry on the surface of the base film.

[0047] The raw material components of the lithium-rich ceramic slurry are, in parts by weight, 60 parts of lithium-rich ceramic powder, 10 parts of binder, and 10 parts of crosslinking agent.

[0048] Wherein, the lithium-rich ceramic powder is synthesized from ceramic powder and lithium salt; the lithium content in the lithium-rich ceramic powder is 5%.

[0049] A method for preparing a lithium-rich ceramic coated diaphragm: comprising the following steps;

[0050] (1) Prepare lithium-rich ceramic powder; add ceramic powder and lithium salt to 1 times the weight of water, stir and grind for 2 hours; dry at 160°C and granulate; calcinate for 3 hours at 1500°C; cool , adding 1 times the weight of water, stirring, and grinding for 9 hours to obtain lithium-rich ceramic powder;

[0051](2) preparing a lithium-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com