A kind of preparation method of sodium vanadyl fluorophosphate cathode material for sodium ion battery

A technology for sodium vanadyl fluorophosphate and sodium ion batteries, which is applied in battery electrodes, positive electrodes, secondary batteries, etc. It can solve the problems of large material particles, irregular material appearance, and small product volume, and achieve particle size distribution. Uniformity, high product consistency, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

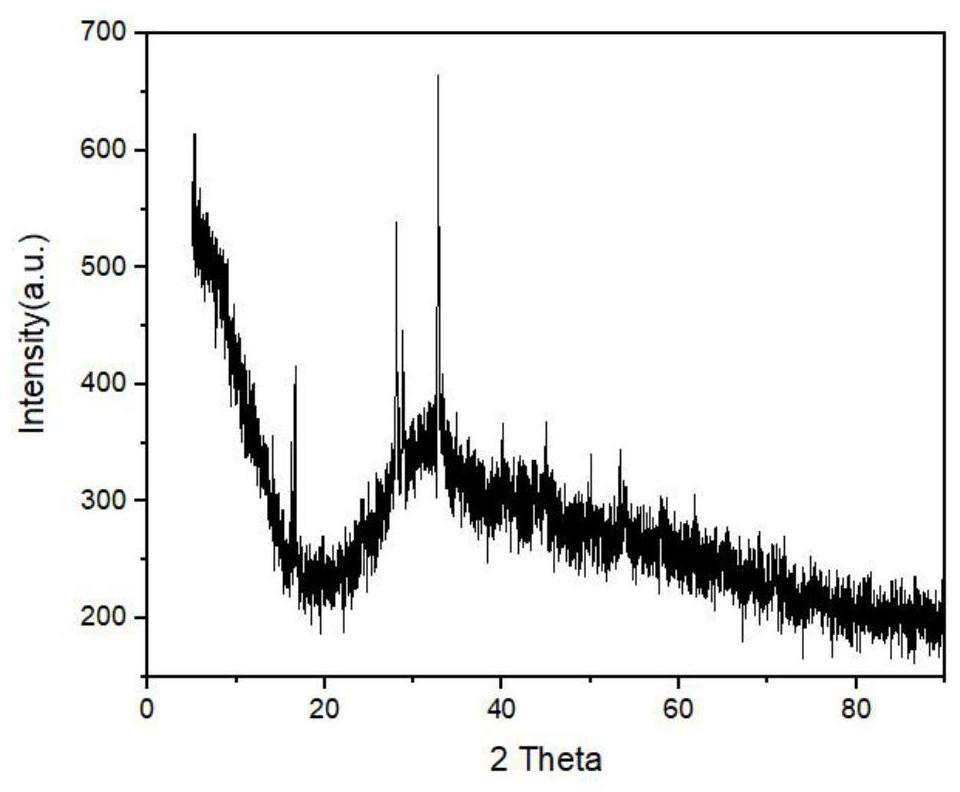

[0062] Add 2g of vanadium pentoxide to 48ml of deionized water, add 12ml of phosphoric acid (V / P molar ratio is 1:7~8), heat and stir at 80°C for 30 minutes to obtain a mixed solution, and put the solution at 500°C under argon Spray pyrolysis was carried out under air atmosphere (injection rate was 90ml / h, air intake rate was 4.5L / min), and vanadyl phosphate powder was collected (XRD showed that it was δ-VOPO 4 ), sodium fluoride, sodium acetate and vanadyl phosphate are compounded according to Na, F, vanadyl phosphate according to the chemical formula, and citric acid (citric acid / vanadyl phosphate molar ratio is 3:2) and 10ml of dispersant (alcohol or acetone), at a rotational speed of 650rpm, ball mill for 12 hours to obtain a precursor, the precursor was dried at 80°C for 2 hours, then pulverized, heated to 650°C for 8 hours under an argon atmosphere, and cooled to obtain sodium vanadyl fluorophosphate;

Embodiment 2

[0064] Add 2g of vanadium pentoxide to 48ml of deionized water, add 12ml of phosphoric acid (V / P molar ratio is 1:7~8), heat and stir at 80°C for 30 minutes to obtain a mixed solution, and put the solution at 100°C under argon Spray drying was carried out under air atmosphere (the air intake rate was 15L / min), and the vanadyl phosphate powder was collected after sintering at a temperature of 750°C (XRD showed that it was δ-VOPO 4 ), sodium fluoride, sodium acetate and vanadyl phosphate are compounded according to Na, F, vanadyl phosphate according to the chemical formula, and citric acid (citric acid / vanadyl phosphate molar ratio is 3:2) and 10ml of dispersant (alcohol or acetone), at a rotational speed of 650rpm, ball mill for 12 hours to obtain a precursor, the precursor was dried at 80°C for 2 hours, then pulverized, heated to 650°C for 8 hours under an argon atmosphere, and cooled to obtain sodium vanadyl fluorophosphate;

Embodiment 3

[0066] Add 2g of vanadium pentoxide into 48ml of deionized water, add 12ml of phosphoric acid (V / P molar ratio is 1:7~8), heat and stir at 80°C for 30 minutes to obtain a mixed solution, and co-mix the solution at 50°C Precipitate (the dropping rate is 15ml / h), then sinter at a temperature of 750°C, and collect vanadyl phosphate powder (XRD shows that it is δ-VOPO 4 ), sodium fluoride, sodium acetate and vanadyl phosphate are compounded according to Na, F, vanadyl phosphate according to the chemical formula, and citric acid (citric acid / vanadyl phosphate molar ratio is 3:2) and 10ml of dispersant (alcohol or acetone), at a rotational speed of 650rpm, ball mill for 12 hours to obtain a precursor, the precursor was dried at 80°C for 2 hours, then pulverized, heated to 650°C for 8 hours under an argon atmosphere, and cooled to obtain sodium vanadyl fluorophosphate;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com