Hydrophobic rare earth doped copper-silver alloy-carbon nano composite coating material for electrical contact and preparation method thereof

A carbon nanocomposite, copper-silver alloy technology, applied in metal material coating process, coating, pressure inorganic powder plating, etc., can solve the problems of small carbon powder specific gravity, long time-consuming, poor dispersion, etc., to achieve good durability Effects of contact impact fatigue ability, improvement of electrical conductivity and density, and improvement of strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

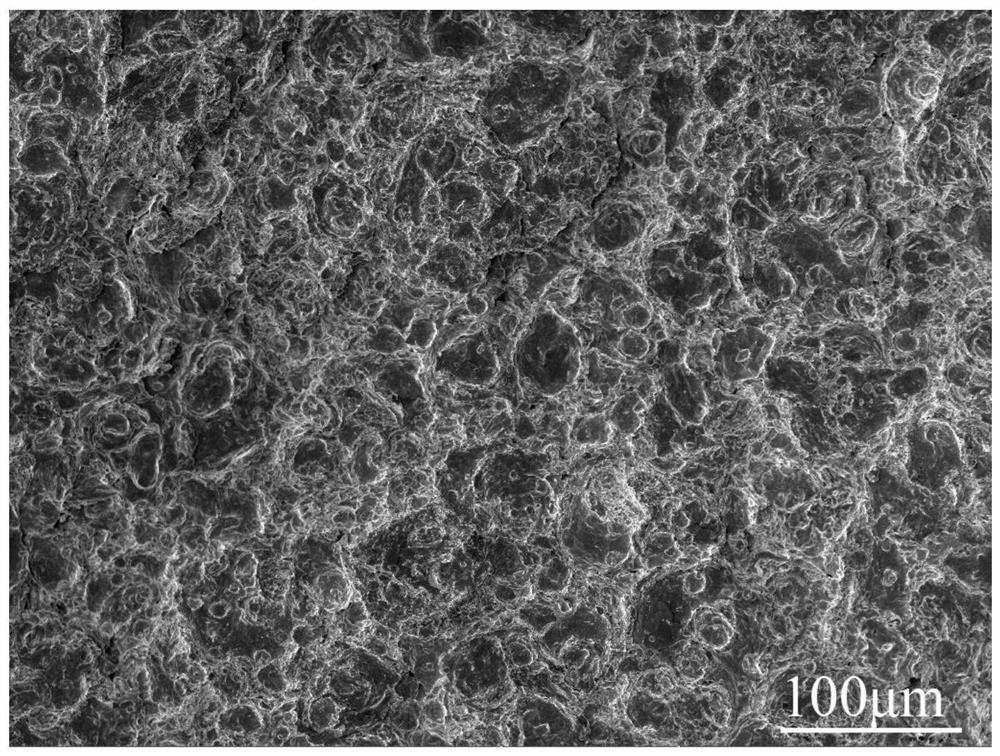

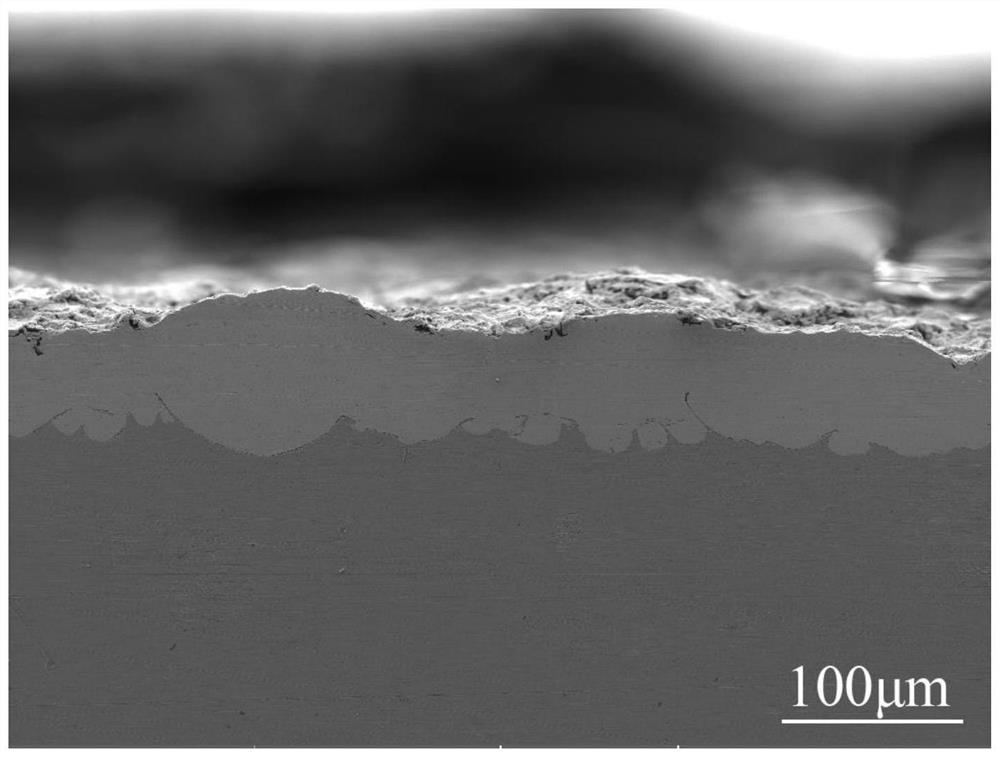

[0035] (1) Prepare copper substrates for electrical contacts with different roughnesses to be deposited. The roughness Ra of the copper substrates is 0.5 microns. Then the substrates are ultrasonically cleaned in acetone and alcohol, and dried in a nitrogen atmosphere for later use.

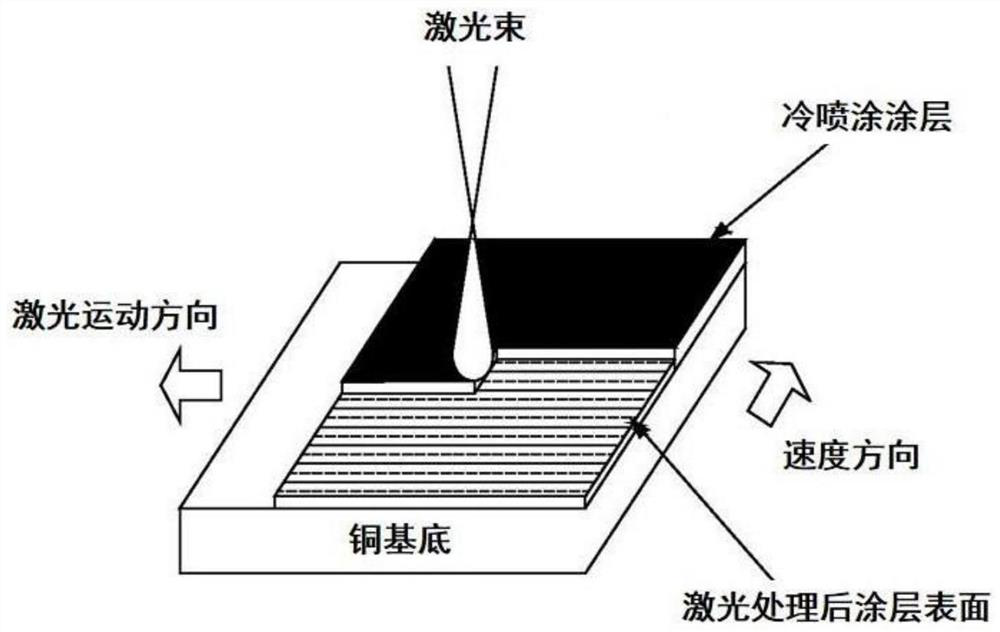

[0036](2) Rare earth-doped copper-silver alloy-carbon nanocomposite coating, wherein the copper-silver alloy powder is a high-purity powder with a purity of 99.9%, wherein the weight ratio of silver is 0.9, and the total copper-silver alloy content is 100wt.%; carbon powder It is graphite + graphene two-phase mixed powder. The silver powder particle size is 10 microns, the graphite powder particle size distribution is 10 microns, and the number of graphene layers is 1 layer. The silver powder and carbon powder are uniformly mixed by mechanical stirring, and the stirring time is controlled at 5 minutes; copper-silver alloy powder and The specific ratio distribution of the two carbon powders: the c...

Embodiment 2

[0041] (1) Prepare copper substrates for electrical contacts with different roughnesses to be deposited, the roughness Ra of the copper substrates is 50 microns, and then ultrasonically clean the substrates in acetone and alcohol, and dry them in a nitrogen atmosphere for later use.

[0042] (2) Rare earth-doped copper-silver alloy-carbon nanocomposite coating, wherein the copper-silver alloy powder is a high-purity powder with a purity of 99.9%, wherein the weight ratio of silver is 0.8, and the total copper-silver alloy content is 75wt.%; carbon powder It is graphite + graphene two-phase mixed powder. The particle size of copper-silver alloy powder is 70 microns, the particle size distribution of graphite powder is 50 microns, and the number of graphene layers is 20 layers. The silver powder and carbon powder are uniformly mixed by mechanical stirring, and the stirring time is controlled at 20 minutes; silver powder and carbon The specific ratio distribution of the two powde...

Embodiment 3

[0047] (1) Prepare copper substrates for electrical contacts with different roughnesses to be deposited. The roughness Ra of the copper substrates is 0.5-50 microns. Then the substrates are ultrasonically cleaned in acetone and alcohol, and dried in a nitrogen atmosphere for later use.

[0048] (2) Rare earth-doped copper-silver alloy-carbon nanocomposite coating, wherein the copper-silver alloy powder is a high-purity powder with a purity of 99.9%, wherein the weight ratio of silver is 0.7, and the total copper-silver alloy content is 80wt.%; carbon powder It is graphite + graphene two-phase mixed powder. The particle size of copper and silver powder is 50 microns, the particle size distribution of graphite powder is 40 microns, and the number of graphene layers is 10 layers. The silver powder and carbon powder are uniformly mixed by mechanical stirring, and the stirring time is controlled at 10 minutes; silver powder and carbon powder The specific proportion distribution of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com