Asymmetric star-shaped hydrogenated block copolymer and preparation method and application thereof

A hydrogenated styrene-butadiene block and asymmetric technology, which is applied in the field of polymers, can solve the problems of large compression set, large decline in mechanical properties, and failure to meet sealing strips, etc., and achieve long service life, excellent UV resistance, and improved The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

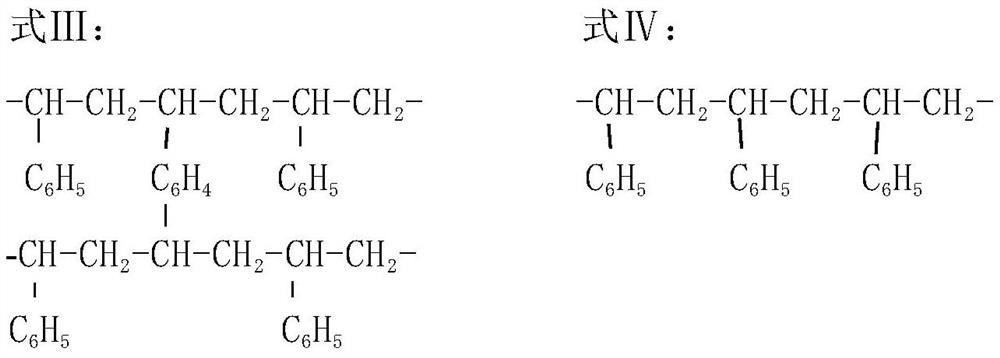

Method used

Image

Examples

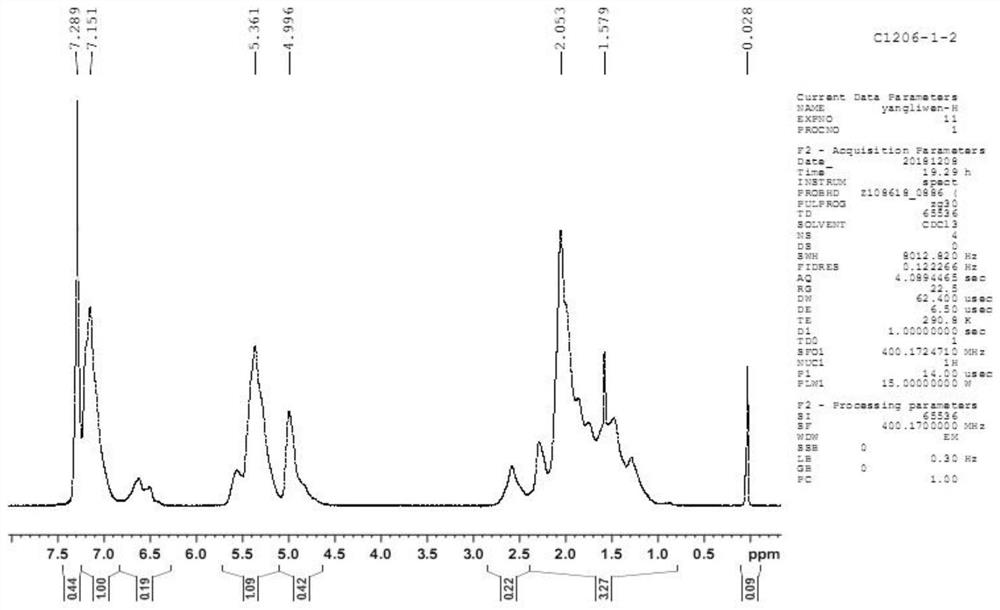

Embodiment 1

[0082] Add 2.5 liters of cyclohexane and raffinate oil mixture (the mixing ratio of cyclohexane and raffinate oil is 9:1) into the 5 liter polymerization kettle purged with nitrogen, which contains 500 mg / kg of solvent of tetrahydrofuran. The temperature of the mixture was raised to 50° C., 67 g of styrene, 0.20 g of pentamethyldiethylenetriamine, and then 3.57 mmol of n-butyllithium were added to initiate the reaction. After stirring and reacting for 20-30 minutes, add 150g of butadiene into the active polymer, control the reaction temperature at 65-75°C, stir and react for 20-40min, then add a mixture of 33g of styrene and 1.25g of divinylbenzene Put the monomer into the active polymer, stir and react for 20 to 30 minutes, then add 0.9 mmol of coupling agent silicon tetrachloride, and stir and react for 10 to 30 minutes. After the polymerization, press the polymer into a 5-liter hydrogenation tank, control the temperature at 50-100 °C, add 68 mmg of methyl benzoate to the hy...

Embodiment 2

[0084] Implementation steps are the same as in Example 1, changing the addition of each material and controlling the reaction temperature. Wherein the solvent is in the same amount as tetrahydrofuran. In the first stage, 60 g of styrene and 0.25 g of tetramethylethylenediamine were added, and then 3.57 mmol of n-butyllithium was added to initiate the reaction. Add 175g of butadiene in the second stage, during which the reaction temperature is controlled at 50-65°C, add a mixture of 15g of styrene and 1.5g of divinylbenzene into the active polymer in the third stage, and then add 0.9mmol of the coupling agent silicon tetrachloride Perform coupling. After the polymerization, carry out the hydrogenation reaction for 60-120 minutes, and add 5ml of water to terminate the reaction. 0.6% antioxidant based on the weight of the polymer was added to the reaction mixture. The solid is separated, and the drying oven is devolatilized to obtain an asymmetric star-shaped hydrogenated bloc...

Embodiment 3

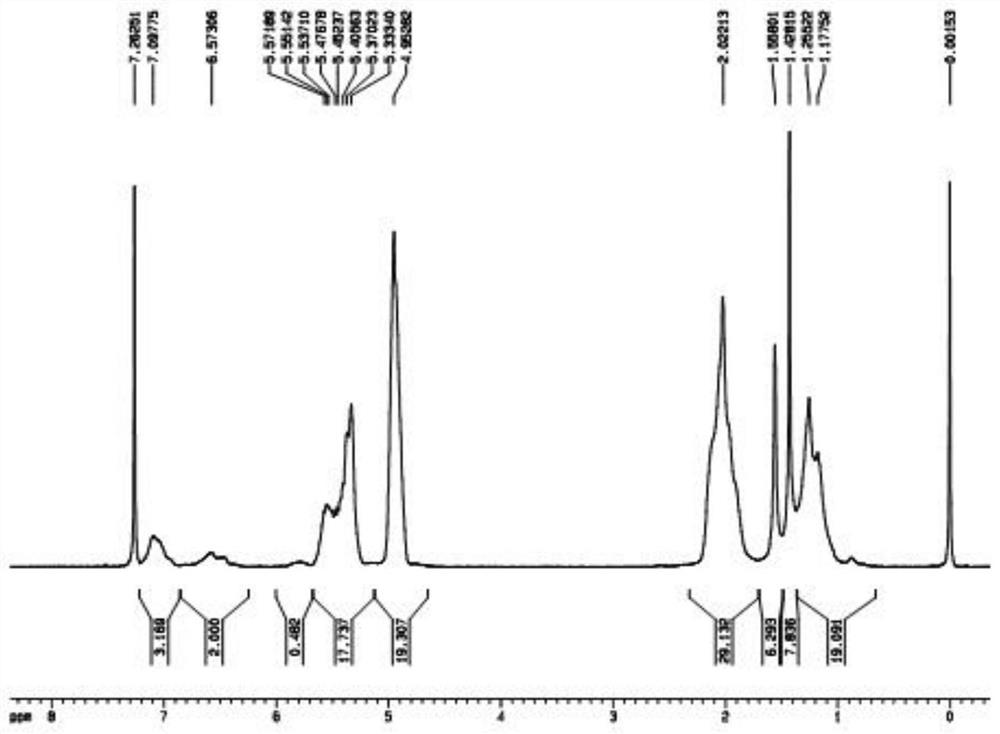

[0086] Step is all identical with embodiment 1 except conditioner and material addition. The regulator is 0.48 g of tetrahydrofurfuryl alcohol ethyl ether, the coupling agent is divinylbenzene, and the amount of coupling agent added is 1.4 g. Meanwhile, the reaction temperature is controlled at 40-55°C, the reaction is stirred for 40-60 minutes, and then an asymmetric star-shaped hydrogenated block copolymer (S 1 EBS 2 )nDVB. The molecular weight of the copolymer is 347388 (Mn), the coupling degree is 6.15, the coupling efficiency is 83.57%, and the 1,2-structure content of the PB segment is 70.5%. NMR spectrum see figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com