Non-ferrous smelting waste recovery system and use method thereof

A waste recycling and non-ferrous technology, applied in the direction of improving process efficiency, can solve the problems of high zinc content, low metal leaching rate, low recovery space and economic value, etc. and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

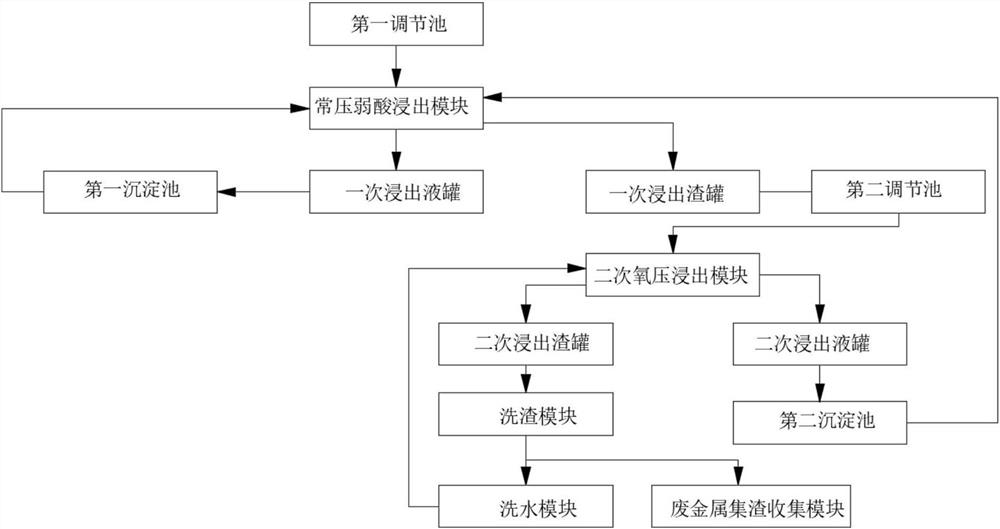

[0025] see Picture 1-1 , the present invention provides a technical solution: a non-ferrous smelting waste recovery system, including a first regulating tank, an atmospheric weak acid leaching module, a first sedimentation tank, a primary leaching liquid tank, a primary leaching slag tank, a second regulating tank, a secondary Oxygen pressure leaching module, secondary leaching slag tank, secondary leaching liquid tank, slag washing module, second sedimentation tank, water washing module and scrap metal slag collection module, the first regulating tank is connected to the normal pressure weak acid leaching module, normal pressure weak acid The leaching module is connected to the primary liquid discharge tank and the primary slag discharge tank, the primary slag discharge tank is connected to the second regulating tank, the second regulating tank is connected to the secondary oxygen pressure leaching module, and the secondary oxygen pressure leaching module is connected to the ...

Embodiment 2

[0040] see Picture 1-1 , the present invention provides a technical solution: a non-ferrous smelting waste recovery system, including a first regulating tank, an atmospheric weak acid leaching module, a first sedimentation tank, a primary leaching liquid tank, a primary leaching slag tank, a second regulating tank, a secondary Oxygen pressure leaching module, secondary leaching slag tank, secondary leaching liquid tank, slag washing module, second sedimentation tank, water washing module and scrap metal slag collection module, the first regulating tank is connected to the normal pressure weak acid leaching module, normal pressure weak acid The leaching module is connected to the primary liquid discharge tank and the primary slag discharge tank, the primary slag discharge tank is connected to the second regulating tank, the second regulating tank is connected to the secondary oxygen pressure leaching module, and the secondary oxygen pressure leaching module is connected to the ...

Embodiment 3

[0055] see Picture 1-1 , the present invention provides a technical solution: a non-ferrous smelting waste recovery system, including a first regulating tank, an atmospheric weak acid leaching module, a first sedimentation tank, a primary leaching liquid tank, a primary leaching slag tank, a second regulating tank, a secondary Oxygen pressure leaching module, secondary leaching slag tank, secondary leaching liquid tank, slag washing module, second sedimentation tank, water washing module and scrap metal slag collection module, the first regulating tank is connected to the normal pressure weak acid leaching module, normal pressure weak acid The leaching module is connected to the primary liquid discharge tank and the primary slag discharge tank, the primary slag discharge tank is connected to the second regulating tank, the second regulating tank is connected to the secondary oxygen pressure leaching module, and the secondary oxygen pressure leaching module is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com