High-temperature powdery iron ore reduced calcine segmented cooling method

A staged cooling and powdery technology, which is applied in the field of staged cooling of high-temperature powdered iron ore reduction calcined sand, can solve the problems of unsatisfactory market demand, unreasonable economy, and technical infeasibility, etc., so as to reduce roasting heat consumption and reduce Effect of heat loss and improvement of magnetic conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

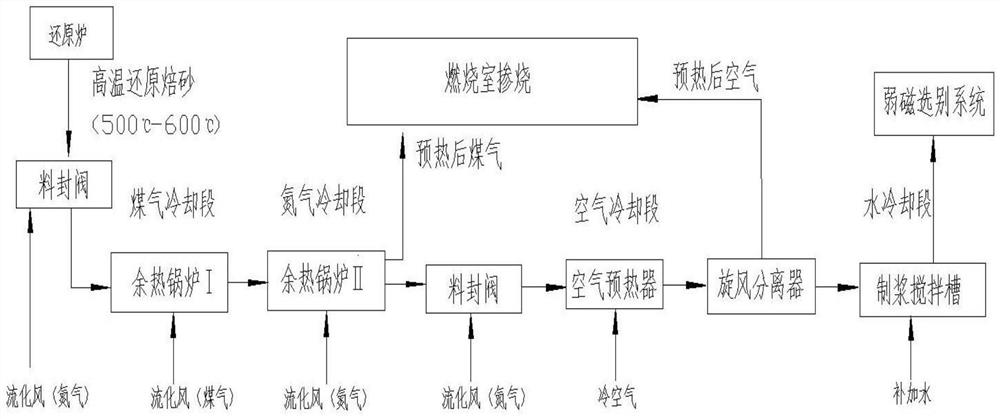

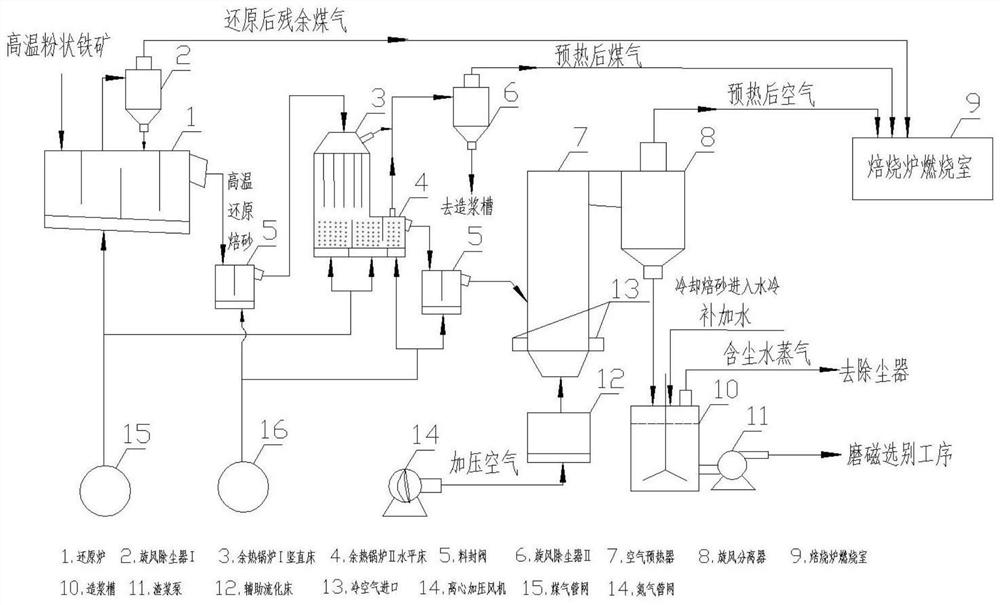

[0034] Such as figure 1 , figure 2 As shown in the flow chart: Cooling system process structure description: The waste heat boiler is an L-shaped structure, which can be divided into two parts, one part is a vertical moving bed, which is divided into evaporator Ⅰ, high-temperature superheater, low-temperature superheater and Evaporator II; part of it is a horizontal fluidized bed, inside which are vertically arranged multiple groups of partition walls composed of boiler bundle tubes that stagger up and down, and horizontally divided into evaporator III, medium pressure economizer I, II and low pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com