Low-nitrogen efficient module combined unit structure

A technology of unit structure and module combination, which is applied in the direction of gas fuel burners, combustion methods, and greenhouse gas reduction, can solve the problems that the latent heat of vaporization cannot be recovered, and the efficiency is low, so as to make full use of latent heat, improve heat exchange efficiency, and be practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

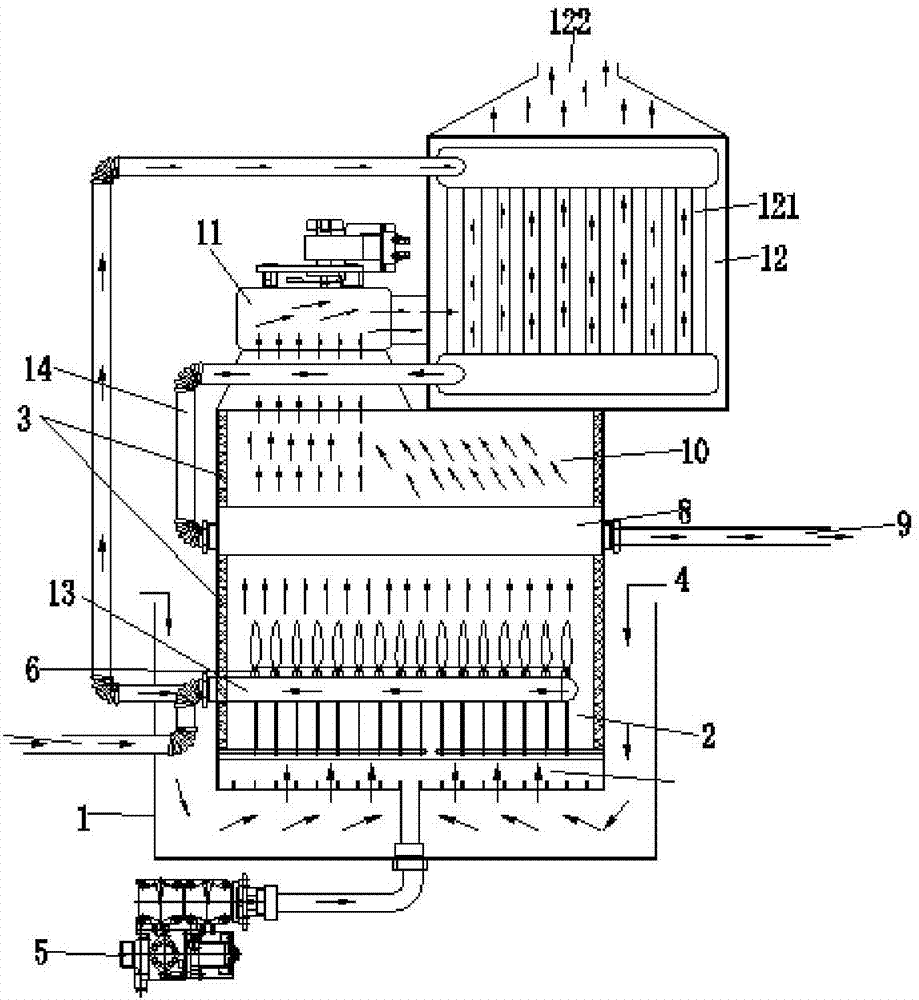

[0014] Such as figure 1 As shown, a low-nitrogen high-efficiency module combination unit structure includes a cover body 1, a combustion chamber 2 is provided inside the cover body 1, a heat insulation layer 3 is provided on both sides of the combustion chamber 2, and a heat insulating layer 3 is provided between the combustion chamber 2 and the cover body 1 Air enters the channel 4, and the lower part of the combustion chamber 2 is provided with a gas inlet 5.

[0015] The combustion chamber 2 is provided with a nozzle 6, the cold water pipe 7 passes through the cover body 1 and extends to the heating pipe 8, the heating pipe 8 is arranged on the upper part of the nozzle 6, the other end of the heating pipe 8 is provided with a hot water pipe 9, and the upper part of the combustion chamber 2 is provided with a There is a steam chamber 10, the upper part of the steam chamber 10 is provided with a strong exhaust fan 11, one end of the strong exhaust fan 11 communicates with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com