Flexible metal composite fiber porous material as well as preparation method and application thereof

A composite fiber and flexible metal technology, which is applied in the field of metal porous materials, can solve the problems of fiber preparation and sintering into felt, and achieve the effects of easy operation, avoiding falling off, and improving interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention provides a method for preparing the flexible metal composite fiber porous material described in the above technical solution. When prepared by magnetron sputtering, it includes the following steps:

[0035] Using a high-purity tungsten target as a sputtering source and argon as a working gas, depositing a tungsten layer by magnetron sputtering on the flexible base layer of the metal porous material to obtain the flexible metal composite fiber porous material;

[0036] When it is prepared by chemical vapor deposition, it includes the following steps: using the precursor gas of tungsten and reducing gas as the reaction gas, passing through the carrier gas, performing chemical vapor deposition on the flexible base layer of the metal porous material, and forming tungsten on the surface of the metal fiber. deposition layer to obtain the flexible metal composite fiber porous material; the precursor gas of the tungsten is tungsten halide gas.

[0037] In ...

Embodiment 1

[0060] Three strands of Cu fiber filaments with a diameter of 12 μm were twisted to make Cu yarns, which were used as a flexible substrate for magnetron sputtering. The process is as follows:

[0061] First, the Cu yarn is subjected to alkali washing (5wt% sodium hydroxide solution) to remove oil, then pickling (5wt% hydrochloric acid) to remove the oxide layer, and finally deionized water to clean and dry;

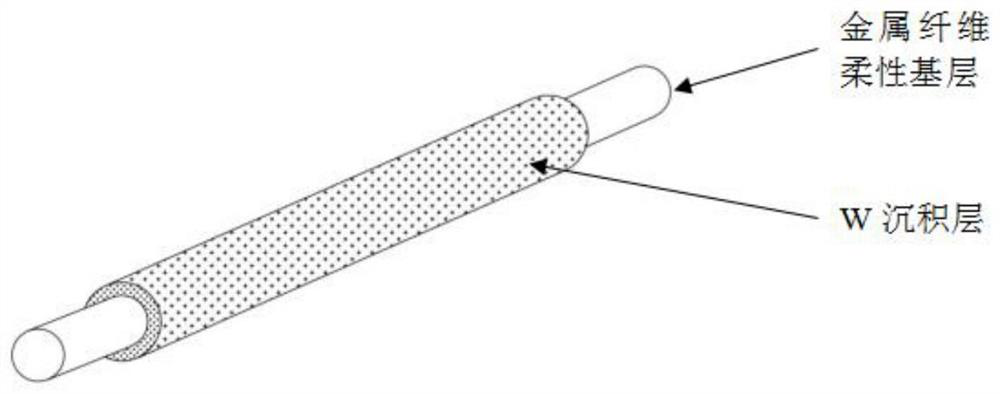

[0062] The Cu yarn after pretreatment is wound on the I-shaped wheel and placed in the magnetron sputtering device; the target material is pure tungsten target, the sputtering power is 200W, the pressure is 5Pa, the protective atmosphere is argon, and the Cu yarn on the I-shaped wheel The fiber bundle is pulled through the tungsten target (W), and the tungsten produced by magnetron sputtering is deposited on the Cu fiber and interfacially bonded to obtain a flexible Cu / W composite yarn (such as figure 1 Shown) is wound on another I-shaped wheel, and the axis directions of...

Embodiment 2

[0066] The stainless steel fiber needle-punched felt with a porosity of 80% and a wire diameter of 8 μm is used as a flexible base layer, which is firstly washed with alkali (5wt% sodium hydroxide solution) to remove oil, and then acid washed (5wt% hydrochloric acid) to remove the oxide layer , and finally cleaned with deionized water, dried and placed in a closed reaction chamber of a chemical vapor deposition (CVD) device for deposition. The process is as follows:

[0067] Will WF 6 After being heated above the boiling point and vaporized, it is passed into the reaction chamber, and evenly dispersed on the preheated stainless steel fiber needle felt. The stainless steel fiber felt is heated to a deposition temperature of 500°C, and then H 2 and carrier gas Ar, WF 6 and H 2 The molar ratio is 1:4, the carrier gas Ar rate is 1L / min, chemical vapor deposition is carried out, the reaction pressure is 300Pa, H 2 The rate is 1.5L / min, WF 6 The rate is 2 g / min, the deposition r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com