Method for continuously producing high-molecular-weight polyether by adopting micro-channel reactor

A micro-channel reactor, micro-reactor technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, chemical/physical/physical-chemical processes, etc., can solve the complex process, low reaction speed, synthesis cycle long-term issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Embodiment 1: (synthesis of low molecular weight polyether Mn=2400)

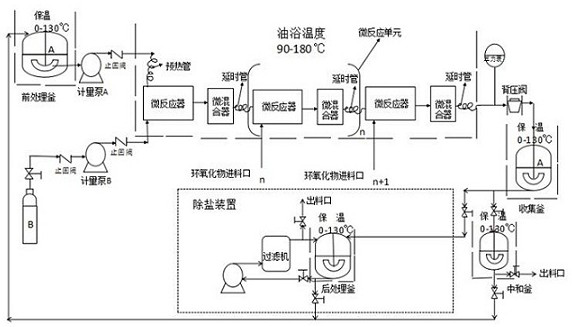

[0090] (1) The device used: a continuous microreactor system, refer to figure 1System device diagram connection, you can choose 2 micro-reaction units. Among them, the microreactor can use one or more microreactors from Guizhou Microchem Technology Co., Ltd., Dalian Microchem Chemical Co., Ltd., and Chemtrix BV in the Netherlands. The micromixer can use Guizhou Microchem Technology Co., Ltd. One or more of the Micromixers of Ltd. Adjust the length of the delay tube to determine the reaction residence time, the heat exchange medium is high-temperature heat transfer oil, and the neutralization tank is a 5L conventional alkoxylation small-scale reactor.

[0091] (2) First prepare low-molecular-weight polyether F in the microreactor system: add 100g of propylene glycol as an initiator to the pre-treatment tank in advance, add catalyst 0.1% sodium metal, and degas between -0.05MPa±0.05MPa, After the nit...

Embodiment 2

[0095] Embodiment 2: (synthesis of high molecular weight polyether polyol Mn=5000)

[0096] (1) The device used: a continuous microreactor system, refer to figure 1 The system device diagram is connected, and there are 3 micro-reaction units. Among them, one or more microreactors from Guizhou Microchem Technology Co., Ltd., Dalian Microchem Chemical Co., Ltd., and ChemtrixBV from the Netherlands can be used for the microreactor. Guizhou Microchem Technology Co., Ltd., Dalian Microchem Chemical Co., Ltd. One or more of the company's Micromixers. Adjust the length of the delay tube to determine the reaction residence time. The heat exchange medium is high-temperature heat transfer oil. Both the collection tank and the neutralization tank are 5L conventional alkoxylation small-scale reactors.

[0097] (2) First prepare low-molecular-weight poly-F in the microreactor system: add 100g of propylene glycol as an initiator to the pre-treatment tank in advance, add a catalyst of 0.2%...

Embodiment 3

[0101] Embodiment 3: (synthesis of high molecular weight polyether polyol Mn=8000)

[0102] (1) The device used: a continuous microreactor system, refer to figure 1 The connection of the system device diagram, there are 4 micro-reaction units. Among them, one or more microreactors from Guizhou Microchem Technology Co., Ltd., Dalian Microchem Chemical Co., Ltd., and ChemtrixBV from the Netherlands can be used for the microreactor. Guizhou Microchem Technology Co., Ltd., Dalian Microchem Chemical Co., Ltd. One or more of the company's Micromixers. Adjust the length of the delay tube to determine the reaction residence time. The heat exchange medium is high-temperature heat transfer oil. The collection tank, neutralization tank and post-treatment tank are all 5L conventional alkoxylation small-scale reactors.

[0103] (2) First prepare low-molecular-weight poly-F in the microreactor system: add 100g glycerol as an initiator to the pre-treatment tank in advance, add catalyst 0.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com