High-temperature-resistant high-airtightness composite material for repairing heat distribution pipeline, and preparation method and application of high-temperature-resistant high-airtightness composite material

A composite material and heat pipeline technology, which is applied in the field of high air tightness composite material and its preparation, high temperature resistance, can solve the problems of high temperature resistance and poor air tightness, achieve good mechanical properties, increase alkalinity, weaken the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

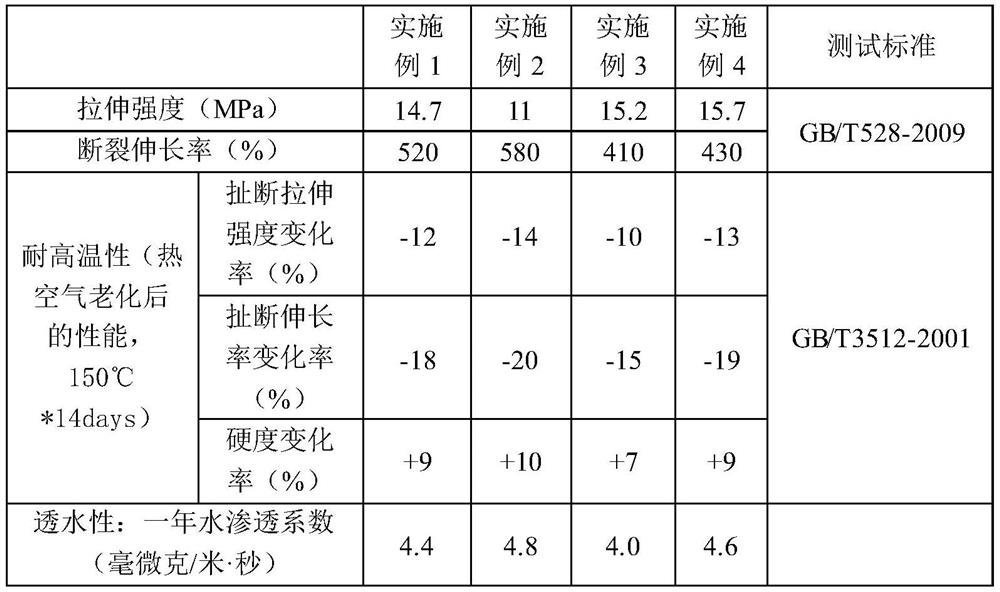

Examples

Embodiment 1

[0040] A high-temperature-resistant, high-air-tight composite material for thermal pipeline repair, including the following raw materials in parts by weight: 100 parts of binary ethylene-propylene rubber, 8 parts of PIB, 4 parts of nano-zinc oxide, 4 parts of polyethylene glycol, peroxide 3 parts of cross-linking agent, 1.5 parts of auxiliary cross-linking agent, 1.5 parts of anti-aging agent, 35 parts of carbon black N55035, 15 parts of white carbon black, 10 parts of paraffin oil, 2 parts of resorcinol, 2 parts of formaldehyde donor, sheet 40 parts of talcum powder.

[0041] Wherein, the molecular weight of the PIB is 20000g / mol.

[0042] Wherein, the polyethylene glycol is PEG-4000.

[0043] Wherein, the peroxide crosslinking agent is 2,5-dimethyl-2,5-di-tert-butylperoxy-3-hexyne.

[0044] Wherein, the auxiliary crosslinking agent is trienylmethyl triisocyanurate.

[0045] Wherein, the anti-aging agent is 4-methyl-6-tert-butylphenol.

[0046] Wherein, the paraffin oil is ...

Embodiment 2

[0052] A high-temperature-resistant, high-air-tight composite material for thermal pipeline repair, including the following raw materials in parts by weight: 100 parts of binary ethylene-propylene rubber, 5 parts of PIB, 5 parts of nano-zinc oxide, 2 parts of polyethylene glycol, peroxide 1 part of cross-linking agent, 1 part of auxiliary cross-linking agent, 0.5 part of anti-aging agent, 15 parts of carbon black N550, 15 parts of white carbon black, 5 parts of paraffin oil, 1 part of resorcinol, 1 part of formaldehyde donor, tablet 20 parts of talcum powder.

[0053] Wherein, the molecular weight of the PIB is 10000 g / mol.

[0054] Wherein, the polyethylene glycol is PEG-4000.

[0055] Wherein, the peroxide crosslinking agent is 2,5-dimethyl-2,5-di(t-butylperoxy)hexane.

[0056] Wherein, the auxiliary crosslinking agent is N,N'-m-phenylene bismaleimide.

[0057] Wherein, the anti-aging agent is 2-mercaptobenzimidazole.

[0058] Wherein, the paraffin oil is 2280.

[0059]...

Embodiment 3

[0064] A high-temperature-resistant, high-air-tight composite material for thermal pipeline repair, including the following raw materials in parts by weight: 100 parts of binary ethylene-propylene rubber, 10 parts of PIB, 3 parts of nano-zinc oxide, 5 parts of polyethylene glycol, peroxide 5 parts of cross-linking agent, 2 parts of auxiliary cross-linking agent, 3 parts of anti-aging agent, 60 parts of carbon black N550, 15 parts of white carbon black, 15 parts of paraffin oil, 3 parts of resorcinol, 3 parts of formaldehyde donor, tablet 60 parts of talcum powder.

[0065] Wherein, the molecular weight of the PIB is 20000g / mol.

[0066] Wherein, the polyethylene glycol is PEG-4000.

[0067] Wherein, the peroxide crosslinking agent is tert-butyl peroxyisopropyl carbonate.

[0068] Wherein, the auxiliary crosslinking agent is N,N'-m-phenylene bismaleimide.

[0069] Wherein, the anti-aging agent is 4-methyl-6-tert-butylphenol and 2-mercaptobenzimidazole (mass ratio 2:1).

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com