Preparation method of composite material, composite material and application of composite material

A composite material and polymer technology, applied in the field of preparation of organic porous polymer composite materials, can solve the problems of uneven spreading, reducing the resistance of the precursor solution, and the difficulty of compounding MOFs and supporting materials, etc., to improve the mass transfer rate and The effect of adsorption efficiency, high mechanical strength and fast adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

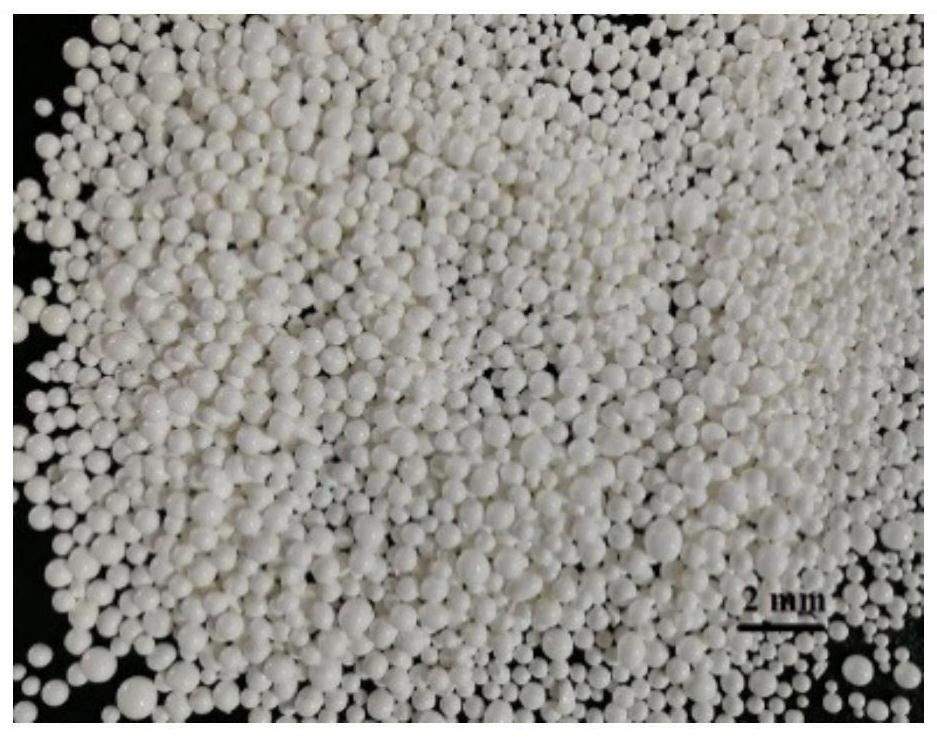

[0032] Accurately weigh 1.6g of acrylamide, 0.4g of N,N-methylenebisacrylamide, 0.1g of poloxamer F127, and 0.03g of ammonium persulfate, dissolve them in 5ml of deionized water, and ultrasonicate for 5min to obtain the water phase; Mix 11ml of toluene and 5ml of cyclohexane evenly to obtain an oil phase; stir the water phase at a speed of 3000r / min, add the oil phase to the water phase, and continue stirring for 5min to form a uniform and stable emulsion. Measure 15ml of toluene, 15ml of carbon tetrachloride, and 60ml of cyclohexane, and add 0.15g of ethyl cellulose to mix evenly as the third phase. Pour the emulsion into the third phase under the protection of nitrogen. Then, 14 drops of reducing agent N,N,N',N'-tetramethylethylenediamine were added, and cross-linking polymerization was carried out at 65°C for 30min. After solidification, the balls were taken out and washed with ethanol and placed in an oven to dry to constant weight, and then the dried polymer particles wer...

Embodiment 2

[0036] The preparation process of polyacrylamide particles is the same as in Example 1. Accurately weigh 2.1g of metal salt zirconium chloride, measure 7.5ml of acetic acid, and ultrasonically dissolve it in 15ml of N,N-dimethylformamide to prepare A solution, then weigh 1.1g of fumaric acid, measure 1.0ml of three Ethylamine was ultrasonically dissolved in 15ml N,N-dimethylformamide to prepare B solution, and then A solution and B solution were ultrasonically mixed to obtain a precursor solution, which was poured into 0.3g dry polypropylene In the flask of amide particles, the flask was reacted in an 85°C oil bath for 24h, and MOFs particles grew on the macroporous surface of the porous polymer. After washing and drying at 150°C for 24h, they were activated to obtain MOFs / polyacrylamide composites.

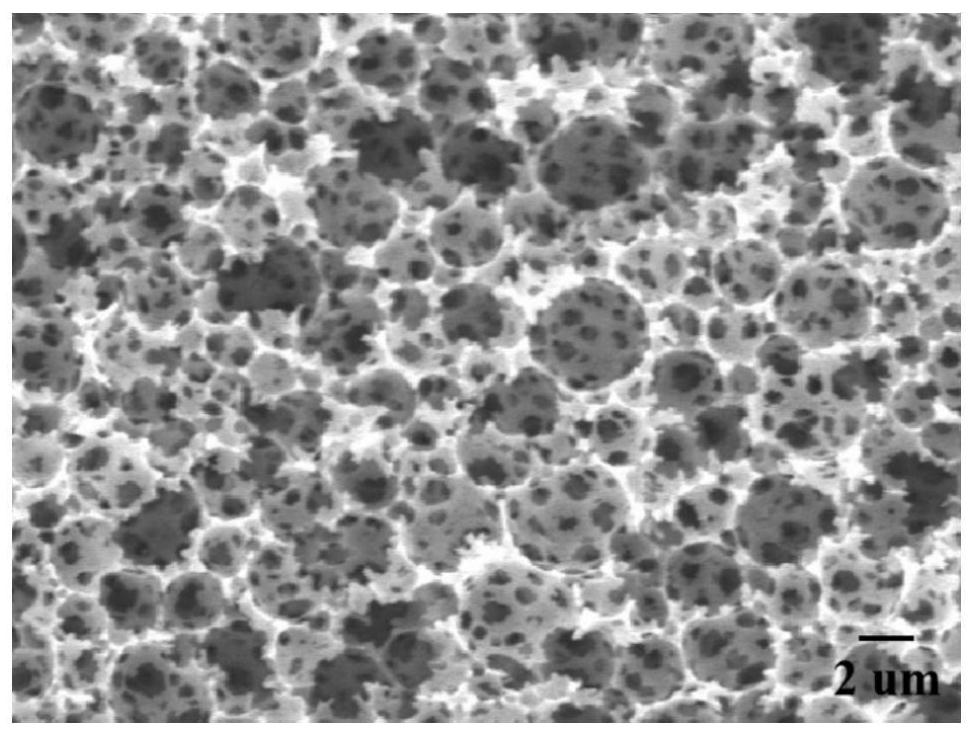

[0037] The scanning electron microscope image of the internal pore structure of the MOFs / polyacrylamide composite material prepared in this example is shown in Figure 4 , it ca...

Embodiment 3

[0039] The preparation process of polyacrylamide particles is the same as in Example 1. Accurately weigh 2.1g of metal salt zirconium chloride, measure 15ml of acetic acid, ultrasonically dissolve it in 15ml of N,N-dimethylformamide to prepare A solution, then weigh 1.1g of fumaric acid, measure 2.0ml of trimethylamine Ultrasonic dissolved in 15ml N,N-dimethylformamide to prepare B solution, then ultrasonically mixed solution A and solution B to obtain a precursor solution, and poured it into 0.3g dry polyacrylamide particles In the flask, the flask was reacted in an oil bath at 100°C for 24h, and MOFs particles grew on the macroporous surface of the porous polymer. After washing, the solvent was removed in a vacuum drying oven for 24h to activate, and the MOFs / polyacrylamide composite material was obtained. .

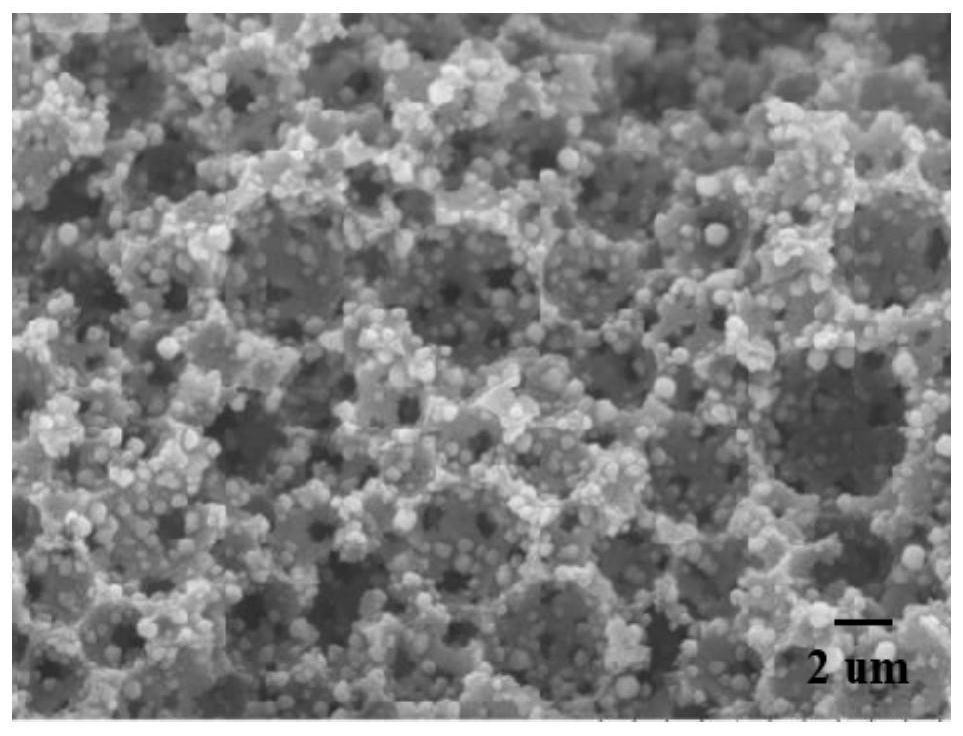

[0040] The scanning electron microscope image of the internal pore structure of the MOFs / polyacrylamide composite material prepared in this example is shown in Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com