Crystalline self-repairing polymer cement-based waterproof material and preparation method thereof

A technology of waterproof materials and polymers, applied in the field of waterproof materials, can solve problems such as compatibility or dispersion delamination, cracks, etc. that cannot be completely solved from the root cause

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

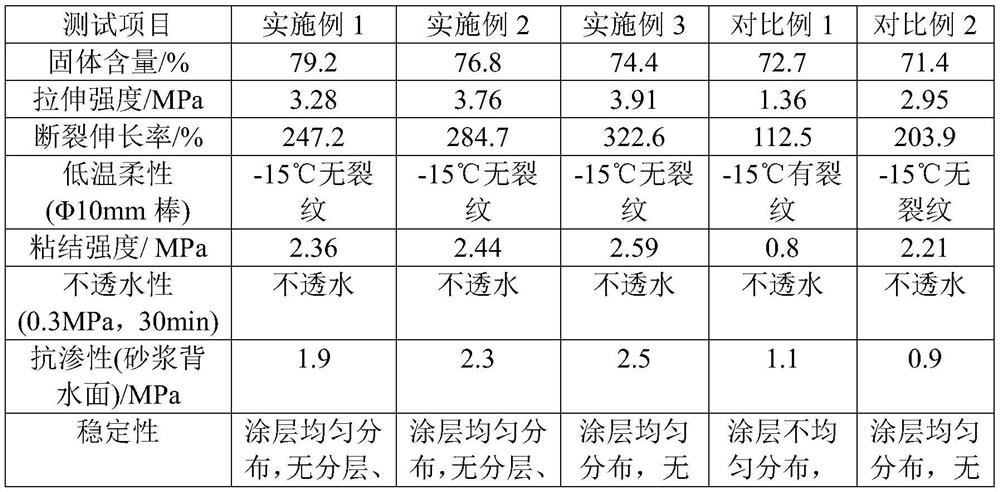

Examples

Embodiment 1

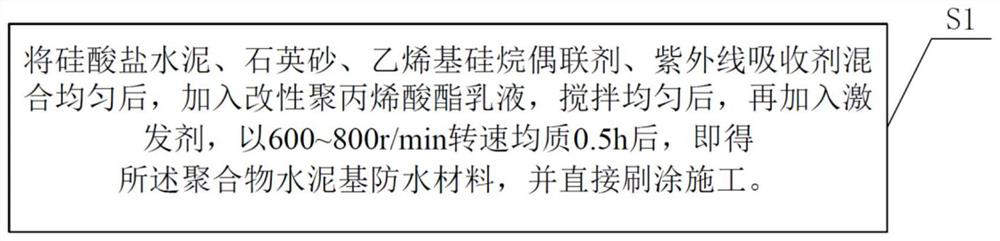

[0024] A preparation method for a crystalline self-repairing polymer cement-based waterproof material, comprising the following steps:

[0025] S1: Preparation of modified polyacrylate emulsion:

[0026] I. Weigh 20 parts of methyl acrylate, 1 part of methacrylic acid, 20 parts of ethanol, 5 parts of sodium itaconate, 3 parts of sodium styrene sulfonate, 3 parts of tetrasodium iminodisuccinate, 0.1 parts of ammonium sulfate, 20 parts of deionized water;

[0027] II. Add methyl acrylate and methacrylic acid into ethanol, stir and dissolve to obtain liquid A;

[0028] III. Add sodium itaconate, sodium styrene sulfonate, tetrasodium iminodisuccinate, and ammonium persulfate into deionized water, stir and dissolve to obtain liquid B;

[0029] IV. After mixing liquid A and liquid B evenly, transfer them to a reaction kettle, and carry out a copolymerization reaction at 70°C for 3 hours to obtain a modified polyacrylate emulsion;

[0030] S2: Weigh 10 parts of sodium silicate, 15...

Embodiment 2

[0033] A preparation method for a crystalline self-repairing polymer cement-based waterproof material, comprising the following steps:

[0034] S1: Preparation of modified polyacrylate emulsion:

[0035] I. Weigh 22 parts of methyl methacrylate, 2 parts of methacrylic acid, 23 parts of ethanol, 8 parts of sodium itaconate, 5 parts of sodium styrene sulfonate, and 6 parts of tetrasodium iminodisuccinate successively by mass parts , 0.15 parts of potassium persulfate, 24 parts of deionized water;

[0036] II. Add methyl methacrylate and methacrylic acid into ethanol, stir and dissolve to obtain liquid A;

[0037] III. Add sodium itaconate, sodium styrene sulfonate, tetrasodium iminodisuccinate, and potassium persulfate into deionized water, stir and dissolve to obtain liquid B;

[0038] IV. After mixing liquid A and liquid B evenly, transfer them to a reaction kettle, and perform a copolymerization reaction at 85°C for 3-6 hours to obtain a modified polyacrylate emulsion;

[...

Embodiment 3

[0042] A preparation method for a crystalline self-repairing polymer cement-based waterproof material, comprising the following steps:

[0043] S1: Preparation of modified polyacrylate emulsion:

[0044] I. Weigh successively 25 parts of ethyl acrylate, 3 parts of methacrylic acid, 25 parts of ethanol, 10 parts of sodium itaconate, 7 parts of sodium styrene sulfonate, 10 parts of tetrasodium iminodisuccinate, 0.2 parts of potassium sulfate, 28 parts of deionized water;

[0045]II. Add ethyl acrylate and methacrylic acid into ethanol, stir and dissolve to obtain liquid A;

[0046] III. Add sodium itaconate, sodium styrene sulfonate, tetrasodium iminodisuccinate, and potassium persulfate into deionized water, stir and dissolve to obtain liquid B;

[0047] IV. After mixing liquid A and liquid B evenly, transfer them to a reaction kettle, and carry out a copolymerization reaction at 100°C for 6 hours to obtain a modified polyacrylate emulsion;

[0048] S2: Weigh 15 parts of sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com